What is 8620 Steel? Complete Guide 2025

Jul 30,2024

Jul 30,2024

AISI 8620 alloy is known for its high corrosion and wear resistance and strength. This is due to its unique chemical composition. It is mostly employed in oils rigs for drilling. There is a lot more about SAE 8620 steel if you are working with this material. This article will help you understand its core strength and all the possible applications for nay project.

What is 8620 Steel?

AISI 8620 is kwon as low carbon alloy. It has chromium, nickel and molybdenum as alloying elements in its chemical composition which is the reason for its high core strength. It is normally employed in anneal condition with high hardness up to 255HB. When this alloy in its case hardening conditions it has high wear resistance. Compared to other grades of 8000 series, SAE 8620 steel shows better core strength, toughness, and corrosion resistance.

Is 8620 Carbon Steel?

Yes, SAE 8620 steel is a low carbon steel. it also has Ni, Cr and Mo in its chemical composition. It has better properties in carburized form.

Is 8620 Stainless Steel Magnetic?

No, AISI 8620 alloy is not magnetic and cannot be magnetized. It is famous for its high hardness due to case hardening and high core strength.

What Are the Common Forms of 8620 Stainless Steel Material?

The common form and size of AISI 8620 alloy is as:

|

Forms |

Size mm |

Processing |

|

Round |

6-100 |

Cold drawn |

|

16-350 |

Hot rolled |

|

|

90-1000 |

Hot forged |

|

|

Flat/ Blocks /square |

Thickness: 120-800 |

Hot forged |

|

Width- 120-1500 |

Material Standards and Equivalent Material

Material standards and Equivalent grades for SAE 8620 steel are as:

|

Country |

standard |

grades |

|

USA |

ASTM A29 |

8620 |

|

DIN |

DIN 1654 |

1.6523/21NiCrMo |

|

EN |

En 10084 |

1.6523/20NiCrMo2-2 |

|

BS |

BS 970 |

805M20 |

|

Japan |

JIS G4103 |

SNCM220 |

Advantages and Disadvantages of 8620 Alloy Steel

Advantages of AISI 8620 alloy

- High durability and core strength: 8620 is famous for its high strength. this is due to presence of nickel and chromium which makes it suitable for many applications which require strength and durability.

- Low melting point: 8620 has very low melting point as compared to other carbon steels. This is a preferred feature in production and processing of materials.

- High mechanical properties: SAE 8620 steel offers robust mechanical features like wear resistance, corrosion resistance, core strength, hardness due to its unique chemical composition.

Disadvantages of AISI 8620 alloy

- Low weldability: welding of AISI 8620 alloy can be challenging and requires special equipment and skilled labor. Also, welding can decrease the mechanical features of SAE 8620 steel.

- High temperature oxidation: oxidation can occur at elevated temperatures which can reduce the service life of alloy. heat treatments are necessary to overcome this issue.

What is 8620 Stainless Steel Used for: Applications and Parts

There are many applications of ASIS 8620 alloy.

Gear Manufacturing

High toughness, wear resistance and core strength due to case hardening make it ideal for gears manufacturing. It can withstand heavy loads and friction. It is a common to use in automotive transmission and industrial machineries.

Automotive parts

Automobile parts like crankshafts, camshafts or connecting tods are mostly made of SAE 8620 steel. It can withstand high loads and strain which is ideal for critical engine components.

Structural components

8620 is employed in construction where a combination of strength and ductility are required. In mechanical systems, it is employed in shafts, pins and axle and other important parts.

Heavy Machineries

Machinery like mining equipment, agricultural, construction and transportation are mostly made of AISI 8620 alloy due to high wear resistance and toughness.

Composition and Microstructure

Chemical composition has a great impact on microstructure. 8620 chemical composition and microstructure details are as:

Chemical Composition

|

Elements |

Percentage |

|

Carbon |

0.18--.23% |

|

Manganese |

0.9% |

|

Phosphorus |

0.035% |

|

Sulfur |

0.04% |

|

Silicon |

0.35% |

|

Chromium |

0.6% |

|

Nickle |

0.7% |

|

Molybdenum |

0.25% |

Presence of Cr, Ni and Mo are reasons for high corrosion resistance, toughness and wear resistance, respectively. Low carbon can increase ductility, but carburizing increases its hardness.

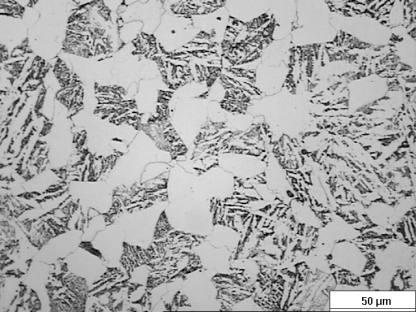

Microstructure

SAE 8620 steel is a low carbon alloy to mainly contains pearlite and ferrite in its microstructure. It is normally in the form of a hot bar rolled and cold processed to contain proeutectoid and Widmanstätten ferrite.

Corrosion Resistance

The outstanding feature of SAE 8620 steel is its corrosion resistance. presence of chromium increases its endurance to many environments. It is a common material to use in oils rigs for better corrosion properties.

