Bolt vs Nut: A Global Standard Comparison (ISO, DIN, ASTM)

Mar 17,2025

Mar 17,2025

Different standard organizations have established bolt and nut grades to identify the strength and material of fasteners. Grades play an important role when selecting bolts and nuts for any project. In simple words, these grades determine the level of stress they can handle. Each grade has its own specification, applications and it is important to know the difference among these grades to select right fasteners for any project.

How Do You Identify Nuts and Bolts?

The easy way to identify nuts and bolts is to look for markings on the head. This indicates their grade (strength) and type (metric or standard). The metric bolts often have numbers (e.g., 8.8) and standard bolts have lines or dashes.

What Are Bolts and Nuts?

Nuts and bolts are fasteners to attach pieces with each other. These are commonly used in manufacturing, construction, automotive and aerospace fields.

Definition of Bolts and Nuts

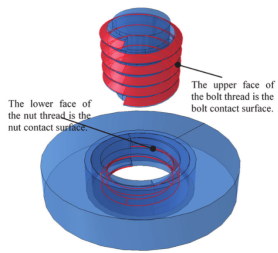

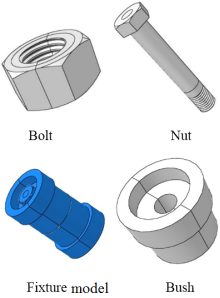

Nuts have internal threads and are normally hexagonal in shape. These are screwed onto the threaded end of bolt. Nuts have different types like cap nuts, expansion nuts and u-nuts.

Bolts have external threads and have a head at one end. These can be hexagonal or square in shape. These can be secured with nut onto a tapped hole. The types of bolts are eye bolts, hex bolt, u bolt, wheel bolts and machine bolts.

Bolt vs Screw

Screws are often used for precision fastening. Different types of bolts like hex bolt or u bolt are used in manufacturing and construction. Bolts are stronger, easier to assemble and disassemble and have better clamping power. Screws are tapered and make their own threads while bolts are not. Bolts are also costly than screws

Bolt Vs Nut Vs Washer

Bolts and nuts are threaded fasteners. These are used together to join objects. Bolts have heads and a cylindrical body, and screws have thread along its length.

Washers are used for load distribution. They prevent damage and minimize friction at the joining point. Washers help to prevent loosening and crushing.

The Role of Bolts and Nuts in Industrial Applications

Bolts and nuts secure components and ensure stability. For example, Hex bolts are used in engines, U-bolts used in connecting parts and flange nuts have built-in washer which distribute clamping force over the area.

Why Global Standards Matter for Bolts and Nuts

Global standards are essential to ensure efficiency, safety and efficiency for bolts and nuts in international projects and manufacturing. They standardize the dimensions, materials, and performance which helps to minimize errors and in global trading.

ISO, DIN, and ASTM Standards for Bolts and Nuts

ISO focuses on internation standards, ASTM on American and DIN on German standards. These all ensure safety, quality and computability of bolts and nuts.

What are ISO Standards for Bolts and Nuts?

ISO standards for bolts and nuts determine properties, dimensions and testing procedures to attain compatibility and reliability. Key standards are ISO-888 for lengths and threads length, ISO898-1 for carbon and alloy steel and ISO-898-2 for stainless steel fasteners

DIN Standards vs. ISO: Key Differences

ISO standard aims for global applications and helps in international trading and cooperation. While DIN is developed by German institute for Standardization (DIN) and focused on German national needs and practices.

Historical Development of DIN and ISO Standards

DIN was founded in 1917 originally as "Normenausschuss der Deutschen Industrie (NADI)" then later evolve into DIN Deutsches Institut für Normung e.V.(German Institute for Standardization) in 1975. It was developed for technical standards for engineering industries and other fields.

While ISO founded in 1947 with the joint coordination of 26 countries. It was developed to standardize technical rules and to simplify the exchange of goods and removing trade barriers globally

The Impact of DIN Standards on European Manufacturing

DIN standards significantly impact European manufacturing by improving quality, safety, reliability and consistency, improved interoperability, innovation and development, minimized costs, facilitated trade and lowered entry barriers to a particular market.

ASTM Standards: Focus on U.S. Manufacturing

ASTM standards had a great impact on U.S. manufacturing by improving efficiency and quality across different industries like consumer products, construction, manufacturing and material sciences. It helped in global trade, innovation and development, supported infrastructure projects and strengthened supply chain

How to Choose Between ISO, DIN, and ASTM for Your Project

To clear the difference between ISO, DIN and ASTM, the main points are discussed in the table below:

|

Features |

ISO |

DIN |

ASTM |

|

Scope |

Develops international standards for products quality, safety, and efficiency.

|

German institute develops standards for Germany.

|

develops standards primarily for the United States, but also for globally.

|

|

Focus |

adopted globally to facilitate international trade and ensure compatibility |

used as the basis for ISO standards but also have unique standards for German industries.

|

focus on material testing and performance criteria.

|

|

Regional focus |

Global |

Germany |

America |

Thread Standards for Bolts and Nuts: Global View

ISO metric threads often recognized as ISO metric (DIN) are used for screw threads standards globally. For example, ISO 261 and ISO 262 are served as foundations for general-purpose metric thread.

