304 Stainless Steel: Properties, Fabrication, and Applications

Sep 03,2024

Sep 03,2024

If you are searching for the best grade of all steel grades which requires high strength and corrosion resistance, then this article is going to be helpful for you. Stainless steel 304 is one of the most used which accounts for more than 50% of all stainless steels because of its excellent corrosion resistance and durability. It is an austenitic stainless steel which makes it non-magnetic, less thermal and electrical conductor. This article explores the properties, fabrication methods and applications of stainless steel.

What is 304 Stainless Steel?

AISI 304 Stainless Steel is an austenitic steel which is commonly known as nickel-chromium stainless steel because it consists of mainly 8% Nickel and 18% Chromium and known as 18/8 Stainless Steel. It shows high resistance to corrosion, high durability, machinability and weldability which makes it more attractive for manufacturing, construction and other industries as compared to other types of steels. The tag AISI (American Iron and Steel Institute) identifies its commercial availability of stainless steel.

Is 304 Stainless Steel Good Quality?

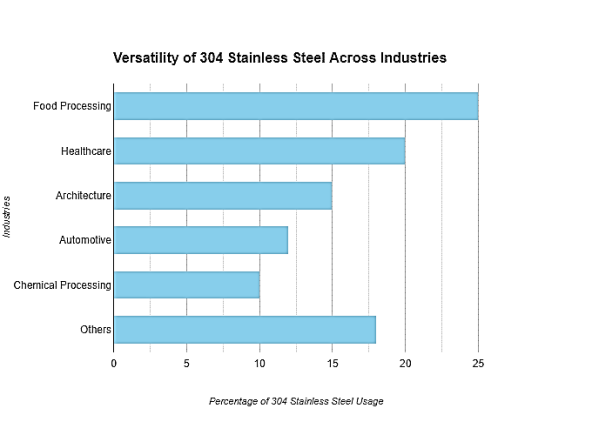

Yes, you can rely on this type of stainless steel because it is known for its excellent corrosion resistance, durability, and versatility. All these properties come from its composition i.e. Iron, Chromium, Nickel and other alloying elements. It is used from kitchen accessories to architectural structures. Its ability to resist and withstand in corrosive environments and maintain its integrity makes it reliable choice in many industries. So yeah, 304 stainless steel is a good quality type of stainless steel. Following graph shows its versatility in different industries which shows it’s a good quality and reliable type of stainless steel:

Is 304 Stainless Steel Magnetic?

If you think AISI 304 Stainless Steel shows magnetic behavior, then you might be wrong. Since it has an austenitic microstructure which has FCC crystal structure that’s why this grade is non-magnetic. As you know, 304 stainless steel is composed of iron, nickel and chromium and other alloying elements, so Ni is the actual element which makes it non-magnetic by stabilizing austenitic phase at room temperature, preventing from being ferromagnetic, unlike ferritic or martensitic steels which are magnetic.

Is 304 Stainless Steel Food Grade?

If you must select a food grade metal then there are some requirements to be fulfilled first which are the finish of the metal, its cleaning etc. So, there are only two steels which are the best to resist corrosive environment and resistant to wear and tear. Stainless steel 316 and stainless steel 304 are those steels. 304 stainless steel is a food grade, and 316 stainless steel is used as medical grade i.e. surgical equipment etc. Since the Cr is present in the composition of both grades which makes them corrosion resistant.

Does 304 Stainless Steel rust?

if you are in doubt that either 304 stainless steel rusts or not, so you should not worry about its rusting. 304 stainless steel contains 18% Chromium and Cr is the element which provides corrosion resistance. If the environment is very low or medium corrosive, then 304 stainless steel is the most reliable grade in all the steel grades because it shows both high strength and corrosion resistance.

Is 304 Stainless Steel safe for food?

Yes, you shouldn’t be worried about usage of stainless steel in the food industry. In the food industry, cleaning and wear and tear are the main issues. Since this grade has both Ni and Cr, that’s why there is no doubt on its wear and tear and corrosion resistance. You should feel safe regarding usage of 304 stainless steel for the food.

Is 304 Stainless Steel Safe for Drinking Water?

