All About D2 Steel: Properties, Composition, and Knife Applications

Aug 29,2024

Aug 29,2024

D2 tool steel is a semi-stainless steel. In industrial tooling, specifically in custom knife making field, D2 steel stands out as a preferred material among manufactures and artisans. It is famous for its high edge retention, wear resistance, and hardness. D2 tool steel has major applications in long production cold working which demands high strength and wear resistance. there are many other benefits associated with the D2 steel due to outstanding properties. This article will explore more advanced features about D2 steel along with applications and other important engineering aspects.

What is D2 Steel?

D2 tool steel has high chromium content and an air hardening tool steel. It has excellent edge retention and abrasion properties. it has great response to heat treatment which further increases its hardness and has high machinability in annealed state. D2 steel becomes slightly distorted when perfectly hardened. The high chromium content in this alloy offers mild corrosion resistance in the hardened state.

Is D2 Steel Stainless?

D2 tool steel is a semi-stainless steel. It is durable and wear resistance like stainless steel but not corrosion resistant as stainless steel. It is prone to corrosion in moist, acidic or harsh environments and tool performance can be reduced.

Is D2 Steel a Good Steel?

D2 tool steel can be categorized as high-quality steel. it can survive heavy impact and wear. It also has high resistance to cracking, chipping or failure. Therefore, it is an ideal material for knives and has better edge retention. The tool performance is outstanding when subjected to high loads or impacts.

D2 Steel Equivalents in Different Countries

D2 steel, a high chromium content alloy, is widely sued tool steel around the world with various specifications.

|

Country |

standards |

Grades |

|

UK |

BS4659 |

BD2 |

|

USA |

AISI |

D2 |

|

SAE |

J438 |

|

|

ASTM |

A681 D2 |

|

|

UNS |

T30402 |

|

|

Germany |

Werkstoff |

1.2379 |

|

DIN |

X155CrVMo12-1 |

|

|

Eurnorm |

- |

X153CrMoV12 |

|

France |

AFNOR |

X160CDV12 |

|

Sweden |

SIS |

2310 |

|

Spain |

UNE |

F5211/F520A |

|

Japan |

JIS |

SKD10 |

|

Russia |

GOST |

Ch12F1 |

Can D2 Steel Be Used for Outdoor Knives?

D2 steel knives are best choice for outdoor use. They can be used while camping, fishing or hunting. It has ability to cut through tough material like ropes or branches. And it is less likely to break or fail than other conventional tool steel knives.

D2 Steel Composition

The chemical composition of D2 steel is as:

|

Elements |

Percentage |

|

Carbon |

1.55% |

|

Manganese |

0.45% |

|

Vanadium |

0.8% |

|

Chromium |

12% |

|

Molybdenum |

0.85% |

Detailed Chemical Composition

D2 tool steel is a semi-stainless steel. It has high carbon content which increases its hardness and wear resistance. high chromium content increases corrosion properties and strength, molybdenum and vanadium presence increase toughness and edge retention. While other alloy elements in small amount increase durability and abrasion resistance.

Detailed Physical and Mechanical Properties

The physical properties of semi-stainless steel D2 tool steel is as:

|

Physical properties |

Values |

|

Density |

7.7kg/m3 |

|

Melting point |

1421℃ |

|

Specific heat |

460J/kgK |

|

Thermal conductivity |

20W(MK) |

|

Thermal expansion |

10.4 x10-6℃ |

The mechanical properties of semi-stainless steel D2 tool steel is as:

|

Mechanical properties |

Values |

|

Ultimate tensile strength |

780MPa |

|

Yield strength |

320Mps |

|

Modulus of elasticity |

180GPa |

|

Elongation |

16% |

|

Hardness |

260HB 62HRC |

|

Fracture stress |

723MPa |

|

Fracture strain |

1.97% |

|

Poison’s ratio |

0.28 |

|

Modulus of toughness |

81MPa |

Corrosion Resistance

D2 tool steel is a semi-stainless steel. It has mild corrosion resistance. it is much less than other high chromium content steels. To prevent rust, proper care and maintenance is required.