Coarse vs Fine Threads: ISO, DIN, and ASTM Comparisons

Corase threads have wider pitch than fine threads. Fine threads have smaller pitch and have more threads/in or mm. ISO and DIN specify threads pitch for different applications.

What Is Coarse Thread?

Coarse threads have a larger distance between threads. This implies it has fewer threads/in. or mm. it is suitable for applications where grip and resistance to stripping are required.

What Is Fine Thread?

Fine threads have a higher number of threads because threads are close to each other and pitch is smaller than coarse threads.

ISO VS DIN VS ASTM: Complete Comparisons

A brief comparison between fine and coarse threads standards like ISO, DIN and ASTM is written below:

|

ISO |

DIN |

ASTM |

|

Covers metric coarse and fine threads with pitch specification in mm |

German standard, serves as a basis of ISO standard with slightly different dimensions |

Uses inch and metric fasteners with threads specified by threads per inch (TPI) |

|

ISO 4032: Hex nuts with a coarse thread. ISO 8673: Hex nuts with a fine thread. |

DIN 934: Hex nuts (4032). DIN 912: Socket head cap screws (ISO 4762). |

Unified National Coarse Thread (UNC) Unified National Fine Thread (UNF) |

Thread Pitch and Diameter: A Comparison Across Standards

ISO designates threads as ‘M" and use metric units (mm) followed by diameter and pitch (e.g., M6x1). ASTM designates threads by threads per inch (TPI) and uses imperial units (inches). DIN standard is based on ISO with slightly different dimensions for fine threads.

How to Measure Thread Pitch in Different Standards

ISO and DIN used millimeter units for thread pitch or distance between threads. And ASTM uses threads per inch (TPI)

Measuring Thread Tolerances in Bolts and Nuts

Threads tolerance in bolts and nuts is measured by determining the difference largest outer diameter, midpoint pitch diameter, and pitch by using calipers, gauges or rules

Material Considerations: Bolts and Nuts Across Standards

Material selection for bolts and nuts require some consideration such as environmental condition of applications, strength, load requirements and some common materials are steel, stainless steel, and various alloys.

Material Properties in ISO, DIN, and ASTM Standards

These standards define material properties for bolt and nuts such as tensile strength, yield strength, elongation and hardness. ISO 898-1 for carbon alloys and ISO3506-1 for stainless steel, ASTM-A194 for carbon and alloys steel and ASTM-A563 for wrought metals. DIN is based on ISO with a slight difference.

How Material Specifications Impact Bolt and Nut Performance

Material specification can have a great effect on bolt and nut performance by affecting their corrosion resistance, strength, hardness and elongation and suitability for specific applications.

Choosing Materials Based on Strength Requirements

Material selection for bolts and nuts based on strength requirements considers factors such as resistance properties, working temperature, load, stress and strength with commonly used materials like stainless steel, aluminum, titanium or brass.

Bolt and Nut Sizes: Global Standards for Sizing

Bolt and nuts sizes follow either ISO or imperial system globally with bolt diameter and thread pitch and nuts matching the corresponding bolt's size.

Measuring Bolt and Nut Sizes According to ISO

According to ISO, bolt and nut sizes are measured by determining nominal diameter "M" and pitch "P" in millimeter. It is normally expressed as "M[diameter] x [pitch]"(e.g., M8 x 1.25)

DIN and ASTM Size Guidelines and Conversion

DIN and ASTM standards can be different in specific dimensions and tolerance. DIN measures distance from one thread to the next pitch in millimeters while ASTM measures the number of threads in one inch. A DIN-M12 in ASTM standard is equivalent to 7/16-inch ASTM bolt.

How to Convert Bolt Sizes Between ISO and DIN

A reference chart is used to convert the bolt size into different standards. Some examples of the standards for bolt and nuts are written below:

|

Design |

ISO |

DIN |

|

Hex Head Bolt, Partial Thread |

4014 |

931 |

|

Hex Head Bolt, Full Thread |

4017 |

933 |

|

Hex Head Bolt, Fine Thread |

8765, 8676 |

960,961 |

|

Thin Hex Nut |

4035, 4036 |

439 |

|

Hex Nut |

4032 (Coarse Thread), 8673 (Fine Thread) |

934 |

|

Socket Head Cap Screw, Coarse Thread |

4762 |

912 |

|

Socket Head Cap Screw, Fine Thread |

12474 |

912 |

Converting Metric Sizes to Imperial Sizes

Metric size (mm) nut and bolt size can be converted to imperial (in.) by dividing the metric diameter by 25.4 to get the equivalent inch diameter

How to Choose the Right Size Based on Your Application

To select the right size of nut and bolt, consider some factors like load requirements, material thickness and clamping forces. Bolt diameter and length are matched to the thickness of joining material. This will ensure sufficient thread engagement and grade for the strength required.

