3/8 16 Tap Drill Size Explained: How to Achieve Precision Threads Every Time

Feb 22,2025

Feb 22,2025

When you’re working on threads, especially for 3/8 16 sizes, choosing the right tap drill size is crucial. Getting the size right ensures that your threads are strong, precise, and reliable. In this article, we’ll break down why the 3/8 16 tap drill size is so commonly used, how to choose the right one, and the mistakes you need to avoid to make sure your threads come out perfect every time.

What is the 3/8 16 Tap Drill Size?

To understand why 3/8 16 is such a popular size, it’s important to know what it means. A 3/8 16 tap drill size refers to a thread size where the diameter is 3/8 inch, and the threads per inch (TPI) are 16. This makes it a standard thread size for bolts and screws, ideal for a variety of industries and applications.

Why 3/8 16 is a Common Thread Size

The 3/8 16 tap drill size refers to the thread size where the diameter is 3/8 inch, and the threads per inch (TPI) are 16. This size is commonly used for bolts and screws, making it an essential part of machining and manufacturing. Its popularity arises from the fact that it strikes a balance between strength, size, and ease of use, making it versatile in various applications, from automotive to construction.

Standard vs Custom Tap Drill Sizes for 3/8 16

In most cases, a standard 3/8 16 tap drill size is used, which provides a good fit for typical materials. However, for specialized applications, a custom tap drill size might be necessary to achieve the best performance. Custom sizes are often required when dealing with materials that have unique properties or when precision is crucial for particular use cases. Choosing a custom size helps ensure that the threads are precise, strong, and capable of withstanding high-stress environments.

The Importance of Choosing the Right Tap Drill Size

Now that we know what 3/8 16 refers to, let’s talk about why choosing the right tap drill size is so important. The wrong drill size can affect the quality of your threads, and that can lead to weak connections or even failure. Let’s see how incorrect drill sizes can cause problems.

How Incorrect Drill Size Affects Thread Quality

Using an incorrect drill size can have a significant impact on thread quality. If the drill size is too large, it will result in threads that are too shallow, leading to poor grip and weak connections. Conversely, if the drill size is too small, it can cause the threads to be too tight, which could lead to stripped threads or damage to the material. It is important to get the drill size just right to ensure strong and reliable threads.

Why Precision Is Crucial for Strong and Reliable Threads

Precision in selecting the right tap drill size ensures that the threads are uniform and secure. If the threads are not cut correctly, the fastener may not hold securely, leading to potential failures, especially in high-stress applications. Proper precision is essential to ensure that the parts fit together tightly and maintain their integrity over time.

How the Right Drill Size Prevents Thread Damage

The right drill size prevents damage to the threads, which can occur when the thread is too tight or too loose. Ensuring that the tap drill size is correct helps prevent issues like cross-threading, where the fastener fails to engage correctly with the threaded hole. It also reduces wear and tear on the tap, increasing the lifespan of the tooling and the quality of the threads produced.

Step-by-Step Guide to Selecting the Right 3/8 16 Tap Drill Size

Finding the right tap drill size doesn’t have to be complicated. We’ve put together a simple guide to help you get it right. This section will walk you through the steps for calculating the correct size, and we’ll share some recommendations based on the material you’re working with.

