6061 T6511 Aluminum: The Ultimate Guide

Aug 01,2024

Aug 01,2024

6061 T6511 Aluminum is used widely for engineering applications because of its precision machining. 6061 T6511 temper aluminum shows ease of fabrication, versatility, excellent corrosion, and mechanical properties. The amazing properties of heat-treated 6061 T6511 aluminum make it ideal for engineering components that need high durability and strength. The exploration of 6061 T6511 aluminum is done in this guide to highlight the applications, features, and benefits.

What is 6061-T6511 Aluminum?

Heat-treated alloy designated as 6061-T6511 aluminum where 6061 shows aluminum composition containing magnesium and silicon. T6511 is solution heat treated, stretched for stress releasing and artificially aging. These heat treatments cause improvement in mechanical properties, corrosion resistance, and machinability and enhance precision engineering applications.

Is 6061 T6511 Heat Treated?

Yes! 6061 T6511 Heat Treated with solution heat treatment, stress releasing by stretching, and artificial aging.

Chemical Composition

The chemical composition of T6 temper aluminum contains magnesium and silicon primarily with some trace elements given below in table.

|

Element |

Percentage (%) |

|

Aluminum (Al) |

95.8 - 98.6 |

|

Magnesium (Mg) |

0.8 - 1.2 |

|

Silicon (Si) |

0.4 - 0.8 |

|

Copper (Cu) |

0.15 - 0.4 |

|

Chromium (Cr) |

0.04 - 0.35 |

|

Iron (Fe) |

Up to 0.7 |

|

Manganese (Mn) |

Up to 0.15 |

|

Zinc (Zn) |

Up to 0.25 |

|

Titanium (Ti) |

Up to 0.15 |

|

Residuals |

Up to 0.15 |

6061 T6511 Aluminum Properties

The tensile strength of thermally treated T6 aluminum is 45000 psi, yield strength is 40,000 psi, shear strength is 30,000 psi, and hardness is 95. T6 temper aluminum shows excellent corrosion resistance in atmospheric and chlorine environments. TIG AND MIG are used to weld T6 temper which should be post heat treated to maintain strength and mechanical properties. This thermally treated aluminum allows showing good machinability in terms of shaping, cutting, and forming.

