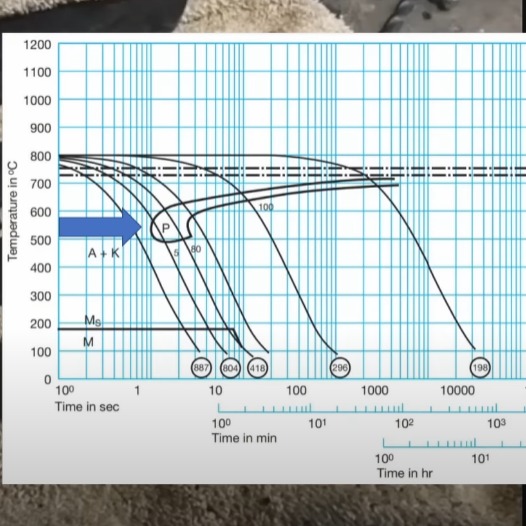

H13 Tool Steel: Properties, Applications, and Machining Considerations

AISI H13 is a versatile alloy. It is preferred for applications like hot forging, die casting and extrusion. These require high-temperature steel and die steel. It is widely employed in injection molding and die casting production. More information about

Jul 26,2024

Jul 26,2024

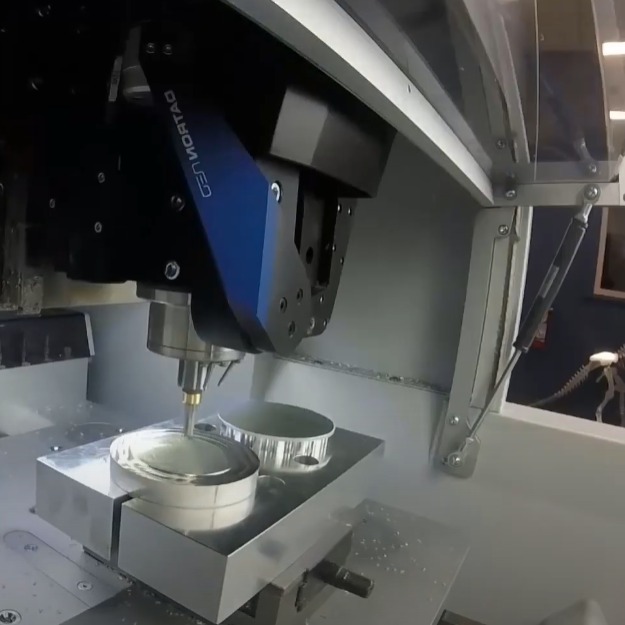

CNC Machining Espresso Machine Parts List: Process & Surface Finish

This article will provide detailed information about the espresso machine part list, process and surface finish of espresso machine by CNC machining.

Mar 25,2025

Mar 25,2025

Coarse Thread vs. Fine Thread: From Design to Manufacturing

Correct threading type would serve the purpose of the screws better. Let's explore the topic of coarse thread vs fine thread, and know more about theirs dasign and manufacturing!

Mar 18,2025

Mar 18,2025

Bolt vs Nut: A Global Standard Comparison (ISO, DIN, ASTM)

This is an article about Bolt vs Nut comparison. You can learn more the differences and functions about bolts and nuts(global/national standards).

Mar 17,2025

Mar 17,2025

3/8 16 Tap Drill Size Explained: How to Achieve Precision Threads Every Time

This article introduces 3/8 16 Tap Drill Size, its applications and materials from the perspective of precision threads.

Feb 22,2025

Feb 22,2025

M Codes for CNC: Function, Types&Uses

This article will introduce M Codes for CNC from the aspects of functions, types and uses. This will help you better understand the codes used in CNC processing!

Feb 19,2025

Feb 19,2025

What are G-Codes in CNC? Programming and Commands

This article will focus on answering the question of what are G-Codes in CNC, and further explore it from the perspective of programming and commands.

