T6 Temper Aluminum: A Comprehensive Guide for Engineers and Machinists

Aug 19,2024

Aug 19,2024

The durability and strength of T6 aluminum is enhanced by heat treatment process.For precise manufacturing and improved machine understanding T6 tempering is very important for machinists and engineers. T6 aluminum improves aluminum strength and makes its manufacturing easy. For high-quality CNC machining service of aluminum t6 temper that ensures reliable and top-notch performance Tuofa is the best choice. Tuofa CNC has experienced workers who provide excellent service.

What is T6 Temper?

T6 temper is the heat treatment process used for aluminum alloys which includes solution heat treatment and artificial aging afterwards. These two processes are designated as T6 temper in the designation system. T6 aluminum strength is more than normal aluminum.

T6 tempered aluminum CNC machined component.

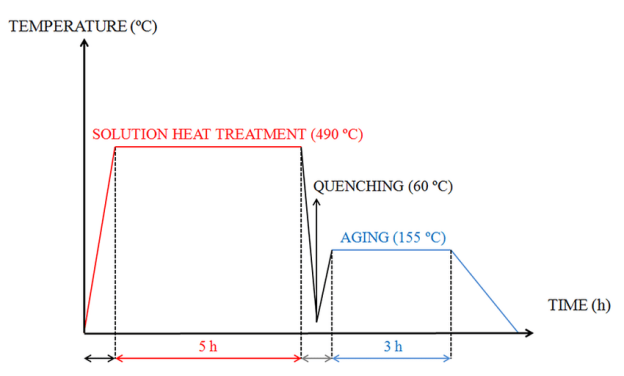

Aluminum T6 Heat Treatment Process

This T6 temper process includes two steps discussed below.

Solution heat treatment:

In this process, aluminum is heated at a constant temperature (above 500 °C) for several hours which homogenizes the alloy solution. The alloy elements dissolve into the solution making the material more durable.

Artificial aging:

After solution, heat treatment material is quenched in water and then re-heated at a lower temperature (150-200 °C). This process allows alloying elements to precipitate out and make supersaturated solutions. This process increases the overall strength of the alloy.

T6 tempering of aluminum schematic.

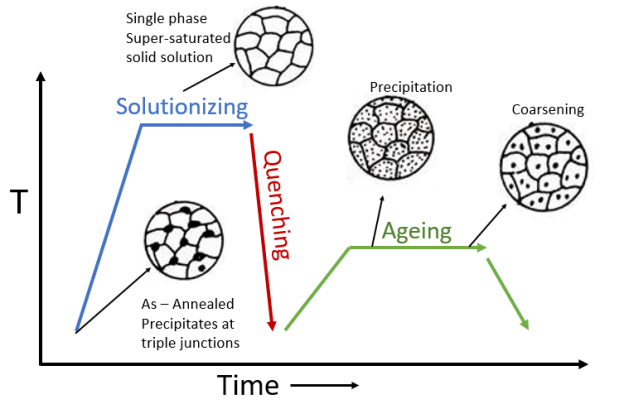

Metallurgical Changes

A single-phase solution is initially made when alloying elements are dissolved in aluminum matrix when heated to specific temperature. And heating for long at that temperature in grain in aluminum matrix grows faster. This process increases the toughness and durability of the aluminum. T6 aluminum strength is enhanced when quenched in water after solution heat treatment. In quenching the dissolved alloy elements are precipitated out making supersaturated solution. Tempering is done to remove internal stresses produced during fast cooling and the precipitates are coarsened in tempering.

Microstructure evolution during T6 tempering.

YouTube video explaining T6 aluminum tempering for different aluminum alloys.

666

Specific Standards

ASTM B221 is used for bars, wire, profiles, rods, and tubes of aluminum and aluminum alloys while ASM 4027 Is used for plates and sheets of aluminum alloy 6061-T6.

Effect of Alloying Elements

The composition of the aluminum alloy affects their response to the tempering which is explained by giving two examples of 6061 and 6063 aluminum. In the case of 6061, the tempering causes a superior increase in hardness and strength that’s why it is used in structural applications. This is due to the higher content of alloying elements magnesium and silicon. In the case of 6063 having a lower alloying element improves their extrudability and provides a better finish that's why used in decorative and architectural uses.

The Benefits of T6 Temper

T6 aluminum strength is increased, yield strength is enhanced and hardness is improved by tempering. The resistance to deformation under loading is improved. In a highly stressed environment, T6 tempered aluminum shows high durability. For demanding applications T6 tempered aluminum shows better wear resistance. The ductility is reduced, and strength is increased. This increase in hardness makes aluminum more prone to cracking.