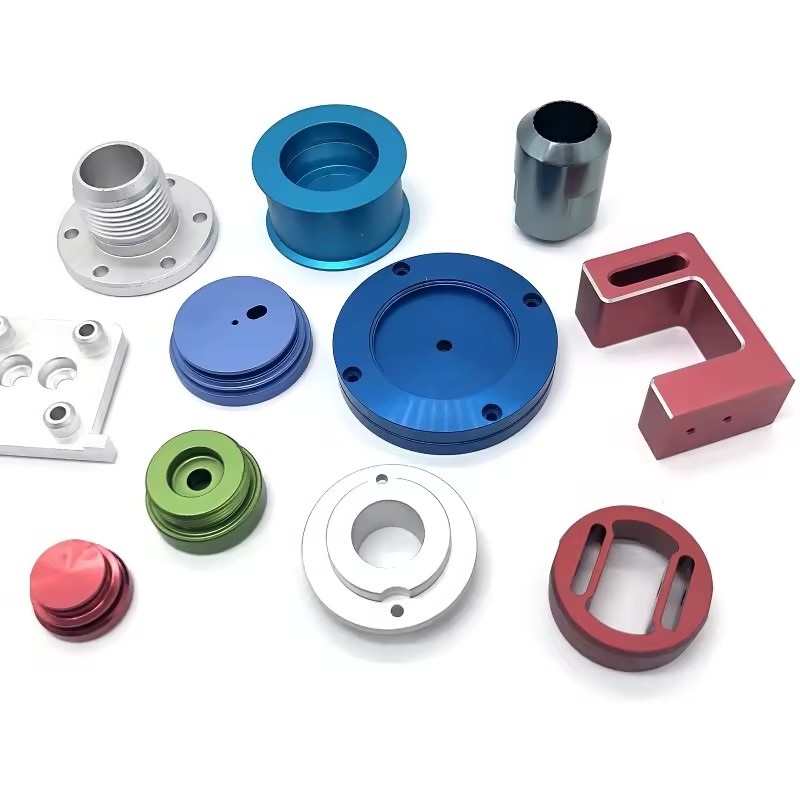

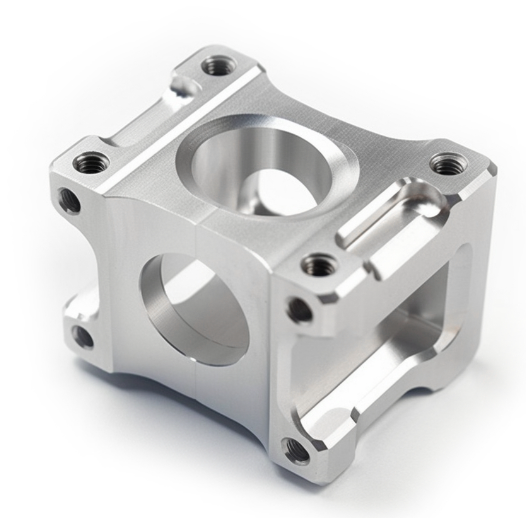

T6511 aluminum component.

T6511 temper heat treatment process

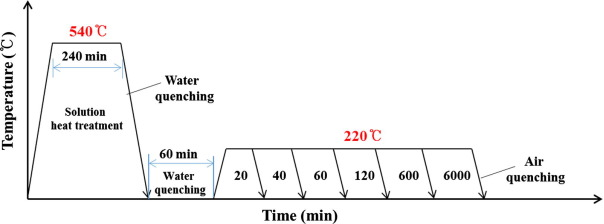

Temper Designation T6511: The heat treatment involves three steps which are discussed below. Also, the alloy's unique characteristics enhancement in every step is discussed.

Solution heat treatment: Homogeneity is achieved by dissolvement of magnesium and silicon. This will increase ductility, machinability, and forming of T6 temper. The T6 tempered aluminum is heated at 525°C and then quenched in water.

Stress-relieving steps: This step involves stress relieving where material is mechanically stretched to remove heating and quenching stress.

Artificial aging: The tempering of material is done in this step where material is heated at 180°C for several hours.

The heat treatment process of 6061 T6511 Aluminum is shown in the above schematic.

Specification: Certifications and Standards

ASTM B221 is used for rods and bars while ASTM B209 is used for plates and sheets.

6061 T6511 Aluminum Equivalent

Other designations of 6061 T6511 are EN AW-6061, ISO AlMg1SiCu, and AlMgSiCu.

6061-T6511 in Various Forms

Round Bar, Rectangular Bars, sheets, and plates are the initial forms of 6061-T6511 aluminum which are further machined to shape into a specific component.

Round Bar: This is widely available to be processed into bushings, pins, and shafts.

Rectangular Bar: This is converted to brackets, structural components, and frames.

Other Forms: 6061-T6511 aluminum is also present in the form of plates and sheets for different applications.

Sheets of 6061-T6511 aluminum.

Mechanical Properties of 6061-T6511

The comparison between different 6061 aluminum is done below which shows that 6061-T6511 aluminum shows better dimensional stability and strength compared to other 6061 aluminum alloys.