Atmospheric corrosion

It has better resistance to environmental corrosion. It can survive outdoor environments without losing its mechanical properties and other reliable features.

Aqueous corrosion

This alloy has outstanding resistance to harsh environments like salty water and seawater. It is used in pumping and drilling of oil.

High-temperature corrosion

Heat treatment is required before exposing this alloy to high temperatures to avoid oxidation. Otherwise, elevated temperature can be damaging to the properties of this alloy.

Specific chemical environments

It has high resistance to acid rain. AISI 8620 alloy can be exposed to harsh environments.

Physical Properties

The physical properties of SAE 8620 steel are as:

|

Physical properties |

Values |

|

Density |

0.284 lb/in3 |

|

Thermal conductivity |

323 BTU-in/hr-ft2-°F |

|

Thermal expansion |

6.6 BTU-in/hr-ft2-°F |

|

Poisson’s ratio |

0.29 |

|

Melting point |

2,650°F |

|

Specific heat |

1.14 x10-1BTU/lb-°F |

Mechanical Properties

The mechanical properties of AIS 8620 alloy are as:

|

mechanical properties |

Values |

|

Tensile strength |

530MPa |

|

Yield strength |

385Mpa |

|

Elongation |

14.3% |

|

Hardness |

149HB, 155HRC |

|

Impact strength |

High |

|

Fatigue strength |

1000-1350MPa |

|

Wear resistance |

High |

|

Dimensional stability |

High |

|

Toughness |

High |

Manufacturing and Process

The manufacturing processes for 8620 are as:

Forming

Forming of SAE 8620 steel can be done by conventional method before and after the heat treatment.

Welding

Gas or arc welding can be done on alloy 8620 in as rolled condition. Preheating is required at 400F

Machining 8620 Steel

Machining before heat treatment can be done on 8620. After heat treatment or case hardening, it must be minimum to retain the results of heat treatment.

Grinding

Grinding after heat treatment for 8620 can be challenging. It is recommended not to perform grinding after case hardening of AISI 8620.

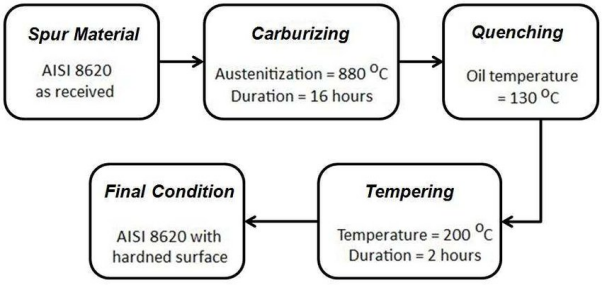

How to heat treat 8620 steels

The heat treatment of AIS 8620 alloy are as:

|

Heat treatment |

Annealing |

Normalzing |

|

Temperature |

850℃ |

920℃ |

|

Cooling |

Furnace |

Air cooling |

|

Cooling rate |

Slow |

Fast |

|

Hardness |

187HB |

200HB |

|

Cycle |

Long |

Short |

|

Grain size |

Normal |

Good |

Quenching and tempering

|

Heat treatment |

Values |

|

Carburizing Temperature |

920 ℃ |

|

Quenching temperature |

820℃ |

|

Quenching medium |

oil |

|

Tempering temperature |

200℃ |

|

Hardness |

58HRC |

|

Core hardness |

47HRC |

Summarize Differences Between of 8620 Stainless Steel Properties

The properties of AIS 8620 alloy are as:

|

Properties |

Values |

|

Density |

0.284 lb/in3 |

|

Melting point |

2,650°F |

|

Tensile strength |

530MPa |

|

Hardness |

149HB, 155HRC |

|

Impact strength |

High |

|

Fatigue strength |

1000-1350MPa |

|

Wear resistance |

High |

|

Dimensional stability |

High |

|

Toughness |

High |

Design Considerations for 8620 Stainless Steel CNC Parts

8620 stainless steel rust

Rust prevention properties in 8620 steel are high. It cannot rust in atmospheric conditions.

Mechanical requirements

Heat treatment increases the mechanical properties of 8620. Case hardening adds the hardness in SAE 8620 steel.

Corrosion resistance requirements

Corrosion resistance of 8620 is very high and it can survive harsh conditions.

processing considerations

AISI 8620 alloy can be processed with any conventional methods. However, after heat treatment, different factors must be considered and usually it is not recommended to undergo processing after heat treatment.

Cost-effectiveness

AISI 8620 is a cost-effective material. This is due to chemical composition which does not contain expensive elements in heavy amounts.

AISI 8620 VS Other Material

4140 vs 8620 steel

4140 has higher hardness than 8620.

4320 steel vs 8620

4320 has higher wear resistance and abrasion resistance than 8620.

8620 vs 8630 steel

8620 and 8630 have almost the same properties. Except 8630 has higher carbon

8620 vs 9310 steel

9301 has high shock resistance and can endure more stress than 8620.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

S7 Steel: Properties, Uses, and Heat Treatment

S7 Steel: Properties, Uses, and Heat Treatment