What is the Difference Between 304 and 321 Steel?

When selecting stainless steel for your project. it’s crucial to understand the differences. There are various grades available. Among the most commonly used stainless steels are 304 and 321. Both have distinct properties and applications, making th

Jun 20,2024

Jun 20,2024

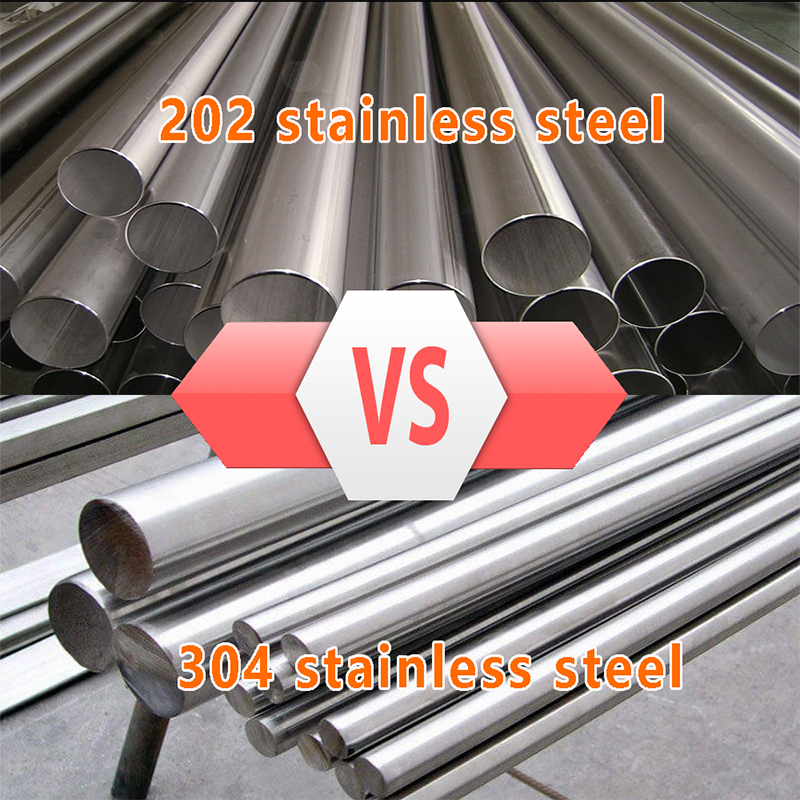

Which Steel is Best, 304 or 202? Making an Informed Decision

When it comes to selecting the right type of stainless steel for your project, understanding the differences between the various grades is crucial. Two common types of stainless steel, 304 and 202, each have unique properties and applications. This blog p

Jun 18,2024

Jun 18,2024

18/10 Stainless Steel: A Comprehensive Guide for Mechanical Engineers and Designers

Stainless steel is considered as the key stone of the modern engineering era due to its unique set of properties and wide application usage. It constitutes of variety of grades which are classified based on properties, cost. In this article, our primary f

Jun 17,2024

Jun 17,2024

A2-70 Stainless Steel vs 18-8: Choosing the Right Material

Marine grade A2-70 stainless steel is best for applications where high tensile strength is required. 18-8 stainless steel has high corrosion resistance and is used in applications where ease of fabrication and cost are the priorities. In this article, you

Jun 17,2024

Jun 17,2024

409 Stainless Steel: A Comprehensive Guide for Engineers and Designers

Stainless steel is one of the most durable and versatile materials known for its wider range of application in modern manufacturing era. It comprises of different grades, each with its own properties and characteristics. This article will primarily focus

Jun 17,2024

Jun 17,2024

52100 Stainless Steel: A Comprehensive Guide for Engineers and Designers

52100 is a high carbon steel. it contains significant amount of chromium which enhances its corrosion and mechanical properties. That is why it has become a popular choice in different industries. AISI 52100 stainless steel serves best in high loading con

Jun 14,2024

Jun 14,2024

What is the Density of Copper? Calculation and Uses

Copper is a fundamental material in many industries. It is known for its excellent electrical conductivity. It is also valued for its thermal conductivity. Additionally, copper is highly malleable. The density of copper is approximately 8.96 grams per cub

Oct 15,2024

Oct 15,2024

Melting Point of Aluminum: A Complete Guide

Aluminum is widely used in many industries because it is lightweight and versatile. One key aspect of aluminum is its melting point. This affects how it is processed and used in manufacturing. This article explores the melting point of aluminum. It also c

