S35VN Steel: Why It is a Top Choice for Knives

Aug 24,2024

Aug 24,2024

S35VN Steel is famous for its toughness and wear resistance. This is due to a combination of unique elements in alloy composition which makes it an outstanding knife steel with high cutting performance. This high carbon steel is suitable for many indoor and outdoor applications and is the right choice for camping and entertainment trips and tours. Further information about the blade material, cutting performance due to its alloy composition and pros and cons with applications are discussed below.

What is S35VN Steel

S35VN steel is a high carbon steel with premium corrosion resistance and toughness. It also has excellent edge sharpness and retention, which is ideal for high cutting performance knives. S35VN is a top pick for a variety of purposes like kitchen knives, or blade material for outdoor use and as survival knives.

Is S35VN a Super Steel

S35VN is high quality steel. It is known for its edge sharpness, toughness and corrosion resistance. It could not be considered as super steel but its knife performance and other features are comparable to other super steels like K390 and CPM3V.

What is Crucible Particle Metallurgy?

Crucible particle metallurgy or CPM is a commercial production process. It is utilized for high-speed steels and high alloy composition tool steels. This process produces higher quality tool steel than conventional steel production methods. It involves an atomization melting process of alloys. This creates small droplets of molten metal which can be cooled down rapidly and form a fine grain size structure which has premium mechanical properties and other features.

How CPM Enhances S35VN Steel Quality

CPM method creates homogeneity in microstructure. CPM steels are characterized by high dimensional stability, toughness and grinding features than other steels made by conventional methods. CPM S35VN steel has a martensitic structure which provides high-end toughness. The machinability and polishing are easier and has balanced chemistry between alloy composition. The presence of carbides in microstructure increases wear resistance and has better edge sharpness.

What is S35VN Steel Equivalent To?

S35VN Steel is like S30V in terms of alloy composition like C or Cr. It has the same edge sharpness and corrosion resistance. However, comparing its toughness S30V and other comparable grades like Elmax or S45VN have less toughness than S35VN. In terms of hardness, Vanax is like S35VN, but Vanax has better corrosion resistance. overall, S35VN is more suitable for outdoor applications and moist areas.

S35VN Steel Chemical Composition

S35VN steel chemical composition has elements like niobium and vanadium. These elements when combined with carbon, increase the toughness of steel. furthermore, S35VN steel has balance of hardness and toughness which makes it a high-quality steel.

Carbon Content

C is the important element for improved hardness in steels. Only C can increase hardness up to 65HRC. The higher the carbon, the higher the hardness in the knife. When it combines with other elements like Cr, Mo and V, they create carbide. This further improves the hardness in alloy.

Chromium Content

Cr is the main element in steel. this the reason of corrosion resistance in steels. It further improves the strength when creating carbides. This results in increasing wear resistance.

Molybdenum Content

Mo increases toughness in steel. This is an important element as increases the hardness. But it simultaneously increases the brittleness in steel. When this is combined with carbon, creates carbides and increases wear resistance up to 75HRC.

Vanadium Content

V increases toughness and strength in steel. it helps in creating fine grain size in microstructure. V when combined with carbon, it creates carbides which increases edge sharpness and hardness up to 84HRC.

Chemical Composition Data Sheet

|

Elements |

Percentage |

|

Carbon |

1.4% |

|

Cr |

14% |

|

Mo |

2% |

|

Nb |

0.50% |

|

V |

3% |

|

Fe |

79.1% |

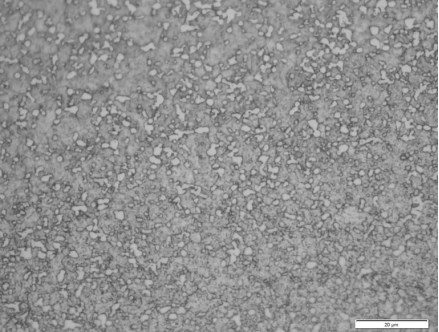

Microstructure of S35VN steel

S35VN has homogeneous fine grain size structure due to CPM method. This type of microstructure is responsible for high wear resistance, and edge sharpness. But it has less carbides than its predecessor S30V. Because it has lesser Vanadium and Niobium. MC content is 3.5% in S35VN while S30 has 4%. MC is the hardest carbide which improves wear resistance. Its presence slightly makes the grinding, machining, and polishing difficult. When using softer abrasives like alumina, it gives poor results.