Feb 14,2025

Feb 14,2025

中国製と日本製のタップ穴精度の違い:標準差がもたらす影響と解決方法

タップ穴の精度は、部品の組み立てや機能に大きな影響を与えます。特に日本市場では、精度に対する要求が非常に高く、適切な基準を満たさない製品は信頼性に欠けると見なされがちです

Feb 08,2025

Feb 08,2025

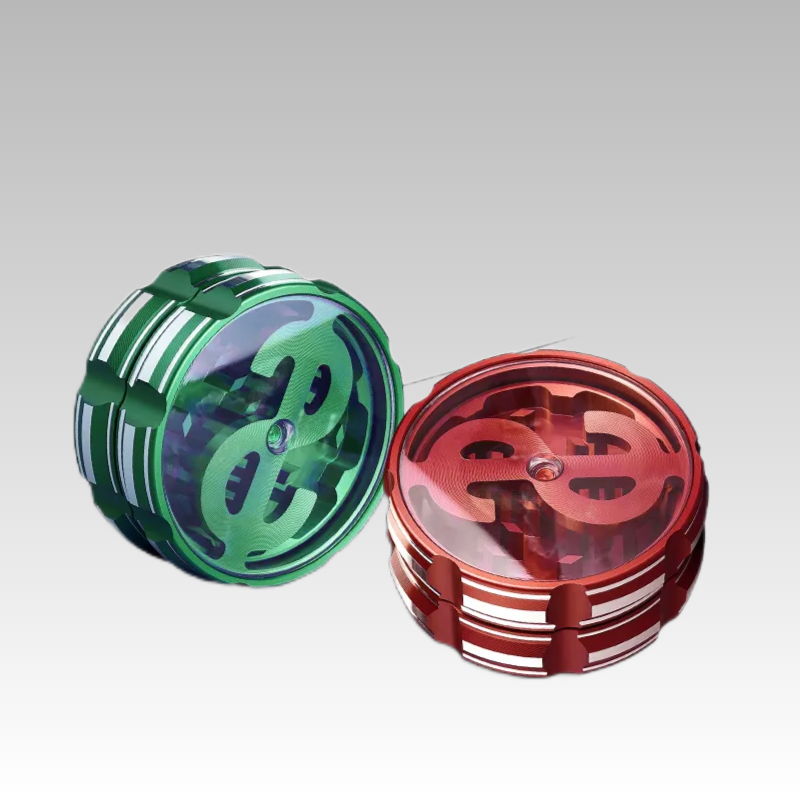

Wholesale Custom Herb Grinders and Accessories

High-quality grinders enhance the taste of herbs and let you enjoy more the flavour. Grinders control how fine or coarser the size of the pieces of plant material. Herb grinders are normally made of wood, metal and plastics and have a range of color and s