For drinking water, main issue is surface finish of the glass etc. like if you drink water and metal is facing wear and tear issue, small particles will be mixed while drinking water. So, the metal which must be used for storage of water or as a glass or bottle etc. should has a great smooth surface finish and wear and tear resistance. Since, 304 stainless steels has austenitic microstructure which makes it machinable because of soft microstructure, it becomes safe to use because of wear and tear chances. Secondly and most importantly, it shows corrosion resistance which makes it suitable for storage or drinking water.

What is SS 304 Alloy Equivalent to?

As we know 304 stainless steel is the most used and versatile grade of all steels, it has multiple designations in the different countries, some of the equivalent designations are discussed below:

|

Standard |

Equivalent Grade |

|

UNS (Unified Numbering System) |

S30400 |

|

ASTM (American Society for Testing and Materials) |

A240, A276 and A312 |

|

BS (British Standard) |

304S15 |

|

JIS (Japanese Industrial Standard) |

SUS 304 |

|

EN (European Norm) |

1.4301 |

|

DIN (German Institute for Standardization) |

X5CrNi18-10 |

Some alloys can be compared in terms of properties with this grade and are discussed here e.g. SS 304L is like SS 304 but has less content of C, which makes it less susceptible to Intergranular Corrosion and more weldable, SS 201 has lower Ni content which makes it less corrosion resistant. It is used where cost is the primary preference.

For further information related to stainless steel 304, visit following videos:

What Are the Common Forms of Stainless Steel 304 (1.4301)?

Stainless steel 304 comes in various forms in the market like sheets, bars, plates, wires, pipes, strips and foils etc. Sheets and Plates are used in kitchen accessories, automotive panels, architecture applications. Wires are used in springs, welding applications. Bars are used to make fasteners and bolts etc. Tubes and Pipes are used for fluid transport, exhaust systems etc. Strips and foils are used for electronic components and small-scale manufacturing.

AISI 304 Chemical Composition

Chemical composition of Stainless Steel 304 is presented in following table:

|

Fe |

C |

Cr |

Ni |

P |

Si |

Mn |

S |

|

70-74% |

0.08% |

18-20% |

8-10% |

0.045% |

1% |

2% |

0.03% |

Fe and C are main elements which make steel actually and other elements play their role as alloying elements which is further discussed below:

Cr provides corrosion resistance to steel.

Ni provides corrosion resistance and high strength.

2.0% Mn increases hardness of the steel which makes it suitable for usage in rails, safes etc.

P is added to in steel from 0.025-0.04% in steel afterwards it becomes impurity especially when C content is high. It is added to the steel to increase the strength of the steel.

Like Mn, Si increases the strength of the steel and makes it more reliable to use.

S is considered as technological impurity likewise P in the steel. If its mass% increases beyond the limit i.e. 0.03% it decreases toughness, ductility, wear and corrosion resistance.

The main constituents which this grade different than others are mass% of Ni and Cr which are 8% and 18% respectively which make it more resistant to corrosion and wear and tear as compared to others.

Physical Properties of SS304

The Applications of the any material depend on its physical and mechanical properties, that’s why it is important to discuss these properties. Physical properties of any material include density, melting point, thermal conductivity, electrical resistivity, and magnetic permeability. Physical properties of SS304 are briefly discussed below:

Density:7.9 g/cm3, density plays its role in weight and balance. Its density makes it suitable for automotive and aerospace parts.

Melting Point:1300ᵒ C - 1400ᵒC, this property makes it suitable for use in high temperature applications like heat exchangers.

Electrical Resistivity: (0.72 ևΩ.m) and Magnetic Permeability (≤1.02) make it useable for medical and structural applications.

Corrosion Resistance of SS304

As you know the composition of SS304 and it is explained above as well, SS304 contains 8% Ni and 18% Cr which increases its corrosion resistance. In its composition, Cr makes an oxide layer of CrO2 on steel and Ni further supports. This oxide layer protects it from rusting/corrosion during usage in any field. Its high corrosion resistance makes it useful for oil and gas pipes, kitchen utensils, medical equipment, fluid transport etc.

Mechanical Properties

Mechanical Properties of SS304 decides its applications in different fields. These properties are discussed briefly below:

Tensile Strength ranges from 550 MPa to 700 MPa which makes it useful for structural components in applications.

Yield Strength ranges from 200MPa to 250MPa which makes it useful for load-bearing applications.

Elongation ranges from 30%-40% which makes it a ductile grade and more machinable.

SS304 has a hardnes of 70HRB which provides wear resistance in machinery.