Calculating Tap Drill Size for 3/8 16 Threads

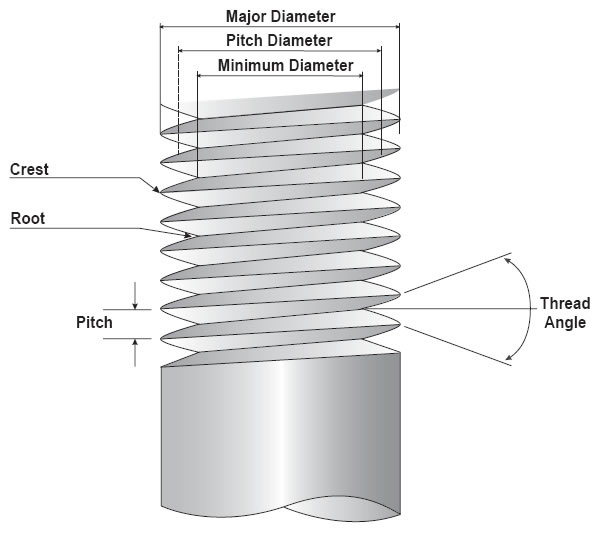

To calculate the tap drill size for a 3/8 16 thread, you need to know two things: the major diameter of the thread (3/8 inch) and the pitch, which is 16 threads per inch. Use this formula:

Tap Drill Size = Major Diameter - Thread Pitch

For 3/8 16 threads, the math looks like this:

Tap Drill Size = 0.375 inches - 0.0625 inches = 0.3125 inches (5/16 inches)

So, for 3/8 16 threads, a 5/16-inch drill bit is what you need.

Common Drill Bit Sizes for 3/8 16 Tapping

For most materials, a 5/16 inch drill bit works well. But some materials might need slightly different sizes. For example, when working with tougher materials like steel, you might need a slightly larger drill bit. Here’s a quick guide:

| Material Type | Recommended Drill Size |

|---|---|

| Aluminum | 5/16 inch (0.3125 inches) |

| Steel | 19/64 inch (0.2969 inches) |

| Plastic | 9/32 inch (0.2813 inches) |

Adjusting for Material Type and Hardness

The material you’re working with plays a big role in choosing the right drill bit. Softer materials, such as aluminum, won’t require as much material removal, so the standard size usually works. But harder materials like steel or titanium may require a slightly larger drill to allow the tap to form clean threads. Always adjust based on the material’s hardness to make sure you get the best results.

Mistakes to Avoid When Selecting 3/8 16 Tap Drill Size

Selecting the correct drill size is crucial, but there are also several common mistakes you’ll want to avoid. Let’s take a look at these pitfalls and how to steer clear of them.

Using a Drill Bit Too Large for 3/8 16 Threads

If you use a drill bit that’s too large, the threads will lack the grip they need. This leads to weak threads that could slip or fail under pressure. Stick to the recommended size to avoid this issue.

Using a Drill Bit Too Small and Its Consequences

On the other hand, a drill bit that’s too small will create tight threads. This can cause stress on the material and damage the threads. In some cases, it may even strip the threads, making the hole unusable.

Ignoring the Effect of Thread Pitch on Drill Size

Thread pitch refers to the distance between threads. If you ignore this when selecting your drill size, you might end up with threads that don’t fit properly. Always account for the pitch to ensure the correct fit and functionality.

3/8 16 Tap Drill Size vs. Thread Size

Understanding the difference between tap drill size and thread size is key to getting the perfect fit. In this section, we’ll explain why the tap drill size is always slightly smaller than the thread size and how this impacts the final thread quality.

The Difference Between Tap Drill Size and Thread Size

The tap drill size is smaller than the thread size because it’s the hole that guides the tap as it cuts the threads. The thread size is the full diameter of the threaded area, while the tap drill size is the hole that needs to be prepared first.

Why Tap Drill Size is Slightly Smaller Than Thread Size

The reason for this difference is simple: the tap needs space to form the threads properly. If the drill size were the same as the thread size, there wouldn’t be enough room for the tap to cut the threads correctly. The slight difference in size ensures that the threads are cut cleanly and securely.

How the Right Tap Drill Size Leads to Optimal Thread Fit

Using the correct tap drill size ensures that the threads fit perfectly. This leads to strong, reliable connections that won’t fail when subjected to stress. It’s the key to achieving a perfect thread fit every time.

How to Achieve Precision with Your 3/8 16 Tap Drill Size

Achieving precision requires more than just selecting the right drill size. This section covers additional steps you can take to make sure your threads are as precise as possible.