Dec 05,2024

Dec 05,2024

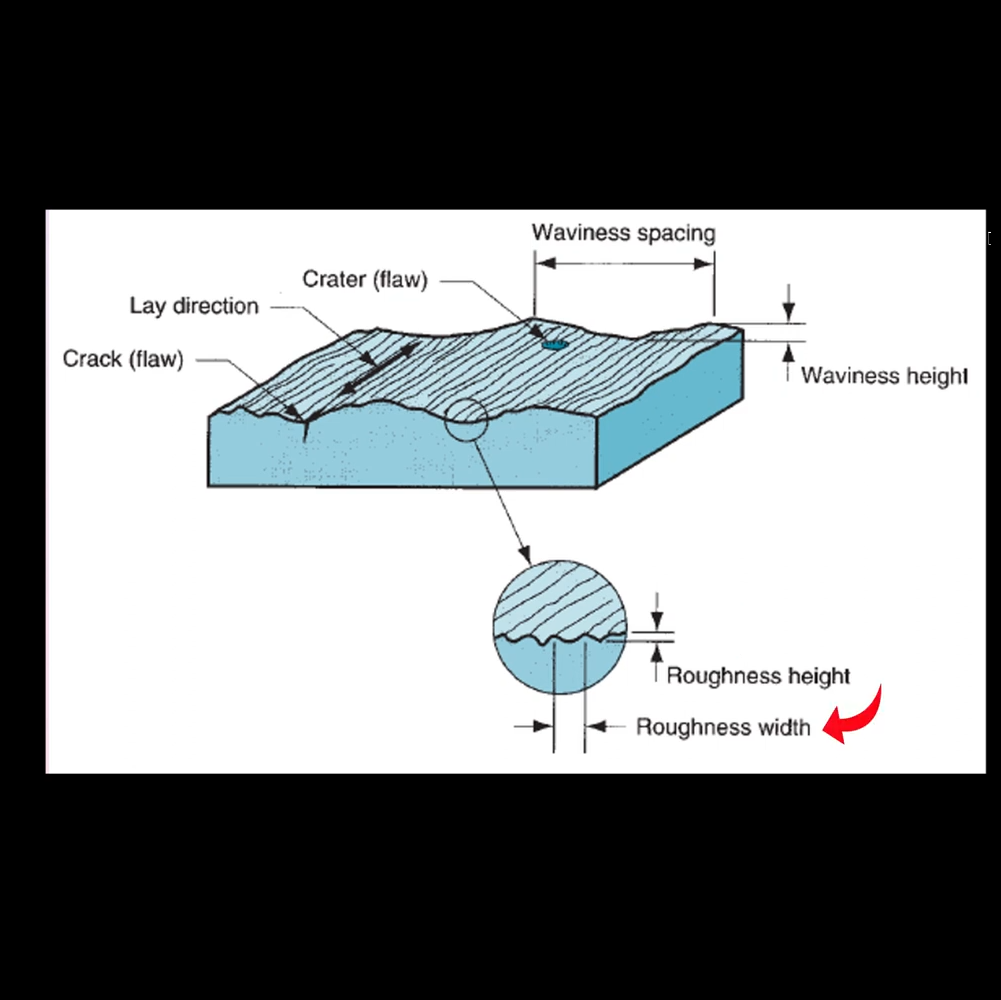

RA 6.3 Surface Finish: Definition and Applications

What is RA in Surface Finish?

In the case of surface finish, RA means the roughness average. Its values are represented with the µm units. Its value shows how the surface is smooth like the peak-to-valley d

Nov 19,2024

Nov 19,2024

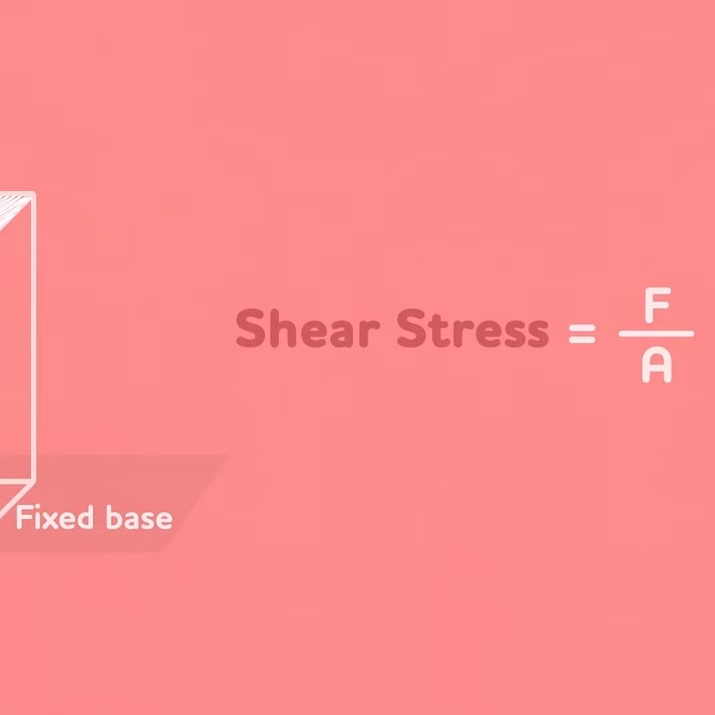

Shear Stress in Physics: Formula, Calculate, and Applications

Shear stress, or tangential stress, occurs when forces cause material layers to slide parallel to each other. Essential in physics and engineering, it helps predict deformation and failure in materials. This blog covers its definition, formulas, and real-

