1095 Steel for Knives Making: Beginners Guide

1095 steel is a great choice for making strong, sharp knives. In this guide, you will learn why 1095 steel is popular, its benefits, and how to use it. From heat treating to sharpening, this guide will show you how to work with 1095 steel to create long-l

Sep 10,2024

Sep 10,2024

304 Stainless Steel: Properties, Fabrication, and Applications

If you are searching for the best grade of all steel grades which requires high strength and corrosion resistance, then this article is going to be helpful for you. Stainless steel 304 is one of the most used which accounts for more than 50% of all stainl

Sep 03,2024

Sep 03,2024

Damascus Steel vs. Carbon Steel Knives: Which is the Better?

Damascus knives and carbon knives are very popular among professional chefs. Damascus knives are fancy and pattern-welded knife. it is also known as layered steel knife. While carbon knives are durable and reliable. But the knife selection is based on som

Sep 02,2024

Sep 02,2024

18/8 Stainless Steel: Properties, Uses & Comparisons

18/8 is also known as 304 stainless steels. AISI standard has designated the steel as 18/8. It is one of the most common and versatile materials in stainless steel grades. It has high corrosion resistance, durability and aesthetically appealing due to chr

Sep 02,2024

Sep 02,2024

All About D2 Steel: Properties, Composition, and Knife Applications

D2 tool steel is a semi-stainless steel. In industrial tooling, specifically in custom knife making field, D2 steel stands out as a preferred material among manufactures and artisans. It is famous for its high edge retention, wear resistance, and hardness

Aug 29,2024

Aug 29,2024

A Comprehensive Guide to AISI 1045 Medium Carbon Steel

AISI 1045 steel is known for its good welding, machining, features and high strength and impact resistance. It is utilized in tempering or induction hardening conditions to achieve surface hardness up to 60HRC. It is supplied in hot rolled and normalized

Aug 27,2024

Aug 27,2024

S35VN Steel: Why It is a Top Choice for Knives

S35VN Steel is famous for its toughness and wear resistance. This is due to a combination of unique elements in alloy composition which makes it an outstanding knife steel with high cutting performance. This high carbon steel is suitable for many indoor a

Aug 24,2024

Aug 24,2024

Zinc Plated vs. Stainless Steel: Which Material is Right for Your Application?

In the world of manufacturing and design, material selection is one of the most critical decisions you can make. The materials you choose will directly impact the performance, durability, and cost-effectiveness of your products. Two of the most commonly d

