Modulus of Resilience: Formula, Calculation, and Key Materials

Sep 21,2024

Sep 21,2024

Modulus of resilience is the ability of a material to absorb and release energy without permanent deformation, it is very important concept in materials science field and obviously important for any engineer to understand how actually materials behave under different conditions. You will learn about the concept of modulus of resilience, its formula and calculation and other key materials.

So, let’s start with thorough explanation:

What is Resilience?

In simple words, resilience means to bear any stress or pressure etc. Modulus of Resilience is the concept of Materials Science field which deals with how materials behave under stress, temperature and in all other conditions. This concept illustrates the ability of materials to absorb or release the energy but without permanent deformation. Like this concept directly says high modulus of resilience means the higher ability of material to withstand difficult conditions without losing the actual shape.

Resilience Defined in Engineering and Materials Science?

In this field, Resilience of any material means that how it behaves when it is under stress or when stress is released. This concept clarifies which material is best in loading conditions because that material would retain its original properties and hence the original other properties would be.

Energy Absorption in Resilient Materials

Under elastic limits, any material absorbs energy when it is loaded and then releases that energy to come back in its original position when load is removed. So, the higher the resistance of any material, it means that material has the higher energy absorption.

Role of Resilience in Civil and Mechanical Engineering

In these fields, this property of materials ensures the reliability and durability of materials. In civil and Mechanical Engineering, structural designs and components which are directly linked to impact-damage and vibrations etc. need this property of materials in higher amounts so that materials do not fail during application.

What is Modulus of Resilience?

