6061-T6 Aluminum: The Engineers Guide

Aug 15,2024

Aug 15,2024

6061-T6 aluminum strength and light weight property make it different from other aluminum alloys. High strength to weight ratio of 6061-T6 Aluminum makes it ideal for aircraft applications. This article would help you to choose 6061-T6 Aluminum for desired application by understanding its properties and features.

What is 6061-T6 Aluminum?

6061-T6 Aluminum T6 shows tempering heat treatment is done on this alloy. 3.3214 t6 is high-strength and high-corrosion aluminum. 6061 t6 aircraft aluminum parts are well known for their strength and corrosion resistance [1].

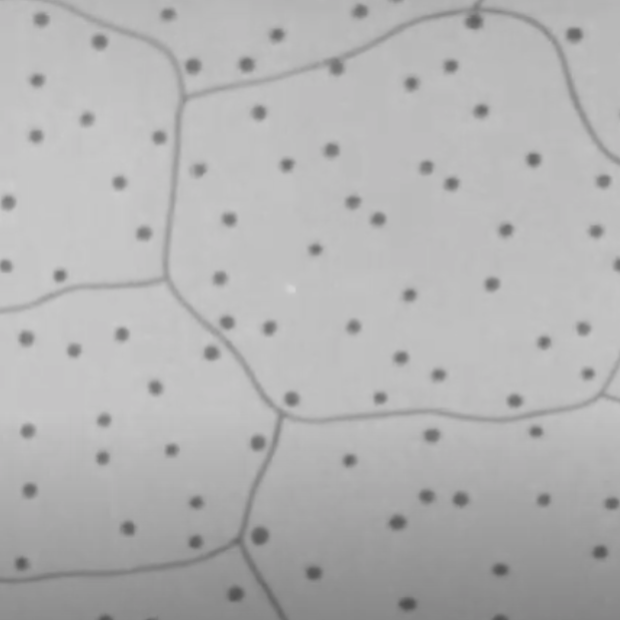

6061-T6 Heat Treatment

Heat treatment aluminum is reheated at a low temperature for a few hours and then room cooled slowly. This process reduces the quenching thermal stresses and mechanical stresses stored during machining.

Is 6061-T6 Heat-Treated Stronger than Steel?

6061-T6 Aluminum is not stronger than steel but it is lightweight due to which it is used in applications where weight to strength ratio matters.

Chemical Composition

The 3.3214 t6 Aluminum contains silicon, zinc, magnesium, copper, and titanium. These combinations of alloys and heat treatment make it high-strength aluminum and corrosion-resistant aluminum.

|

Element |

Percentage (%) |

|

Magnesium |

0.8 - 1.2 |

|

Silicon |

0.4 - 0.8 |

|

Copper |

0.15 - 0.40 |

|

Iron |

0.7 max |

|

Zinc |

0.25 max |

|

Chromium |

0.04 - 0.35 |

|

Titanium |

0.15 max |

|

Manganese |

0.15 max |

|

Aluminum |

Remainder |

Temper Designation T6

The T6 designation shows the tempering process. The tempering process removes the internal stresses of the material. Quenching and machining process cause development of internal stresses in material. Hardness increases cracking chances so tempering reduces hardness and improves ductility.

What Are the Equivalents of 6061-T6 Aluminum?

6061-T6 Aluminum designations include:

- AA6061-T6

- Alcoa 6061-T6

- ASTM B221

- EN AW-6061

- 3214 t6

Advantages and Disadvantages of Using 6061-T6 Aluminum

6061-T6 aluminum is lightweight, has high corrosion resistance, excellence strength and machining are easy. The disadvantages of aluminum are that it is costly and less strong than steel. Knowing these pros and cons helps in selecting the right material for the desired application [6].

6061-T6 Aluminum Forms: Sheet, Plate, Bar

Heat-treatable aluminum is available in different forms sheets, bars, and plates. These are raw forms of heat-treatable aluminum which is further processed to desired shapes according to your application.

- Sheet and Plates: These are used to make machinery components, construction, automotive and electrical parts.

- Bar: These are used to develop ladders, machinery parts, and fasteners.

6061 T6 Aluminum Cost

The cost of 3.3214 t6 aluminum is low compared to other aluminum alloys. Compared to properties of 3.3214 t6 aluminum the cost is low. The cost changes according to shape and size of material brought.