Aug 21,2024

Aug 21,2024

T6 Temper Aluminum: A Comprehensive Guide for Engineers and Machinists

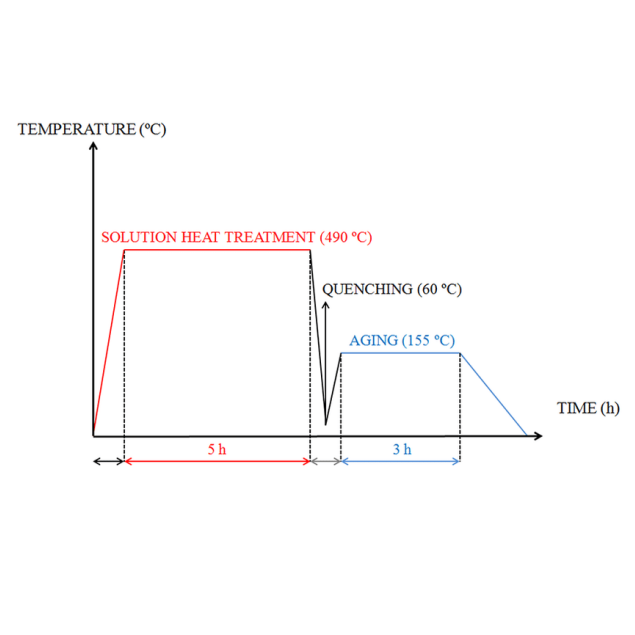

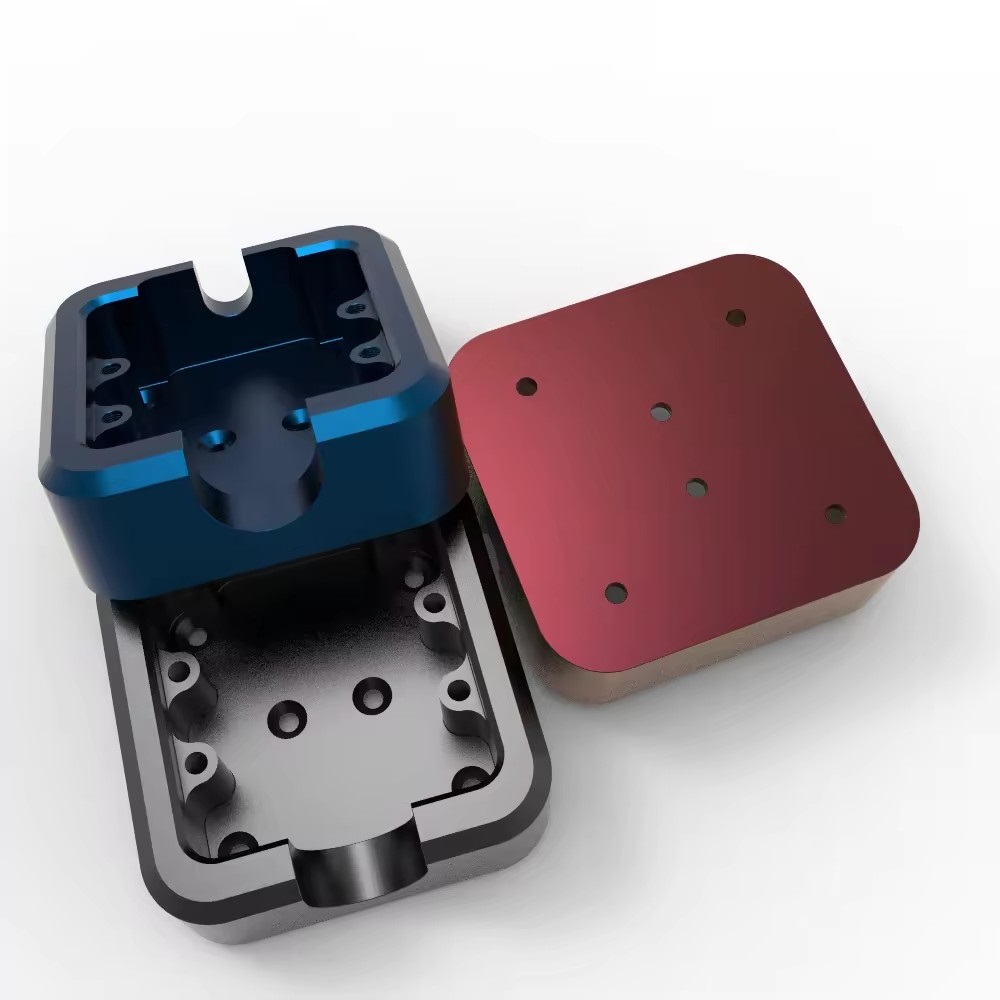

The durability and strength of T6 aluminum is enhanced by heat treatment process.For precise manufacturing and improved machine understanding T6 tempering is very important for machinists and engineers. T6 aluminum improves aluminum strength and makes its

Aug 19,2024

Aug 19,2024

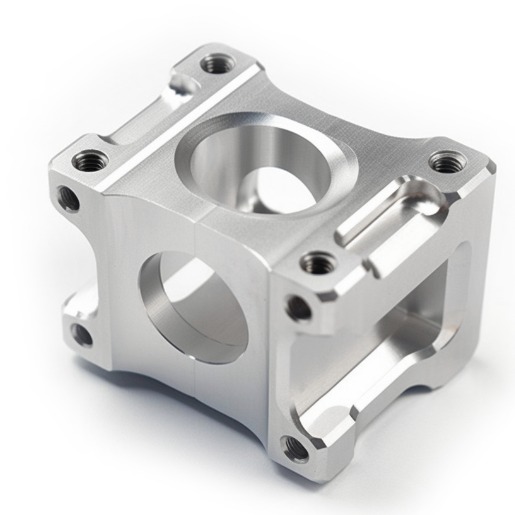

6061-T6 Aluminum: The Engineers Guide

6061-T6 aluminum strength and light weight property make it different from other aluminum alloys. High strength to weight ratio of 6061-T6 Aluminum makes it ideal for aircraft applications. This article would help you to choose 6061-T6 Aluminum for desire

Aug 15,2024

Aug 15,2024

What is the Difference Between 7075-T6 and 7075-T62 Aluminum?

Aluminum alloy 7075 is known for its exceptional strength and is widely used in aerospace, automotive, and high-performance applications. Among the various tempers of 7075, T6 and T62 are two common designations, each representing different heat treatment

Aug 14,2024

Aug 14,2024

Comprehensive Overview of CPM 10V Steel

In the world of high-performance tool steels, CPM 10V steel stands out. It is a superior choice for both industrial applications and knife making. Its unique properties are derived from advanced powder metallurgy. These properties make it indispensable fo

Aug 07,2024

Aug 07,2024

O6 Steel: Properties, Uses and Heat Treatment

In the manufacturing and industrial sectors, selecting the appropriate tool steel is paramount. This ensures efficiency, durability, and cost-effectiveness. Tool steel is crucial in the manufacturing industry due to its hardness, wear resistance, and abil

Nov 24,2024

Nov 24,2024

What is S5 Tool Steel? Tuofa CNC Machining

Tool steels are a group of carbon and alloy steels. They are particularly well-suited to be made into tools. Their suitability comes from their distinctive hardness, resistance to abrasion, and ability to hold a cutting edge at elevated temperatures. Amon

Aug 02,2024

Aug 02,2024

6061 T6511 Aluminum: The Ultimate Guide

6061 T6511 Aluminum is used widely for engineering applications because of its precision machining. 6061 T6511 temper aluminum shows ease of fabrication, versatility, excellent corrosion, and mechanical properties. The amazing properties of heat-treated 6

Aug 01,2024

Aug 01,2024

S7 Steel: Properties, Uses, and Heat Treatment

S-7 tool steel is an air-hardening, cold work steel. It is known for its exceptional toughness and shock resistance. This material was developed to withstand high-impact and heavy-duty applications. S-7 tool steel is widely used in various industries. The

Nov 17,2024

Nov 17,2024

What is 8620 Steel? Complete Guide 2025

AISI 8620 alloy is known for its high corrosion and wear resistance and strength. This is due to its unique chemical composition. It is mostly employed in oils rigs for drilling. There is a lot more about SAE 8620 steel if you are working with this materi

Jul 30,2024

Jul 30,2024

Understanding 2000 Series Aluminium Alloys in Aerospace

The 2000 series aluminium alloys are primarily alloyed with copper. They are fundamental to aerospace engineering. They offer high strength, excellent machinability, and superior fatigue resistance. These properties make aluminium parts indispensable

Jul 26,2024

Jul 26,2024

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address