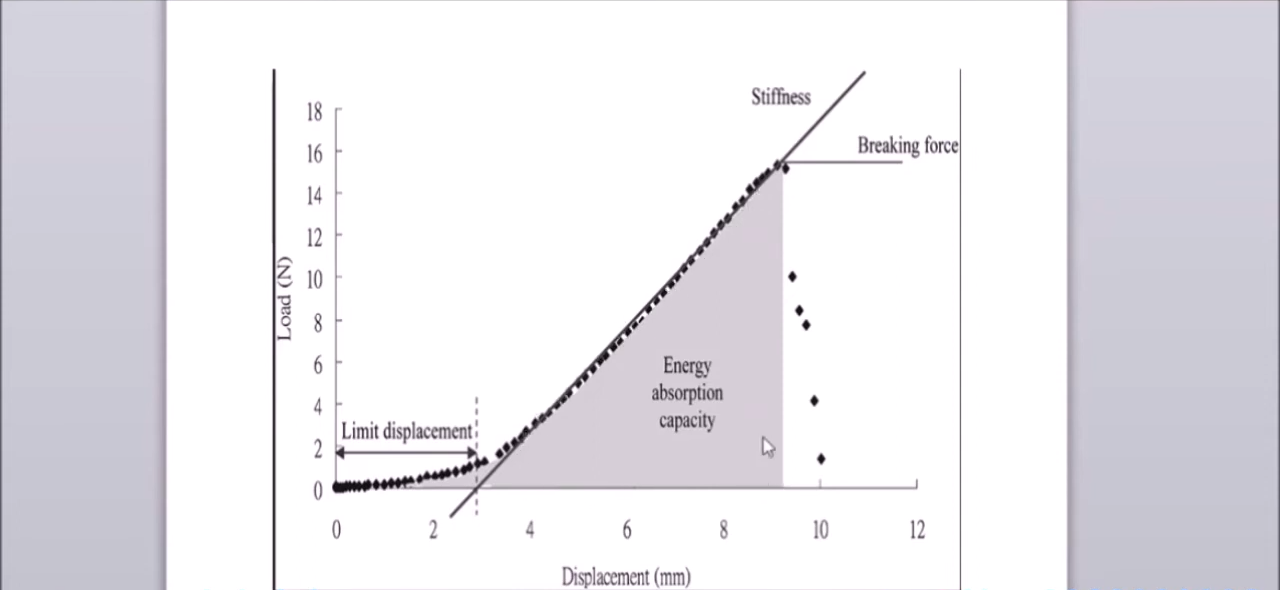

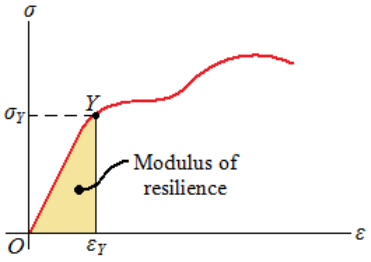

It is an important property of materials which means the total amount of energy absorbed per unit volume of material without permanent deformation. It means that materials would not deform if the value of modulus of resilience is high. It can be seen through the following graph:

It is calculated by the area under elastic region of material’s stress-strain curve. This property of materials helps you in selecting materials which are going to be used in load, impact damage or vibrations related applications.

Definition of Modulus of Resilience in Materials Science

In the field of materials science and engineering, modulus of resilience means the maximum amount of energy absorbed per unit volume by any material within elastic limit. As it is represented in the above graph.

Resilience Modulus: Understanding Energy Absorbed per Unit Volume

Modulus of resilience means energy absorbed per unit volume within the elastic region. It means how efficiently a material can absorb or release energy within an elastic region and it’s a crucial aspect of selecting materials for load bearing etc. applications.

Key Differences Between Resilience and Modulus of Resilience

Resilience means the simple ability of material to absorb or release energy within elastic region while Modulus of Resilience means the amount of energy released or absorbed per unit volume in the elastic region. Modulus of resilience provides numerical value while resilience is just a guess.

Formula for Modulus of Resilience

Modulus of resilience is expressed through “U” and that’s how it is calculated:

U=![]()

Here,

σy shows the yield strength of the material

E shows the Young’s Modulus

Formula Explanation: σ (Stress) and ε (Strain)

The formula uses stress and strain to calculate modulus of resilience. Stress is in applied or internal load per unit volume and strain is the response to stress which is rate of deformation according to the applied stress.

Variables Used: Yield Strength and Young’s Modulus

Yield Strength is that point on stress-strain curve after which material starts to deform plastically means that deformation won’t be recovered. Young’s Modulus is the material’s stiffness. These variables reflect the energy absorption capacity.

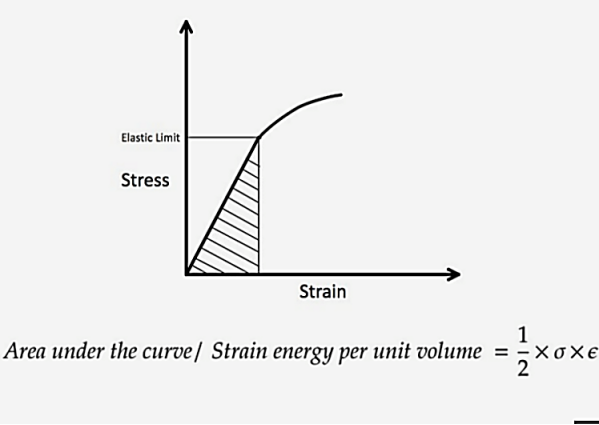

Calculation Example Using Stress-Strain Curve

In the above example, if you want to measure modulus of resilience, then you need to do two steps; one identifies the yield point and then it would become a triangle and simple measure the area under the curve i.e. triangle:

U= ½ σy X εy

σy is the yield point and εy is the responded strain.

How to Calculate Modulus of Resilience?

This is calculated through tensile testing of materials in which material is subjected to the load. A graph of stress-strain curve is generated along with applied load. Area under the curve till yield point is taken and calculated and that’s the modulus of resilience. This is very important to calculate while selecting the materials for the applications like impact-damage or load bearing etc.

Calculation Method Using Stress-Strain Diagram

Stress-strain Diagram generated through tensile test is shown below:

Calculation is simple, just calculate the area of that triangle i.e. area under the elastic limit on stress-strain curve.