Ensuring the Correct Hole Depth for 3/8 16 Threads

The hole depth is just as important as the drill size. If the hole is too shallow or too deep, the threads won’t form correctly. Make sure the hole depth is just right to accommodate the full length of the threads without overcutting.

Using Proper Tapping Tools for Precision Results

Using the correct tapping tools is critical for precision. Ensure that the tap is the right size and is in good condition. Using a dull or worn-out tap can lead to poor thread quality.

Calibration Tips for Consistency in Thread Cutting

For consistent, high-quality threads, regular calibration is a must. Check your taps before use, ensure the machine is properly set up, and verify that the drill and tap sizes are correct. Calibration helps maintain the same high-quality results throughout the project.

Material Considerations for 3/8 16 Tap Drill Size

The type of material you're working with can change the way you approach tap drilling. Let’s go over how different materials affect your drill size selection.

Adjusting for Soft vs Hard Materials

Softer materials, like aluminum, are easier to work with and typically need a smaller drill size. Harder materials, like steel, may require slightly larger drills to allow the tap to cut clean, deep threads.

Special Considerations for Metals, Plastics, and Composites

Each material behaves differently when being tapped. Plastics may need a smaller hole to prevent the material from over-expanding, while metals may require more force. Composites often require special drilling techniques to avoid cracking.

Why Material Type Affects Your Tap Drill Size Choice

The material type influences how much force is required during drilling and tapping. Softer materials don’t require as much force, so the drill size remains consistent. However, tougher materials often need adjustments to ensure the threads are cut properly.

Cutting Fluids and Their Role in Achieving Precision Threads

Cutting fluids help improve the tapping process, making it easier to form clean threads. Let’s look at why cutting fluids are essential and how they can help you achieve better results.

The Importance of Using the Right Cutting Fluid

Using the right cutting fluid reduces heat and friction, which helps prevent the tap from overheating and wearing out too quickly. It also allows for smoother thread formation and reduces the risk of thread damage.

Common Cutting Fluids for 3/8 16 Tapping

Common cutting fluids include oils, emulsions, and water-soluble fluids. The type of cutting fluid you choose depends on the material you're working with and the machine you’re using. Oils are generally used for tougher materials, while water-based fluids work well for softer materials.

How Cutting Fluids Help Prevent Tool Wear and Thread Damage

Cutting fluids lubricate the cutting process, which helps reduce the wear on both the tool and the material. This lubrication also prevents the threads from being damaged during the cutting process, ensuring clean and accurate threads every time.

Conclusion

Choosing the right 3/8 16 tap drill size is crucial for producing strong, reliable threads. By understanding how to calculate the correct size, considering material types, and avoiding common mistakes, you can achieve precision threads every time. Make sure to follow the tips in this article to ensure that your threads fit perfectly and perform well.

FAQs

What is the ideal tap drill size for 3/8 16 threads?

The ideal tap drill size for 3/8 16 threads is typically 5/16 inches (0.3125 inches). This size provides the perfect balance for clean, precise threads.

Can I use the same tap drill size for different materials?

While the basic tap drill size remains the same, adjustments may be needed based on material type. Softer materials often require a slightly smaller size, while harder materials may require a slightly larger drill.

How can I prevent tap damage when tapping 3/8 16 threads?

To prevent tap damage, always use the right size drill bit, keep your taps sharp, and use proper cutting fluids. Regular calibration also helps maintain consistent results.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

German

German French

French Spanish

Spanish Russian

Russian Arabic

Arabic Norwegian

Norwegian Dutch

Dutch Finnish

Finnish Japanese

Japanese Chinese (Simplified)

Chinese (Simplified) Home

Home

Bolt vs Nut: A Global Standard Comparison (ISO, DIN, ASTM)

Bolt vs Nut: A Global Standard Comparison (ISO, DIN, ASTM)