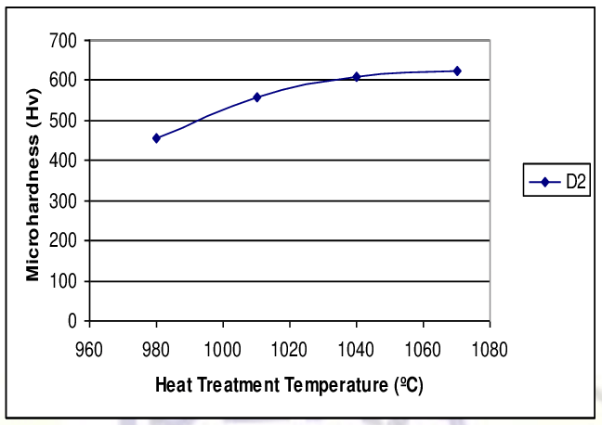

Hardness

D2 steel has high hardness due to high chromium content. The Rockwell hardness 62HRC of D2 tool steel allows blade to have edge retention for a prolonged time. The air hardening increases its hardness. This feature makes it a popular choice for cutting applications.

Wear Resistance

D2 steel has high wear resistance. It is suitable for cutting, chopping and slicing and applications where edges are subjected to wear. This high tool performance makes it stand out in industries for industrial tooling.

Toughness

D2 steel has high toughness. It can withstand high impact forces without breaking or failing. But it has lesser toughness than other steels used as industrial tooling.

How D2 steel behaves under thermal stress.

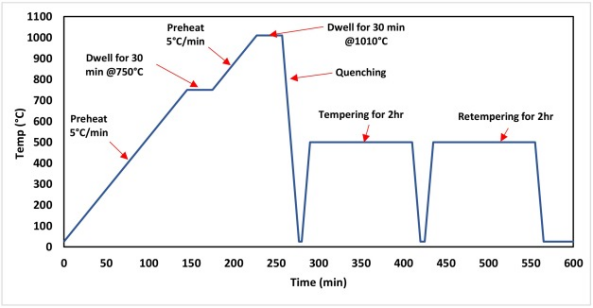

D2 tool steel shows minimal distortion under any kind of stress. To further reduce distortion by thermal stresses, preheating is recommended twice at controlled rate of 222℃ per hour. Air hardening also reduces the risk of thermal stress cracking.

Heat Treatment Processes

The response to heat treatment processes of D2 steel is as:

Forging D2 Steel

Uniform and slow heating is recommended for forging. Soaking at 1950ᵒF and reheating is done which is followed by cooling till 1700°F. D2 is annealed after forging.

Annealing D2 Steel

Annealing is carried out at 870°C, holding for 2 hours, and then slow cooling 15° per hour to till 540°C. Finally, it is then air cooled. Or it is heated till 870°C, holding for 2hrs and cooling to 775°C followed by air cooling.

Hardening D2 Steel

D2 tool steel is suitable for air hardening. Preheat and then heating to 750-800°C to fully soak at the heat. After that temperature is increases to 1040°C for air cooling. Soaking in heat for 30mins/25mm which is then followed by quenching.

Tempering D2 Steel

Tempering is recommended twice to reduce retained austenite. D2 tool steel tempering right after the air hardening at temperature of 50-70 °C.

Stress Relieving

Stress relieving for annealed D2 steel is carried out at 675°C, holding for 2hrs, and then air cooling. For air hardening D2 steel parts, heating till 25°C) holding for 2hrs and then air cooling.

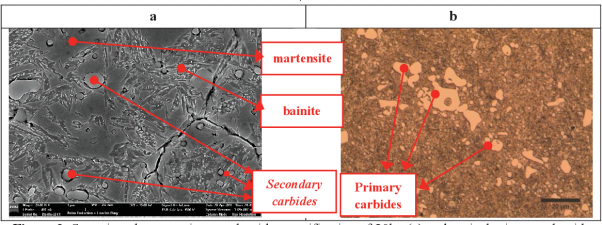

D2 Steel’s Carbide Structure

D2 tool steel has high carbon and high chromium content. The air hardening D2 steel has high hardness and chromium rich carbides in the microstructure. The carbide formation is primarily due to alloying elements. The primary carbide formation takes place is M7C3 carbides. The secondary matrix is based on ferritic-chromium-molybdenum-vanadium.

How Carbides Enhance Performance

Carbide formation enhances the hardness in D2 tool steel. their morphology is rod-like, course bulky and the tortuous carbide formation which enhances the mechanical features.

Why D2 Steel is Popular in Knives

D2 steel knives are famous among professional chefs. These have high durability, edge retention and toughness. They can survive high impacts and cannot easily crack or break. D2 tool steel blades are sharp, and they are overall famous in industrial tooling for their tool performance.

Characteristics of D2 Steel Knives

There are many beneficial characteristics of D2 steel knives. These are as:

Durability and Wear Resistance

D2 tool steel has high toughness, wear resistance and can tolerate heavy impact. This is due to carbide formation in their microstructure which also increases their hardness.