Step-by-Step Process to Find Modulus of Resilience

There is total three steps which are required to find modulus of resilience:

1- Identify the yield point σy

2- Calculate the strain ε at yield point

3- Find the area under the curve

Formula: U= ½ X σy X εy

Example Calculation for Steel, Aluminum, and Other Materials

lets calculate the U for Steel:

From literature, we know the yield strength of steel is 250MPa and E is 200GPa

Applying formula:

U=![]()

U=![]()

U= 156.25 J/m3

So, the modulus of resilience for steel is 156.25 J/m3.

Units for Modulus of Resilience

You know what modulus of resilience is which means the amount of energy released or absorbed per unit volume by any material. You know the unit for energy is joule (J) and for volume is m3. So, collectively it becomes j/m3. This unit shows energy absorbed or released per unit volume under elastic region. Since it’s an important property to know for engineers that’s why its unit are too important to know that to have accurate values.

Energy Per Unit Volume: Joules Per Cubic Meter (J/m³)

This unit represents the energy absorbed or released in elastic region per unit volume. This unit illustrates how much material retains its original position when stress etc. is removed, meaning that how much this material is resilient, and it is an important factor when that must be used in structural or load bearing application etc.

SI and Imperial Units of Modulus of Resilience

There are two types of units used in different industries: imperial and SI. Imperial unit of Modulus of Resilience is inch-pounds per cubic inch (in-lb/in3) and SI unit is Joule per cubic meter (J/m3). SI units are widely used in most industries, so its important to carefully convert imperial units to SI units.

Differences Between Modulus of Resilience and Modulus of Elasticity

Modulus of resilience is how much materials remains in its original shaper when energy is absorbed or released per unit volume by that material in elastic region of stress-strain curve. While modulus of elasticity means that stiffness of the material which means how much that material is resistant to deformation under stress. Modulus of resilience focuses on energy absorption or release while modulus of elasticity focuses on how much a material is resistant.

For further information related to resilience, ductility, toughness and yield strength, you can see the following videos available on YouTube.

Modulus of Resilience in Materials

As you know it’s an important factor of materials when selecting them for application. This property means how much a material releases or absorbs energy per unit volume. Materials like steel and aluminum show higher modulus of resilience than polymers or ceramics etc. because of their microstructure. Polymers have weaker intermolecular forces than steel or aluminum etc. and ceramics are brittle, their failures are catastrophic that’s why they have lower modulus of resilience than steels. Further comparison of modulus of resilience is given below.

Modulus of Resilience for Steel, Aluminum, and Brass

These are three very common materials used worldwide in different applications from structural to aerospace.

Steel has higher yield strength and moderate elasticity which makes it more resilient than others.

Aluminum has higher elasticity than steels but has lower yield strength which makes is material of moderate resilience.

Brass has modulus of resilience in between both these steels and aluminum.

Values for Stainless Steel and 1018 Steel

These two steels are the most common in the world. Stainless Steel has a modulus of resilience of 120-150 j/m3 and this steel is used where corrosion resistance is the primary focus.

1018 steel is a low carbon steel and easier to weld and machine. This steel has a modulus of resilience of 150-160 j/m3 because of the lower amount of Carbon content.

Comparisons: Polycarbonate, ABS Plastic, and Wood

These materials are compared with each other in terms of modulus of resilience.

|

Polycarbonate |

ABS Plastic |

Wood |

|

Since it’s a polymer and soft, that’s why its Modulus of resilience is 250-300 J/m3 |

This material has a modulus of resilience of 100-150 J/m3 and has greater value of toughness. |

It has a modulus of resilience 10-15 J/m3 and used in construction parts. |

Importance of Modulus of Resilience in Engineering

In engineering, the primary focus remains on the deformation of materials. You know that deformation is directly related to the safety of any part or system etc. So, this property comes in and explain that how much a particular material can absorb or release energy without permanent deformation. By knowing the value of this property, you will get to know at which point this material starts getting deformed permanently and hence you make that point as a threshold value to use. Hence, due to this property you will enhance your safety because you know the point where material starts to deform. That’s why modulus of resilience is important in engineering.