Oct 11,2024

Oct 11,2024

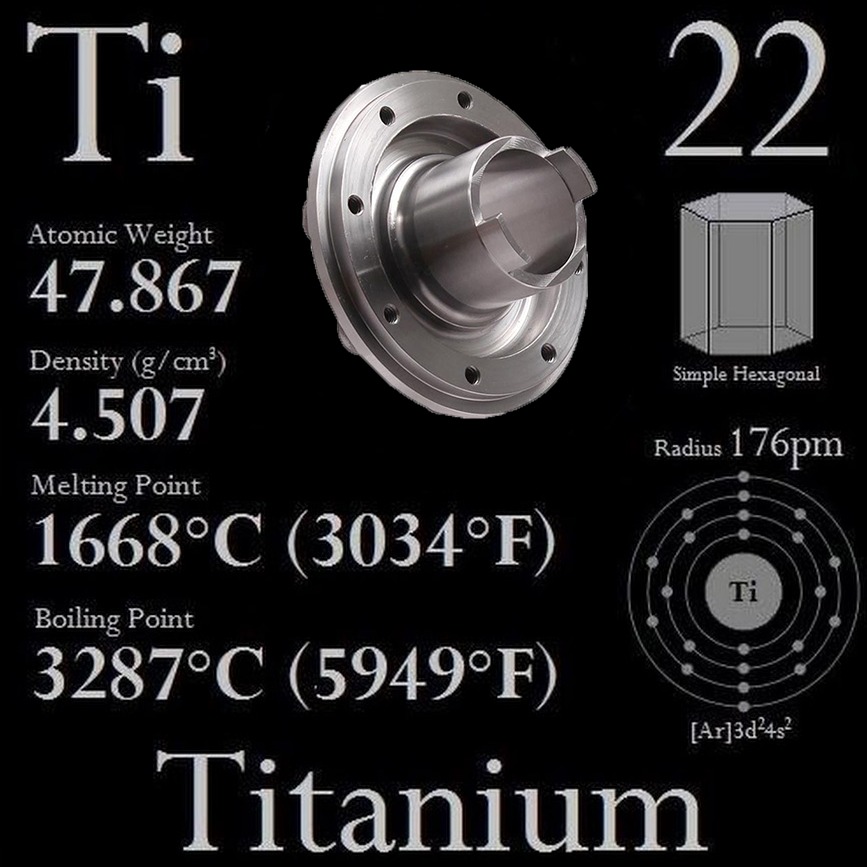

Density of Titanium: Specific Gravity and Atomic Structure

Titanium is a silvery-gray metal with the symbol Ti and atomic number 22. It is renowned for its exceptional properties. These include a high strength-to-weight ratio and excellent corrosion resistance. Understanding the density of titanium is crucial. It

Oct 15,2024

Oct 15,2024

What is the Melting Point of Brass?

Brass is a widely used alloy primarily composed of copper and zinc. Brass is known for its good looks, strength, and easy machining. It is used in plumbing, electrical work, musical instruments, and decorations. Knowing the melting point of brass is key f

Jun 05,2024

Jun 05,2024

What is the Melting Point of Copper?

The melting point of copper is a crucial property. It influences copper's utility in various applications. As professionals in the manufacturing industry, understanding this fundamental characteristic is essential. It can enhance our processes and pro

Jun 05,2024

Jun 05,2024

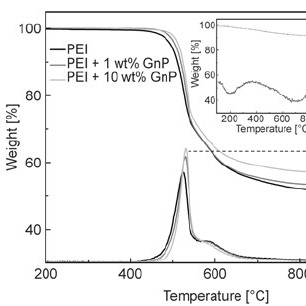

Exploring Ultem 1000: A Comprehensive Guide

Ultem 1000 is a polyetherimide PEI which is high performance material fall in the category of thermoplastic materials. Polyetherimide PEI is well known for its inherent flame retardation, dielectric strength, mechanical strength, and stiffness that's

Jun 01,2024

Jun 01,2024

What is the Melting Point of Titanium?

By understanding them, you will see why people prefer titanium. Industries such as aerospace, medical, and manufacturing use it. Its melting point impacts its use in many industries. It has a high melting point. This, combined with its other unique proper

May 31,2024

May 31,2024

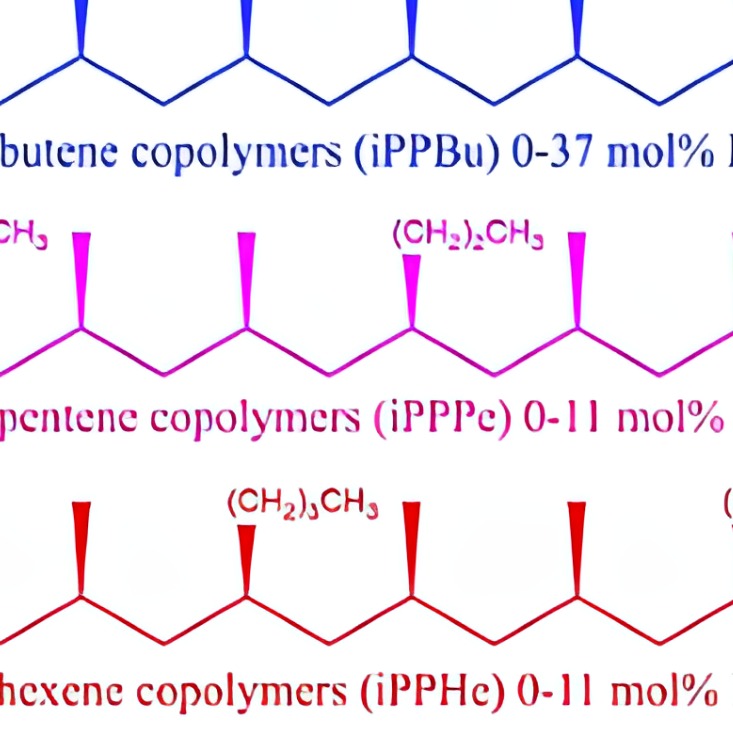

Types, Properties, and Applications of PP Copolymer: A Comprehensive Guide

The carbon polymer chain having hexane, ethylene, and butene substitutional groups is called polypropylene which is a thermoplastic polymer. Polypropylene copolymer is an industrial plastic used in a wide range of applications. Commodity plastics copolyme