|

Property |

6061-T6511 |

6061-T6 |

6061-T651 |

|

Tensile Strength |

45,000 psi (310 MPa) |

45,000 - 47,000 psi (310 - 325 MPa) |

39,000 - 42,000 psi (270 - 290 MPa) |

|

Yield Strength |

40,000 psi (276 MPa) |

40,000 - 42,000 psi (276 - 290 MPa) |

35,000 - 39,000 psi (241 - 270 MPa) |

|

Elongation |

17% (minimum) |

8% (thickness < 0.25") |

10 - 12% |

|

|

|

10% (thickness > 0.25") |

|

|

Brinell Hardness |

95 |

95 |

95 |

|

Shear Strength |

30,000 psi (207 MPa) |

30,000 psi (207 MPa) |

30,000 psi (207 MPa) |

|

Modulus of Elasticity |

10,000 ksi (69 GPa) |

10,000 ksi (69 GPa) |

10,000 ksi (69 GPa) |

|

Dimensional Stability |

Highest |

Lower than T651 |

High |

Hardness and Fatigue Resistance

6061-T651 aluminum has gone through additional processes making it high strength, high hardness of 95 reducing the risk of wear, and improving surface finish also results in excellent fatigue resistance.

Stress Corrosion Cracking Resistance

6061-T651 aluminum after solution heat treatment and quenching in water is gone through an additional process of stress relieving by stretching. This process removes internal stresses and reduces the risk of stress corrosion cracking which is a common problem in aluminum.

Machinability of 6061-T6511

The 6061-T651 aluminum has gone through different heat treatment processes with an additional process of mechanical stretching which reduces the internal stresses of the material making it more ductile. This enhances ductility and also improves machinability.

Excellent Machinability

6061-T6511 aluminum is best for CNC machining and other manufacturing processes which are precise due to its excellent machinability property.

Benefits of Stress Relieving for Machining

The stress relieving by mechanical stretching reduces internal stretches which are the cause of distortion and warping of T6511 aluminum. This stress reduction improves machinability and enhances dimensional accuracy. Also, tight tolerance is maintained.

Recommended Machining Practices

6061-T6511 Some recommendations for machining practices are given below.

Cutting Tools:

High-speed steel or carbide hard material tools should be used.

Cutting Speeds:

250 to 500 SFM optimal speed range should be used for cutting.

Feeds:

Per tooth 0.005- and 0.20-inches feed rates should be maintained.

Coolants:

Mist or water-soluble coolant is used to avoid heating and for a good surface finish.

Surface Finishing Options

Anodizing, painting, and powder coatings are suitable surface finishes for 6061-T6511 aluminum which improve its aesthetic appearance and increase corrosion resistance.

Aesthetic anodized Aluminum 6061 T6511.

Everything You Want to Know About Aluminum 6061 T6511

Thermally treated alloy Aluminum 6061 T6511 is well known for its ease of machining, ductility, corrosion resistance, formability, and versatility. Aluminum 6061 T6511 is ideal for precise engineering applications like structural components, automotive, and aerospace.

Metallurgical Differences between T651 and T6511

6061-T6511 aluminum involves an additional process of mechanical stretching which reduces internal stretches and results in improved microstructure uniformity compared to T651. This uniformity in microstructure enhances dimensional stability and mechanical properties.

6061 T6511 aluminum vs 7075

6061 T6511 aluminum contains magnesium and silicon as major alloying elements but 7075 also consists of zinc in it. 7075 has high strength and is used in applications where weight is a key consideration.

Applications of 6061-T6511: Versatility Across Industries

6061-T6511 aluminum due to its versatility used in is many applications some of them are listed below.

- Aerospace for aircraft components.

- Automotive for chassis parts.

- marine for boat structures

- construction for building frames

- consumer products like bicycles etc.

Conclusion: 6061-T6511 Aluminum – The Ideal Choice for Demanding

It is concluded that with heat treatment the additional steps like stretched stress relieving and tempering have further improved mechanical properties, dimension tolerance, and corrosion resistance compared to other 6061 aluminum series. CNC-machined 6061-T6511 Aluminum is effectively can be manufactured by Tuofa. The link is given below https://www.tuofa-cncmachining.com/products/

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What is S5 Tool Steel? Tuofa CNC Machining

What is S5 Tool Steel? Tuofa CNC Machining