Popular T6 Aluminum Alloys: 6061, 6063, and 7075

6061 aluminum is suitable for structural application due to its excellence properties achieved by high alloying content. 6063 has low alloying content and is used for decorative and architectural applications.6063 has better corrosion resistance than 6061.

T6 properties

The mechanical properties of 6061 and 6063 aluminum alloys are given below in the table.

|

Property |

6061-T6 |

6063-T6 |

|

Tensile Strength |

290 MPa (42,000 psi) |

240 MPa (35,000 psi) |

|

Yield Strength |

240 MPa (35,000 psi) |

215 MPa (31,000 psi) |

|

Elongation |

8-10% |

8-12% |

|

Hardness |

95 Brinell |

73 Brinell |

|

Corrosion Resistance |

Good |

Better than 6061 |

|

Weldability |

Good |

Excellent |

|

Formability |

Good |

Excellent |

Other T6 alloys

2021-T6 has good fatigue resistance and strength but low corrosion resistance in comparison to 6061 and 6063 aluminum alloy. 7075-T6 has very high exceptional strength and fatigue resistance which is why used in applications like aircraft wings and fuselage. Aluminum is best to use in aircraft components due to its less excellent strength-to-weight ratio.

7075-T6 aluminum alloy aircraft component.

What is T6 Aluminum Used for?

Different T6 aluminum applications are given below.

Aerospace: Fuselage panel, landing gear, wings component, aircraft structure due to excellent strength and fatigue resistance.

Automotive: Suspension parts, Chassis components, wheels, and engine blocks due to excellent strength-to-weight ratio.

Architectural: Structural components, curtain walls, Window frames, and roofing due to high corrosion resistance and excellent surface finish.

Sporting Goods: 6061-T6 aluminum is used to make baseball bats, tennis rackets, Bicycle frames, and ski poles due to durability and less weight.

Consumer Products: Smartphones, furniture, kitchen utensils, and laptops.

CNC Machining T6 Aluminum: Tips and Techniques for Optimal Results

Flowing tips should be considered while machining aluminum T6.

- High-speed steel or carbide hard material tools should be used.

- 250 to 500 SFM optimal speed range should be used for cutting.

- Per tooth 0.005- and 0.20-inches feed rates should be maintained.

- Mist or water-soluble coolant is used to avoid heating and for a good surface finish.

Practical Tips

For achieving optimal surface finishes, tool life, and dimensional accuracy use hard cutting material, optimum speed, maintain feed rate and use coolant.

Aging Kinetics

Short aging time gives optimal strength but a long time causes coarser precipitation which increases hardness and decreases ductility. Aging must be done at a particular temperature. Aging at high temperatures causes aging which may cause fast precipitation, but strength is decreased.

Testing Methods

For mechanical properties analysis, T6 aluminum is passed through tensile test, fatigue test, stress corrosion cracking test, and hardness test.

Tuofa CNC Machining's Expertise

Tuofa CNC Machinings show extensive expertise in manufacturing high-quality products. Tuofa CNC machining has efficient and precise equipment. They have skilled workers who provide custom solutions and assure the quality of the product. You can contact them on the website below

Beyond T6: Exploring Other Aluminum Tempers

- T3 vs T6 Temper

T3 compared to T6 involves solution heat treatment afterward cold working is done and then natural aging is done.

- T4 vs T6 Temper

T4 the time of natural aging is long which is done after solution heat treatment. This long natural aging is done to provide a balance between ductility and hardness.

- T5 vs T6 Temper

T5 compared to T6 the solution heat-treated alloy is cooled and then subjected to artificial aging.

- T7 vs T6 Temper

In T7 stabilizing aging is done after solution heat treatment.

Try Tuofa Now!

Custom solutions for complex designs: send drawings to info@tuofa-cncmachining.com

Real human quotes are more accurate than software quotes

Common Misconceptions About T6 Temper

Misconception: For all aluminum alloys T6 is the strongest temper.

Not for all T6 is the strongest it works well on 6061 and 7075 but for others, T7 and T8 are also stronger and the best choice.

Misconception: For all applications, T6 is the best choice.

The temperature depends upon the application type. Each temper enhances different properties and so can be selected on the basis of application requirements.

Conclusion

It is concluded that T6 temper improves the durability and strength of the aluminum making it suitable for different applications. However, for different applications and alloy types, the tempering type may vary. Each tempering type enhances different levels of mechanical properties which can be selected on the basis of application.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Zinc Plated vs. Stainless Steel: Which Material is Right for Your Application?

Zinc Plated vs. Stainless Steel: Which Material is Right for Your Application?