Nov 19,2024

Nov 19,2024

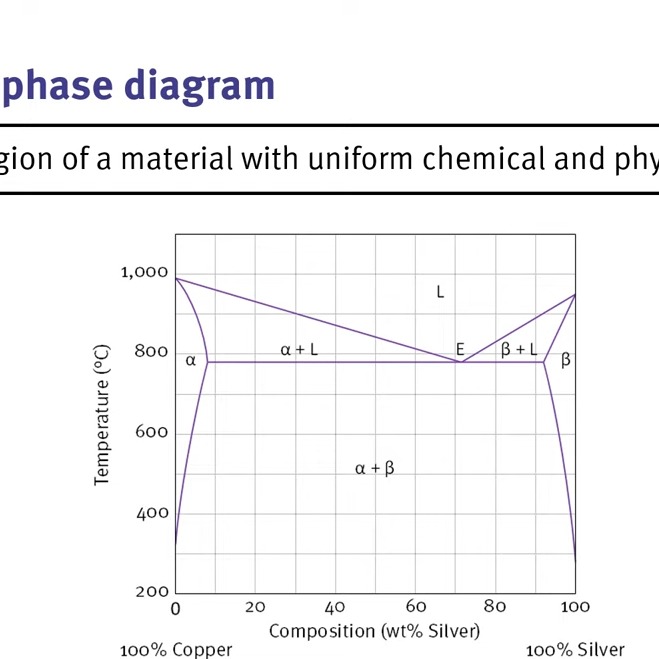

Iron Carbon Phase Diagram: Definition, Phases, and Applications

The Iron-Carbon Phase Diagram is super important in materials science. It shows how different temperatures & carbon amounts change the phases of iron and its alloys. When engineers get this diagram, they can make steel even better, which helps in many

Nov 15,2024

Nov 15,2024

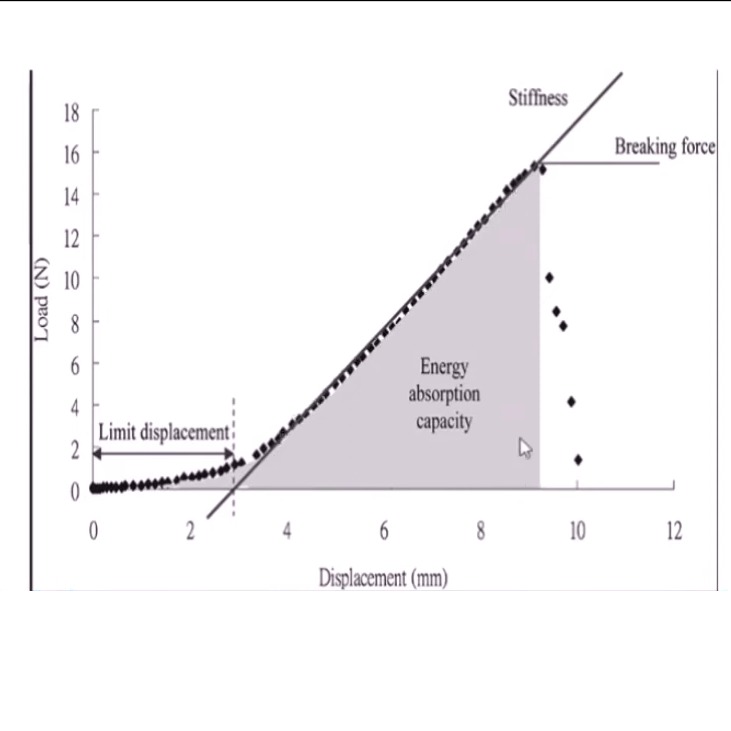

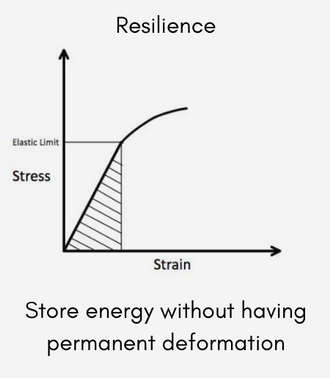

Modulus of Resilience: Formula, Calculation, and Key Materials

Modulus of resilience is the ability of a material to absorb and release energy without permanent deformation, it is very important concept in materials science field and obviously important for any engineer to understand how actually materials behave und