Physical Properties

Physical properties of 3214 t6 aluminum is studied to understand material features to select it for particular application.

Density

2.70 g/cm³ is the density of 3.3214 t6 aluminum.

Thermal expansion

Thermal Expansion of 6061-T6 Aluminum is 23.6 µm/m·°C.

Thermal Conductivity

ISO AlMg1SiCu thermal conductivity is 167 W/m·K.

Mechanical Properties of 6061-T6

The mechanical properties of 6061-T6 aluminum are very unique such as hardness, tensile strength, elongation shear modulus, etc. Knowing these properties helps in selecting the right material for the desired project.

Hardness

95 Brinell (HB) is the hardness value of ISO AlMg1SiCu.

Rockwell Hardness

B60 Rockwell hardness value of AA6061-T6 aluminum.

Tensile Strength

310 MPa is the tensile strength of EN AW-6061.

Yield Strength

276 MPa is the yield strength of Alcoa 6061-T6.

Elongation

12% for 2 inches is the elongation of ISO AlMg1SiCu.

Young's Modulus

68.9 GPa is the young’s modulus of ISO AlMg1SiCu.

Shear Modulus

The shear modulus has ISO AlMg1SiCu 26 GPa.

Fatigue Resistance

UNS A96061 has a fatigue resistance of 96.5 MPa.

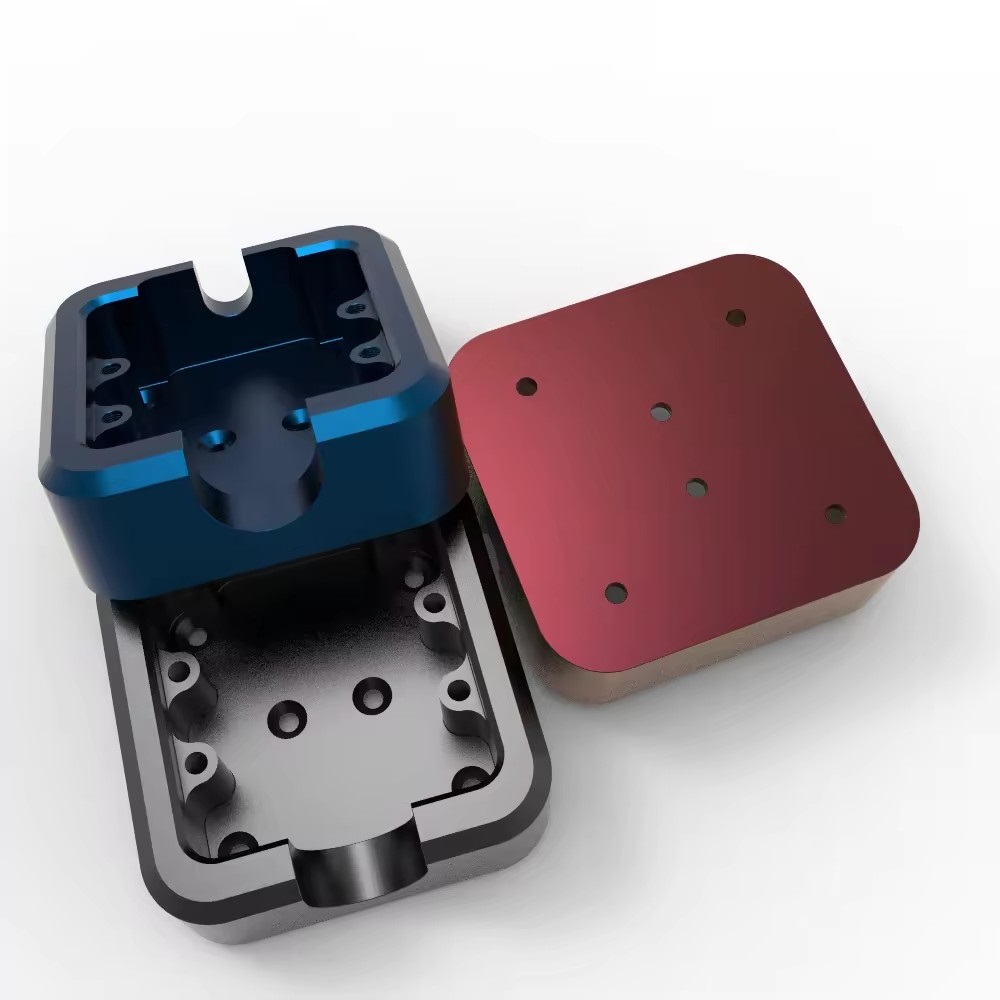

Machinability of AL Alloy 6061 T6

Heat-treatable aluminum 6061 T6 machinability is easy because has good toughness. Although 6061 T6 aluminum shows a smooth surface finish. CNC machining of 6061-T6 Aluminum can be done highly effectively by experts in Toufa. For further details see websites.