S35VN Microstructure and Its Impact on Performance

The presence of Cr, Nb and V in microstructure creates balanced chemistry of carbides. These carbides are responsible for toughness in S35Vn without compromising wear resistance. S35VN also has better edge sharpness, hardness and chromium carbides makes wear resistance better. This is why it is preferred blade material than other conventional steel blades.

S35VN Steel Mechanical Properties

|

Mechanical properties |

Values |

Comments |

|

Density |

7.47g/cm3 |

|

|

Hardness |

56.6HRC |

Austenitizing 1900°F/ tempering1000°F/freezing |

|

69HRC |

Austenitizing at 1900°F/ quenching |

|

|

64HRC |

austenitized at 2000°F, oil quenched + freeze |

|

|

57HRC @Tempering Temp. 1000 °F |

Austenitizing at 1900°F/ quenching/ tempering |

|

|

57.5HRC @Tempering Temp. 600 °F |

Austenitizing at 1900°F/ quenching/ tempering |

|

|

57.5HRC @Tempering Temp. 400 °F |

Austenitizing at 1900°F/ quenching/ tempering |

|

|

Elastic modulus |

221GPa |

|

|

Charpy test |

16.3J |

Transverse V-notch test |

|

Coefficient of linear expansion |

11 µm/m-°C |

|

|

Thermal conductivity |

11.5 µm/m-°C |

|

Welding and Machining Techniques for S35VN Steel

Machining S35VN

S35VNcan easily be machined in its annealed conditions. this makes it a good for CNC machining and creates better CNC machining knife. It can also make intricate designs and precision designs which is essential for CNC machining knife.

Welding Challenges

Work hardening can occur during welding, drilling or cutting of S35VN steel. This can make the operation difficult to proceed. Heat input is essential to manage during the operation to achieve optimum results.

Other than these challenges, S35VN gives high cutting performance CNC machining knife which has balanced hardness, toughness, edge sharpness and corrosion resistance.

Pros and Cons of S35VN Steel

S35VN steel has many advantages but also has a few limitations. This topic will cover all the pros and cons of S35Vn steel.

S35VN Advantages

1. High toughness

Toughness can be identified by the ability to chips, crack, and all the damage resistance upon impacting. These damages are difficult to fix. And permanent damage can reduce the life of blade material. CPM S35VN has higher toughness than other steels. Niobium carbides are 30% than other high cutting performance steels like S30V. it also has better wear resistance, chip and crack resistance.

2. Easier machinability

CPM S35VN knife steel is preferred by craftsman. It is easy to machine, grind, drill and polish. Machinability in knife steel can be determined by the ability to ease in cut and can retain good finishing. S35Vn has high cutting performance, and high-quality blade material increases knife performance.

3. longer service life and high performance

This high carbon steel has the ability to withstand wear and tear without reducing its life. The quality of this knife steel does not get effected by any wear. After heat treatment, the blade material quality also gets improved and has better hardness in the range of 58-61HRC. A very hard steel has hardness in the range of 55-66HRC. Therefore, this range of hardness of S35VN knife steel makes it an excellent choice for a blade material. This type of knife with higher edge sharpness can be utilized in everyday use, outdoor use and for survival purposes. Except all these features, the service of knife steel is prolonged and without reducing its cutting performance and knife performance with the passage of time.

S35VN Disadvantages

The limitations in the applications of S35VN knife steel are as:

1. Costly than other conventional steel

S35VN CNC machining knife is more expensive than other knife steel. This is due to high quality knife steel, and blade material, high cutting performance. Knife performance. The alloy composition is also unique and contains all the expensive elements. The medium range steel has 3-4 times less cost than a CPM steel. when the CPM steels are undergoing further operations like machining, and heat treatment makes it even more expensive.

the rough estimate of S35VN knife steel is $100-300 while a medium steel can cost up to $50.

2.Requires additional processing for edge sharpness

CPM S35Vn has high edge sharpness but it can improve up to premium quality edge retention. This includes additional process and labor and skilled staff. This edge sharpness is preferred by hunters and for outdoor activities. This blade material has high corrosion resistance and toughness. These types of knife steel can be used in all the types of weather conditions and environments. Manufactures claims that CPM S35VN steel are more durable than other steels. But this extra hardness requires special hardness equipment and expert handling.