Application in Civil and Mechanical Engineering

In civil engineering, this property of materials helps in selecting materials for making bridges etc. where you know stress is applied by multiple things like wind, earthquake and traffic etc. In mechanical engineering, this property of materials helps in selecting the materials when their application is related to load bearing and shock absorber etc. simple is that where energy is released or absorbed, this property of materials going to help you.

Resilience and Modulus of Resilience in Structural Design

As you know, simple resilience means that energy absorption or release in elastic region while modulus of resilience means that energy absorbed or released per unit volume in elastic region. So, in structural design, the latter is more important because it gives more practical and accurate values.

Why Modulus of Resilience Matters for Energy Absorption?

This property of materials matters because this property decides that how much a material will absorb or release energy per unit volume under elastic region when it is stressed. This property decides the uses of materials in different energy absorption or release related applications like spring, shock absorber etc.

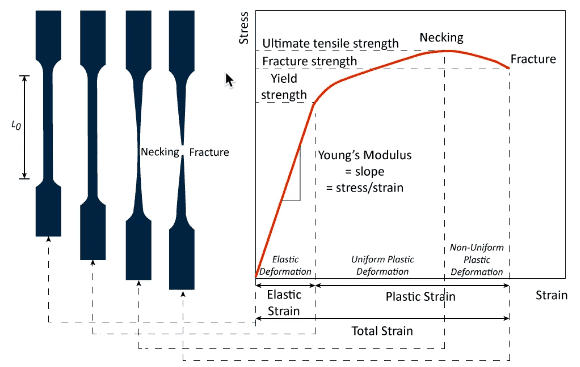

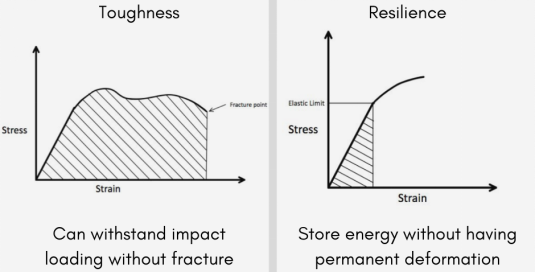

Modulus of Resilience vs. Toughness

Modulus of Resilience means energy absorbed or released only in elastic region on the stress-strain curve means area under the curve till the yield point, while toughness means the whole area under the stress-strain curve which means how much a material can absorb energy when it is stressed to its fracture point. As the following graph represents:

Graphical Explanation of Modulus of Resilience vs. Toughness

Here, you can see toughness means to fracture point and resilience means only in elastic limit.

How to Measure Resilience and Toughness

According to the above graphs, resilience is measured through area under the curve till the elastic limit and for that we need yield strength and modulus of elasticity.

Toughness is measured through by measuring whole area under the stress-strain curve.

Differences Between Proof Resilience and Modulus of Resilience

Proof resilience is the overall total amount of energy released or absorbed in elastic region. It is expressed as absolute terms like joules (J) etc. while modulus of resilience is the amount of energy absorbed or released per unit volume in elastic region and it is expressed as J/m3 .

Factors Affecting Modulus of Resilience

Modulus of resilience means energy absorbed or released per unit volume in elastic region. There are many factors which affect it and some of them are discussed briefly here:

The primary factor which affects “U” is the composition of materials which make them resilient, ductile or brittle etc.

Then grain size which is inversely proportional to “U” and temperature. At lower temperatures, resilience of materials tends to decrease. Then the loading rate, if it is higher then resilience will decrease.

Temperature Effects on Modulus of Resilience

At higher temperatures, materials become more ductile due to which their resilience increases but elasticity is reduced while at lower temperatures, materials become brittle, their elasticity increases but resilience decreases. It means at higher temperature; materials have a higher tendency to recover when the stress is removed.