Sep 21,2024

Sep 21,2024

Toughness vs. Resilience Material: Comprehensive Guide

Solid material can absorb energy during deformation. The degree of deformation could be different which varies the energy requirement in material. This energy is measured by two different properties in material, known as resilience and toughness. Both are

Sep 16,2024

Sep 16,2024

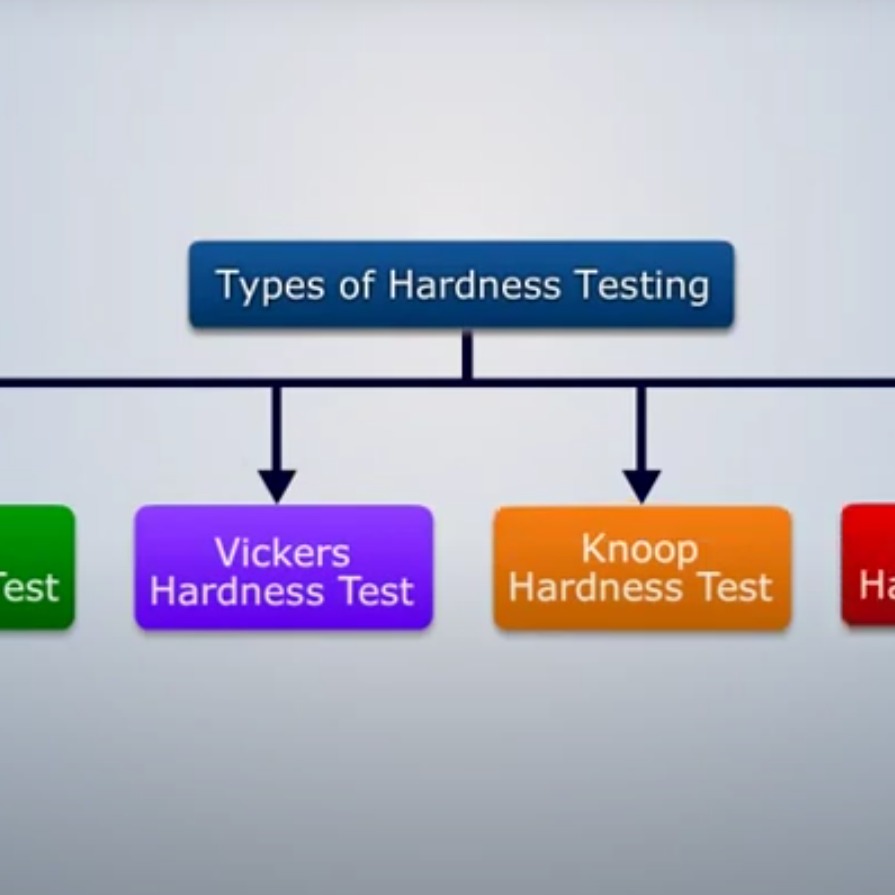

Metal Hardness: Charts, Processes, and Testing

Material hardness is a property to identify the indentation resistance and scratch resistance of surface. The hardness measurement determines the denting resistance from impact. This is in correlation with ductility and material hardness. Material will be

Aug 23,2024

Aug 23,2024

A Complete Guide To Blackened Steel. Plus How To Blacken Steel

Blackened steel has become a popular material choice in modern design and architecture, offering an aesthetically pleasing, durable finish that enhances the visual appeal of both residential and commercial spaces. Whether you're a professional in the

Aug 21,2024

Aug 21,2024

Top 6 Important Aerospace Component Manufacturing Processes in 2025

Aerospace manufacturing is rapidly evolving with new technologies and materials that drive the development of high-performance components. To stay competitive in this dynamic field, understanding the latest advancements in manufacturing processes is essen

Aug 19,2024

Aug 19,2024

8 Methods to Heat Treat 17-4 PH Stainless Steel

17-4 PH grade of stainless steel is a metallic material which possesses several characteristics making it a preferred choice in high temperature applications. Major properties that make this alloy famous include exceptional formability, weldability and co

Aug 15,2024

Aug 15,2024

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address