It has fatigue strength of 230MPa which is crucial cyclic loading in mechanical parts.

It has moderate creep strength which allows its usage under 600ᵒC.

Shear Strength of 310 MPa helps this grade to be used as fasteners and bolts.

Impact Strength (Charpy) of 70J provides a decent impact resistance.

Modulus of Elasticity is 193GPa which provides flexibility in the construction field.

The poison Ratio of SS304 is 0.3 which provides decent deformation limit under load.

These mechanical properties make SS304 suitable for almost every application.

Fabrication

The austenitic microstructure of SS304 makes it softer than other grades which provides an easiness to form, welds, machine etc. further fabrication processes are described below:

Cold Working

Cold working of SS304 is done at room temperature through rolling process. It is a deformation process which is also known as a strengthening mechanism. Cold working is done to enhance the strength and hardness of the steel. Cold working includes processes like rolling to make sheets, drawing to make wires etc. Cold worked products are used in aerospace and automotive industries where high strength is the primary requirement.

Hot Working

Hot working of SS304 means to deform the steel above its recrystallization temperature to improve ductility and toughness. Generally, hot working is done at 60% of melting point of that metal. In the case of SS304, this temperature ranges from 900ᵒC to 1100ᵒC. Ductility and toughness of the steel increases due to grain refinement in hot working. Common processes which are used in hot working are hot rolling to produce plates and sheets etc. Forging to produce gear and shafts etc. and Extrusion to produce complex shapes.

Machinability

SS304 is an austenitic stainless steel which has fcc crystal structure. This microstructure induces softness in this grade which makes it easier to machine. This structure helps in forming complex shapes.

Weldability

If you want to weld any metal, you need the properties like toughness and ductility from that metal because welding generates stress, so material must bear stress and resist fracture. As you know, SS304 has an austenitic crystal structure which has a face-centered cubic crystal structure, that’s why it has soft microstructure which makes it easy to weld because it has more toughness than others.

Heat Treatment

The purpose of heat treatment of the components is to relieve the stresses which generate during the manufacturing process, to induce better properties like toughness and ductility etc. Common heat treatment processes for SS304 include Solution Annealing (1040ᵒC – 1150ᵒC) to restore corrosion resistance by dissolving chromium carbide and Stress Relieving (550ᵒC - 760ᵒC) to remove stresses from the component etc.

Applications of SS 304

Since SS304 is one of the best grades of all the grades of steel that’s you will find its applications everywhere from kitchen to aerospace. That’s why it is known as the most versatile grade. Following is the some of its applications:

- Architectural applications like facades, railings etc.

- Medical applications like dental tools etc.

- Automotive applications e.g. trim, exhaust systems etc.

- Marine Applications

- Kitchen and food processing equipment

- Fasteners and Flange manufacturing

- Chemical Containers, including for transport

304 Stainless Steel Comparisons

Different grades of steel are compared below with SS 304:

304 Stainless Steel vs 304L vs 304H

|

SS 304 |

SS 304L |

SS 304H |

|

High C content which leads to be more suspected towards intergranular corrosion |

Low C content which makes it less susceptible to intergranular corrosion |

It has higher strength at high temperature than these grades due to high C content. |

304 stainless steel vs 409

|

SS 304 |

SS 409 |

|

This grade shows non-magnetic behavior due to austenitic microstructure. |

Shows magnetic behavior due to ferritic microstructure. |

|

It has corrosion resistance. |

It has lower corrosion resistance. |

304 vs 303 stainless steel

|

SS 304 |

SS 303 |

|

High corrosion resistance due to higher Cr content |

Low Corrosion resistance |

|

Less machinability |

Improved machinability due to higher content of S |

430 stainless steel vs 304

|

SS 304 |

SS 430 |

|

High corrosion resistance |

Low corrosion resistance |

|

Non-magnetic properties due to austenite. |

Shows magnetic properties because of ferritic microstructure |

All these comparisons prove why stainless steel 304 is best grade than others.

Choose Tuofa to customize CNC 304 Stainless Steel Parts

If you need precise and durable stainless steel 304 parts, then you are at the place, you should chose Tuofa. We offer you the most precise and best quality custom parts made with advance CNC technology. If you need any parts for industrial, automotive or other uses, Tuofa will be your reliable partner.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

1095 Steel for Knives Making: Beginners Guide

1095 Steel for Knives Making: Beginners Guide