May 29,2024

May 29,2024

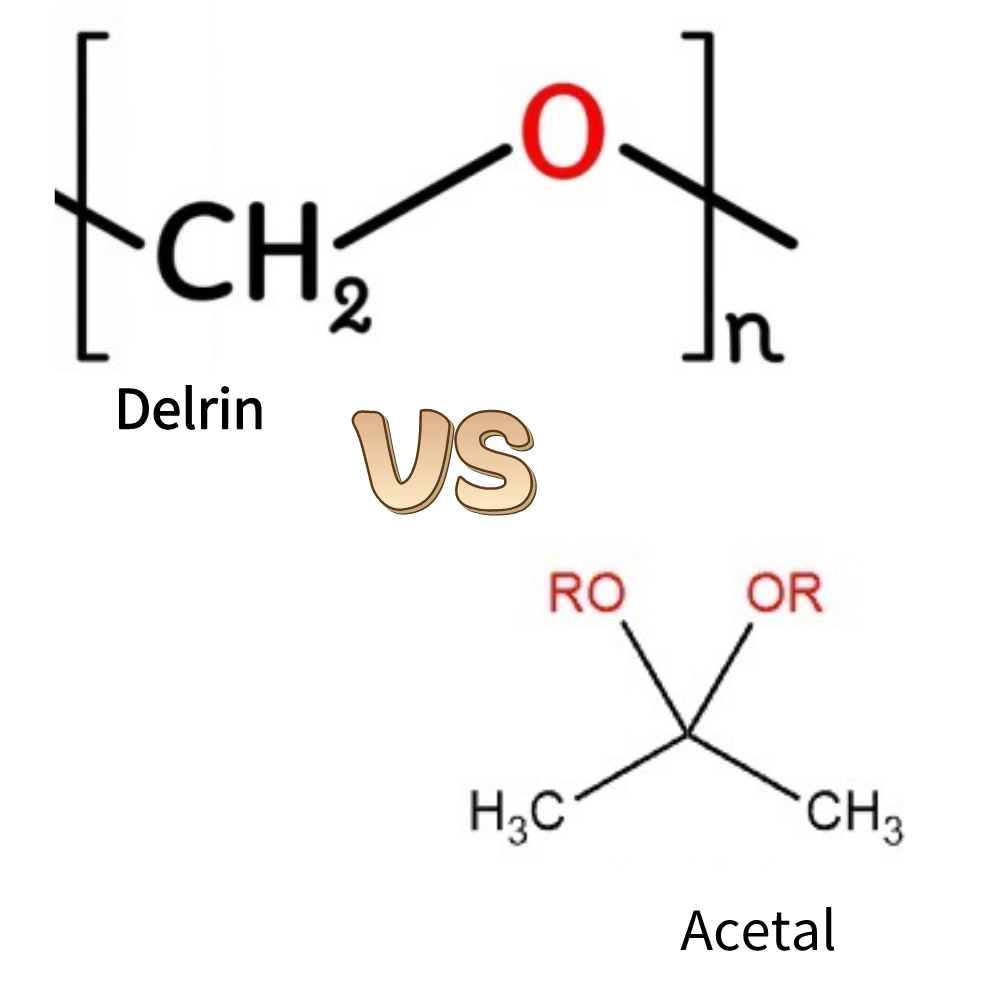

Acetal vs Delrin: A Comprehensive Comparison for Manufacturing and Mechanical Design

Polyoxymethylene, also named Acetal copolymer, is a thermoplastic which has semi-crystalline nature. Acetal copolymer has excellent dimensional stability, durability, and high friction. Acetal homopolymer known as Delrin has exceptional stiffness, strengt

May 29,2024

May 29,2024

Stainless Steel Melting Point: An Essential Guide for Mechanical Engineers

Stainless steel has a range of composition depending on the demands. Based on microstructures, these are like austenitic grades (316, 304), ferritic grades (430, 434) and martensitic grades (410, 420). Similarly, they can be categorized as alloying elemen

May 29,2024

May 29,2024

Understanding Metal Melting Points: A Comprehensive Guide for Manufacturing Professionals

This article will highlight the importance of metal melting points in manufacturing processes. The lowest melting point in metals is mercury which is -38 degrees Celsius. The highest melting point is of tungsten which is 3422 degrees Celsius. This shows t

May 13,2024

May 13,2024

15 Things You Didn't Know About Brass Alloy

Brass, a distinct and versatile metal alloy primarily composed of copper and zinc, has played a pivotal role in manufacturing and technological advancements across numerous industries. Its unique properties, including superb malleability, corrosion resist

May 10,2024

May 10,2024

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address