M Codes for CNC: Function, Types&Uses

Feb 19,2025

Feb 19,2025

M codes and G Codes play a very crucial role in the automation in manufacturing using CNC machines. If CNC machine is analogous to a car, M Codes and G Codes are its drivers. M Codes govern the various non-movement controls in a CNC machine.

What is M Code in CNC Programming?

M Codes are also known as miscellaneous codes. They define manufacturing process settings other than movement of tool. M codes facilitate the CNC machining process by telling when to stop, how much coolant to release etc.

What do M-Codes control in CNC machines?

They regulate and control machine functions like coolant settings, machine on/ off settings, spindle settings and tool change etc.

Difference Between M-Code and G-Code

M codes are used to set CNC operational parameters while G codes are used to set the tool movement parameters.

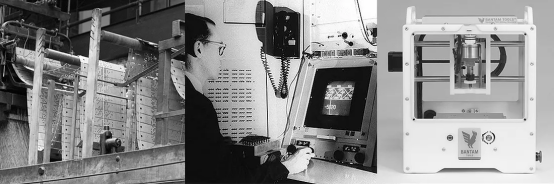

History and Importance of M-Code

Let's take a look at the origins, development and evolution of M Codes. It'll help us in understanding the necessity behind it.

- Origins of M-Code and its inventor.

While no single person can be credited with its development, the role of J Parsons is pertinent. He in collaboration with MIT developed the punched tape and positioning mechanism. That laid the foundation of numerical control (NC).

- Why M-Code is crucial for automation and precision.

M codes minimize human intervention for tasks like tool change, coolant control or spindle on/off settings etc. Without M codes the CNC machining process cannot be fully automated.

- Evolution of M-Code with CNC technology.

Since 1950s, M codes have evolved very much. Nowadays the level of evolution has reached such a level that almost every machine function is automated.

Structure and Basics of M-Code Commands

- Typical format of an M-Code command.

M Code normally start with an “M” followed by a number like M XX. “M” represents “miscellaneous” and “XX” define a specific machine function.

- Examples of basic M-Code syntax.

The most basic M Codes include M03/M04 for spindle on clockwise or anti clockwise, M08/M09 for coolant on/off and M30 for program end.

How M-Codes Work in CNC Machines

- Step-by-step explanation of M-Code execution.

M codes are machine-readable programming language. The CNC reads “M” followed by the operator, for instance “03” (for spindle control). This command is followed the machine. If there is already a command in action, the CNC will execute the new command after that.

Please check the link below for a complete practical guide:

- How M-Code and G-Code synchronize in CNC programs.

A good synchronization between M codes and G codes make the automation programming perfect. For instance, M code will instruct the CNC machine to turn the spindle on and the G Code will define the toolpath.

- Examples of M-Codes controlling machine actions.

As an example “M 03 S1500” will command the CNC to turn the spindle on at the rate of 1500 RPM.

Common M-Codes and Their Functions

Most of the M Codes used in automation programming are general and universal. But some M Codes are manufacturer specific and control specific functions. A brief of the common M Codes is given below:

General M-Codes (Universal Across Machines)

- M00 – Program Stop

- M03 – Spindle On (Clockwise)

- M08 – Coolant On

Machine-Specific M-Codes

Manufacturers like Fanuc, Hass and Siemens have slight variations in M Codes. They have their own M Codes for certain functions. Below are some of the common M Codes of these manufacturers

Fanuc M-Codes

|

M-Code |

Function |

|

M19 |

Spindle Orientation |

|

M98 |

Call Subprogram |

|

M99 |

Return from Subprogram |

Haas M-Codes

|

M-Code |

Function |

|

M17 |

Tool Turret Index |

|

M31 |

Chip Conveyor Forward |

|

M50 |

Tailstock Extend |

Siemens M-Codes

|

M-Code |

Function |

|

M29 |

Rigid Tapping |

|

M91 |

Return to Reference |

|

M110 |

Clamp Close |

CNC M-Code List by Machine Type

As already discussed above the common M Codes are almost universal across various manufacturers. It should also be kept in mind that there are certain specific M Codes for special function for which manufacturer's manual should be read. The common M Codes for CNC lathe and CNC milling machines is given below.

M-Codes for CNC Lathe

|

M-Code |

Function |

|

M00 |

Program Stop |

|

M03 |

Spindle On (CW) |

|

M04 |

Spindle On (CCW) |

|

M05 |

Spindle Stop |

|

M08 |

Coolant On |

|

M09 |

Coolant Off |

|

M30 |

Program End |

|

M41 |

Low Gear |

|

M42 |

High Gear |

|

M98 |

Call Subprogram |

|

M99 |

Return from Subprogram |

M-Codes for CNC Milling

|

M-Code |

Function |

|

M00 |

Program Stop |

|

M03 |

Spindle On (CW) |

|

M04 |

Spindle On (CCW) |

|

M05 |

Spindle Stop |

|

M06 |

Tool Change |

|

M08 |

Coolant On |

|

M09 |

Coolant Off |

|

M30 |

Program End |

|

M60 |

Pallet Change |

|

M98 |

Call Subprogram |

|

M99 |

Return from Subprogram |

Real-World Examples of M-Code in Action

M code is a set of machine-readable commands. It is an important pillar in CNC automation programming alongside the G-Codes. As an example, in precise tasks like aerospace part manufacturing, the M01 (pause function) can be intermittently used to check for errors. M08/M09 coolant control function can be used so that overheating does not cause damage to the expensive feedstock of Titanium (for instance).

Learning and Testing M-Codes with Simulators

- Overview of top M-Code simulators:

Predator Virtual CNC, Vericut, Fusion 360are top notch M code simulators. Predator Virtual CNC provides real-time multi-axis simulation. Vericut is known for its high end error detection & optimization. Fusion 360 is the easiest to use since its integrated with CAD and CAM.

- Benefits for error prevention and skill enhancement.

An expert CNC operator should have an in-depth knowledge of M Codes for critical troubleshooting or customization functions. It helps to diagnose errors quickly. Thus error prevention and mitigation becomes easy.

Safety Tips and Precautions for M-Code Programming

- Common mistakes to avoid.

Its best to make an SOP for CNC operators so as to avoid common mistakes. As an

example if the operator forgets to stop spindle (M05) before changing tool, it can result in loss. Another example is improper coolant control (M08/M09) which can cause overheating.

- Best practices for ensuring machine and operator safety.

The best practice is to follow manufacturer's manual and SOPs. Simulating the M Codes before execution can prevent errors. There should be adequate clearance for the tool to avoid collision. Above all, M00 (stop) option can be used for manual checks.

Conclusion: Why Mastering M-Codes is Essential in CNC Machining

In depth knowledge of M Codes help in timely prevention of errors. It enables CNC programmers and operators to troubleshoot easily. Further, for customized tasks, CNC programming can be edited with promptness perfectly.

FAQs

What is the easiest way to learn M-Codes?

CNC programming tutorials that explain M Code examples are available online.

Can I program CNC machines without knowing M-Codes?

CNC machines can be operated without knowledge of M codes but there could be severe hurdles in troubleshooting and M codes editing.

Are M-Codes universal for all CNC machines?

There are slight variations in M Codes operators across various manufacturers. Use of manufacturer's manual can be helpful.

What are the most commonly used M-Codes?

Common M Codes include M00 (Stop), M03/M04 (Spindle on), M05 (Spindle off) and M06 (tool change).

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

3/8 16 Tap Drill Size Explained: How to Achieve Precision Threads Every Time

3/8 16 Tap Drill Size Explained: How to Achieve Precision Threads Every Time