Influence of Material Composition and Processing on Resilience

These factors are the most important factors which affect resilience. In case of composition, alloying of elements changes the resilience by changing the composition for instance, C increases hardness thus reduces the resilience.

Processing includes quenching, annealing and normalizing. Each heat treatment process produces a different grain structure which alters the resilience. For instance, quenching produces very fine grain structure which causes reduction in resilience.

Strain Rate Sensitivity

Strain rate sensitivity means that how rate of deformation affects the mechanical properties of materials. Polymers have higher strain rate sensitivity which means that during fast loading, strength of polymers increases and materials which are brittle like ceramics break during fast loading which means that ceramics have lower strain rate sensitivity.

Cyclic Loading and Fatigue

Cyclic loading is the cause and fatigue is its result. cyclic loading means repetition of cycles of stress over time which leads to fatigue. In fatigue failure, micro cracks generated from repetition of stress accumulate and become greater cracks which lead to fracture.

Permanent Deformation and Elastic Limit

During elastic limit, materials deform when stress is applied but they comeback to their original position when stress is released, when a yield point comes after the elastic limit. After yield point, plastic means permanent deformation starts means no recovery happens. This permanent deformation continues till the fracture point.

Related Concepts

There is total 4 concepts related to resilience which are discussed below:

Ductility means the extent to which material can deform before fracture.

Toughness means total energy absorbed by the material till fracture. Total area under the stress-strain curve is toughness.

Elasticity means recovery of deformation when stress is removed.

Yield strength means the point after which plastic deformation starts.

Damping Capacity

Damping capacity means the ability of material to dissipate and absorb energy from vibrations or shocks as heat. Materials with high damping capacity are used where high vibrations occur like in different manufacturing processes.

Energy Storage and Recovery Systems

These systems capture, store and release energy for later use and improvement. These systems include batteries, supercapacitors and flying wheels. These are widely used in renewable energy and grid stabilization.

Applications in Specific Industries

Almost all industries require resilience.

In automotive industries, highly resilient materials are used in suspension and Impact-resistant to absorb vibrations and stress.

In construction industry, resilient materials are used where the danger of earthquakes is high to absorb seismic energy.

In the sports industry, resilience enhances safety like in the case of helmets.

Aerospace and Automotive

In these fields, resilient materials are required primarily to enhance the safety of components or the product because they are essential to absorb vibrations and shocks. These materials are used in gears, wings and fuselage etc.

Spring Design

In designing the spring, you need materials which can absorb energy means should have high resilience. During designing the spring these are the important parameters: Dimensions like wire and diameter, manufacturing processes like winding or coating and then stiffness.

Why Choose Tuofa China for Your CNC Machining and Material Testing Needs?

So, after all discussion, you should chose the Tuofa China for your CNC machining and material testing because of our expertise in modulus of resilience and material properties. We offer you the best quality custom CNC tailored for high-performance and provide reliable engineering support with precise testing. We help you with our comprehensive approach ensures optimal performance and accuracy in your projects, making you a trusted partner for your technical needs.

FAQs about Modulus of Resilience

Following questions are the frequently asked questions, which are concisely discussed below:

How to Find Modulus of Resilience from Stress-Strain Graph?

Find elastic point on stress-strain curve and then it would become a triangle then just measure its area. You would need two things to know before you find Resilience one the yield strength and second is elastic modulus.

Which Material Has the Highest Modulus of Resilience?

Some high-strength alloys and advance composites have highest modulus of resilience. Titanium alloys exhibit high modulus of resilience because they can absorb or release high amount of energy without permanent deformation.

What’s the Difference Between Modulus of Elasticity and Resilience?

Modulus of elasticity means stiffness which means how much a material can resist deformation. Modulus of resilience means how much a material can absorb or release energy per unit volume in the elastic region.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Iron Carbon Phase Diagram: Definition, Phases, and Applications

Iron Carbon Phase Diagram: Definition, Phases, and Applications