Can you Bend 6061 T651 Aluminum?

6061 T651 aluminum bending is done after heating otherwise cracks would be generated. The post-heat treatment would also be done to remove bending stresses.

Applications of 6061-T6 Aluminum: A Multi-Industry Powerhouse

6061-T6 Aluminum has many uses in automotive, marine, construction, and more.

|

Industry |

Applications |

|

Aerospace |

Structural components |

|

Automotive |

Car parts |

|

Construction |

Structural beams |

|

Electronics |

Heat sinks, electrical components |

|

Marine |

Boat frames, marine fittings |

|

Consumer Goods |

Bicycles, sports equipment |

Aluminum 6061 T6 vs Other Materials

6061-T6 Aluminum is compared to many other materials. Some of the comparisons are:

Differences in CNC Machined Parts: 6061-T6 vs. 5052-H32

Machinability

- 6061-T6: Easier to machine with CNC tools, allowing for more precise and efficient cutting.

- 5052-H32: Slightly harder to machine, which might result in slower processing times and more tool wear.

Surface Finish

- 6061-T6: Tends to yield a smoother surface finish after machining, requiring less post-processing.

- 5052-H32: May have a rougher finish post-machining, often requiring additional smoothing.

Dimensional Stability

- 6061-T6: Retains dimensional accuracy well during and after machining.

- 5052-H32: More prone to slight deformation during machining, especially with thinner parts.

Application Suitability

- 6061-T6: Best for parts requiring high strength, precision, and a fine finish.

- 5052-H32: More suitable for parts where corrosion resistance and flexibility are prioritized over high precision.

6061 T6 Aluminum vs 6063 T6

6063-T6 is less strong than 6061-T6 Aluminum but when it comes to appearance and aesthetics then 6063-T6 is preferred whereas, for strength purposes, 6061-T6 Aluminum is used.

Chinese Machining Services

Precision Engineering for Innovators

Send drawings to info@tuofa-cncmachining.com

Faster and Cheaper

6061 T6 Aluminum vs 7075

7075 Aluminum is stronger and more expensive than 6061-T6 Aluminum. For manufacturing airplane parts 7075 Aluminum is used because of its good strength property but for daily use 6061-T6 Aluminum is preferred.

7075 T6 vs 6061 T6

6061-T6 Aluminum is more corrosion resistant than 7075-T6 that why it is easier to work with because there is no issue of rusting. However, the tensile strength of 7075-T6 Aluminum is more than 6061-T6.

6061 T6 vs T4

6061-T4 is soft and flexible due to which it is useful for shaping and forming operations whereas, 6061-T6 Aluminum has high strength and is stronger than 6061-T4.

6063-T52 vs 6061-T6

6063- T52 has good surface properties that’s why it is preferred to be used in applications where high-quality finish matters. However, 6061-T6 Aluminum is used in projects where heavy-duty projects because of its high-strength properties.

2024 T3 vs 6061 T6

2024-T3 has good mechanical properties like strength and fatigue resistance but has poor corrosion resistance compared to 6061-T6 Aluminum. 6061-T6 shows good corrosion resistance with excellent strength and fatigue resistance.

6061 T5 vs 6061 T6

6061 T5 vs 6061 T6 both are same but the cooling method after aging is different. This aging method cause slightly different in mechanical properties due to which 6061-T6 Aluminum has more strength compared to 6061 T6.

When to Choose 6061-T6 Aluminum?

For aircraft applications 6061-T6 Aluminum is the best choice. 6061-T6 Aluminum shows ease of machining making it easy to form complex shapes from it. For applications where strength and fatigue resistance are the main concern 6061-T6 Aluminum is the ideal choice.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

T6 Temper Aluminum: A Comprehensive Guide for Engineers and Machinists

T6 Temper Aluminum: A Comprehensive Guide for Engineers and Machinists