Is S35VN Steel Good for Knives

S35VN knife steel is known for its high cutting performance. This has a good combination of edge sharpness and high-end knife performance. The toughness, corrosion resistance and wear resistance are outstanding, which makes it useful for kitchen and outdoor activities. However, it is not labelled as “super steel”, but its properties and cost are comparable to all the high-quality steels.

Knife Types Suited for S35VN

S35VN has higher toughness than other knife steels. The best suited types of knives are larger knives like hunting knife, survival knife and tactical knife.

Featured Products Using S35VN Steel

High cutting performance knives:

S35VN is a high-quality knives and blade material. it has excellent toughness and corrosion resistance which is suitable for survival knifes

Tactical Folding Knife

Tactical folding knives are mostly made of S35VN knife steel. It has more durable design and perfect for camping and hunting purposes.

Heat Treatment of S35VN Steel

Heat treatment recommended for S35VN is austenitizing at temperature up to 1100°C. This is followed by quenching to 125°F. This improves the hardness in steel. recommended tempering method for S35VN is for 2hrs at 600°F twice for optimal results. This decreases the stresses and improves toughness.

S35VN Heat Treatment Recommendations

For better heat treatment results, a cryogenic liquid nitrogen treatment is suggested followed by quenching. This can refine the microstructure of steel.

Hardening Response

Austenitizing and tempering followed by quenching can increase the hardness up to 60HRC in S35VN knife steel.

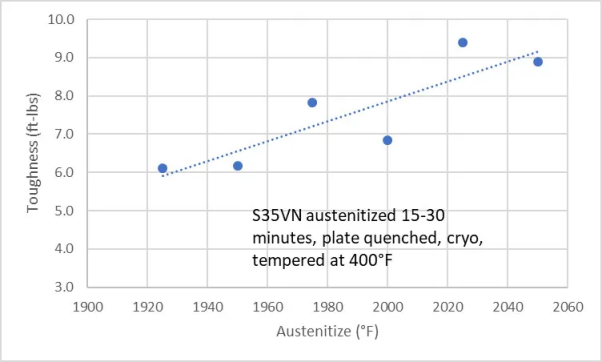

Toughness Optimization During Heat Treatment

Toughness can be optimized in S35VN steel by controlling the austenitizing and tempering temperatures. freezing procedures can increase toughness and hardness in S35VN knife steel.

S35VN Steel Alloy Comparison with Other Steels

S35VN Steel vs. D2

S35VN and D2 steel are high quality materials. But D2 is known as tool steel while the S35VN is more of a knife steel. S35VN is also a stainless-steel type which has higher corrosion resistance and rust prevention abilities than D2.

S35VN Steel vs. MagnaCut

Magnacut has high edge sharpness as compared to S35VN. It requires less sharpness method and high cutting performance. Corrosion resistance is also noted to be better in Magnacut and is durable for outdoor applications. Hardness and resistance to edge deformation is also higher in magnacut.

What Steel is Better: S35VN or S30V?

S35VN has high toughness and edge sharpness than S30. The toughness recorded to be 20% higher in S35VN due to presence of Niobium. This can also withstand high stresses and has more resistance to chipping and failure.

Is S35VN Better Than 154CM?

S35VN knife steel is better in toughness and wear resistance than 154CM. it has higher durability and edge sharpness. 154CM edge sharpness is also good but S35VN can hold edge longer because of fine grain size, and carbides presence. This contributes to overall knife performance of steel. S35VN has high corrosion resistance and is more suitable for outdoor applications and moist areas.

420hc vs S35VN Steel

420HC is famous for its high toughness. It is a more reliable option than S35VN in terms of durability. S35VN has high edge sharpness and is better high-quality knife steel. it has easy maintenance than 420HC. Both steels have good corrosion resistance. but in some case, it has better corrosion resistance for outdoor applications.

Elmax vs S35VN

S35VN has better wear resistance and corrosion resistance. Elmax has less Cr content. It also has ess hardness than S35VN. Edges of elmax can dull faster than S35VN but can be sharpened easily.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

A Comprehensive Guide to AISI 1045 Medium Carbon Steel

A Comprehensive Guide to AISI 1045 Medium Carbon Steel