Surface Treatments and Coatings for Bolts and Nuts

Surface treatments and coating enhance corrosion resistance, durability and aesthetics of bolt and nuts.

Corrosion Resistance and Surface Treatments

To enhance corrosion resistance of bolt and nuts, coating and surface treatment are done like zinc plating, hot-dip galvanizing, chromium plating, and specialized coating Xylan, and cadmium plating.

Surface Finish Requirements in ISO, DIN, and ASTM

ISO-4042 for threaded fasteners, ISO-9227 for measuring corrosion resistance, ISO-10683 for zinc coating, ISO-898-1 for carbon steel and alloy steel fasteners and ISO-3506-1 for stainless steel corrosion resistance. DIN-7346 for light-duty toll pins, ASTM-B117 for corrosion resistance, ASTM-B633 for zinc coating, ASTM-A194 for carbon and alloy steel nuts and bolt.

Common Surface Coatings: Zinc Plating vs. Galvanizing

Galvanizing has a thicker and durable zinc coating applied by sinking steel in molten zinc. While zinc plating is an electrolytic process for thinner and cost-effective coating.

National Standards: GB and JIS for Bolts and Nuts

GB and JIS are standard for China and Japan respectively which also specify dimensions, tolerance and material for fasteners

GB Standards for Bolts and Nuts (China)

GB stands for Guobiao Standards is China's national standards. "GB" indicates mandatory standards and "GB/T" for recommended standards. These specify standards for product testing and certification for nuts and bolts such as GB/T 5782.

JIS Standards for Bolts and Nuts (Japan)

Japanese Industrial Standards (JIS) for bolts and nuts such as JIS-B-1180 for hexagon head bolts and screws, and JIS-B -186 for high-strength bolts and nuts.

How GB and JIS Standards Differ from ISO, DIN, and ASTM

ISO is an international standard while GB, JIS, DIN and ASTM are national standards for China, Japan, Germany and USA, respectively. GB and JIS are differ to ISO, Din and ASTM in terms of material properties, tolerance and dimensions.

GB and JIS follow ISO metric, for example, JIS-B0203 for tapered pipe thread and JIS-B0202 for parallel pipe threads, GB/T-712 for yield strength, GB/T-700 for structural steel, JIS-G3101 for common steel structures, Q235 and A345 for various steel grades and SS400 for Japanese steel grades.

How to Choose the Right Bolt and Nut Suppliers for Your Project

There are some factors that need to be considered when selecting the right bolt and nut suppliers and these are discussed below:

Factors to Consider When Choosing Bolt and Nut Suppliers

The factors are explained below for supplier selection of nuts and bolts.

Understanding Application-Specific Requirements

Firstly, understand application requirements such as thread compatibility, load and stress requirements, and environmental conditions that suit the material like corrosion and wear resistance.

Choosing Suppliers Based on Standards

It is very important to know the focus of their adherence to industrial standards like ISO or DIN and certificates like ISO 9001 and their ability to provide reliable service and quality products.

Regional Considerations: Outsourcing to Different Countries

If you are selecting suppliers from different countries, there are some factors to consider:

Working with Suppliers from Different Countries

It requires careful planning and focus to have clear communication. It also requires cultural awareness, building trust and understanding challenges like language barriers and time differences

Cross-Border VS Local Shop

Cross border is purchasing material from different countries while local shops are within the same country. If consider China from cross-border allows broader market access to lower over-head.

Conclusion:

Nuts and bolts are fasteners to attach objects to each other. Different types of bolts like hex bolt or u bolt are used in manufacturing and construction.Global standards such as DIN, ASTM standards or ISO for fastener types also help to reduce costs, ensure quality. They enhance reliability and efficiency in operations in various sectors, from construction, manufacturing to automotive and aerospace. It also improved material development and characterization, additive manufacturing and promoted sustainability.

FAQ

Do all bolts need a nut?

No, all bolts do not need nuts. Some require screws or lag bolts

Which thread type should I use for my bolts and nuts?

Use bolt and nuts that matches thread type, consider bolt grade and appropriate tool like wrench or socket size and relevant standard when selecting thread.

How do I convert bolt sizes between different standards?

use a conversion chart to find equivalent sizes, focusing on diameter, thread pitch, and length to convert bolt size between different standards.

What is the difference between a bolt and a nut?

A bolt is a threaded fastener with an external thread and a head and nut is a small metal block with an internal thread.

Bolt vs screw, what's the main difference?

Bolt needs nuts to be secured, and screws create their own threads and have no need for separate nuts.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Coarse Thread vs. Fine Thread: From Design to Manufacturing

Coarse Thread vs. Fine Thread: From Design to Manufacturing