Edge Retention and Sharpening

D2 steel has high edge retention and sharpness and can be sustained for a longer time. The D2 tool steel blade is very demanding due to its versatility and durability. But the high hardness can be challenging for sharpening of D2 blade. Special tools and techniques are required to sharp the edges.

Corrosion Resistance

D2 tool steel has high chromium content but not as much as stainless steels have. It is rather a semi-stainless steel. Therefore, the corrosion resistance is mild. It is prone to rust in harsh, acidic and moist environments.

Cost vs. Performance

D2 steel knives price varies with the models. It ranges between $18-$72 from basic to advanced features model. Furthermore, brand name also affects the final cost of D2 steel knives. The expensive knives are better than cheaper one in tool performance, blade edge retention and quality

Best Uses for D2 Steel Knives

D2 steel knives have various uses. Some of them are:

Folding Knives

D2 steel knives have high hardness, edge retention and wear resistance. They are best suited for consumers with priority of high cutting performance and tool performance. Common types of folding knives made of D2 steel are Ka Bar Dozier, Off grid caiman, Buck HiLine famous for durability and performance.

Fixed Blade Knives

D2 steel knives can be used for many applications like outdoor activities, hunting, camping, fishing because of the durability. Popular fixed blades of D2 tool steel are Buck HiLine and K Bar Dozier.

Specialized Tools and Applications

- Cutting Tools: D2 tool steel is commonly employed in the production of dies, punches, blades and other cutting tools because of their hardness and toughness.

- Forming Tools: industrial tooling parts like extrusion tooling, stamping dies, and forging tools are made from D2 tool steel due to the tool performance and high dimensional stability.

- Machine Components: D2 tool steel is employed in manufacturing of machine parts like bearing, shafts, gears, wear plates due to high strength and tool performance.

How to Maintain D2 Steel Knives

There are few tips and trick to maintain the D2 steel knives.

Cleaning D2 Steel Knives

Clean the knife blade regularly with clean cloth to remove particles and moisture. This reduces the corrosion risk and maintains the edge retention.

Sharpening D2 Steel Knives

Sharpening od D2 Steel Knives can be challenging because of hardness and carbide formation in microstructure. To sharpen the knife, coarse diamond hone or water stone must be used at 15degree/ side edge bevel for better cutting performance.

Storing D2 Steel Knives

To protect the edges, store the knife in blade guard or sheath. Knife blocks or magnetic strips must be used to store the knife blade when not using.

Tips on Taking Care of D2 Steel.

- Use oil for protection like mineral oil or wax that could protect the blade from corrosion,

- Never use dishwasher to clean the knives. As high and harsh detergent can damage the blade and knife material.

Common Misconceptions about D2 Steel Knives

- D2 tool steel is semi-stainless steel. It is not stainless steel and does not have that high chromium content. It also does not offer high corrosion resistance as conventional stainless steel does.

- D2 steel can be chipped off if it is not used with care. If high impacts are used very often, it may fail or break

D2 Tool Steel Machinability

D2 steel has high carbon and high chromium content. These are cold worked steel and have machinability rating of 27%.

Machinability and Techniques

D2 steel is also famous as air hardening or cold worked steel. It has high toughness, dimensional stability and wear resistance. This is suitable for heat treatments, which improves its hardness. When it is annealed state, it gives better machinability results.

D2 steel is machined at slow cutting speed because it gets work hardened. Oil and coolant must be used to improve the machinability.

Industrial and Tooling Applications

- Plastic Molds: D2 steel are perfect for making injection molds, compression mold and blow mold due to high wear resistance and durability

- Industrial tooling: `it is used in the production of cold worked tools like trimming dies, shearing blades or blanking dies due to high toughness.

- Aerospace and Defense: in aircrafts, it is used to make parts like landing gears, actuators and ordnance parts.

D2 Steel in Comparison

8Cr13MoV vs D2 Steel

D2 steel has better edge retention and toughness but difficult to sharpen. 8Cr13MoV can easily be sharpened and has better corrosion resistance.

Is D2 or 1095 Better?

Although D2 is semi stainless steel. but it still has better corrosion resistance than 1095. 1095 can easily be corroded and needs extra care to be protected.

Nitro-V Steel vs D2

Nitro-V Steel has better corrosion resistance than D2 steel. D2 has better edge retention.

D2 Steel vs S30V

S30V has better corrosion resistance, edge retention and can easily be sharpened than D2 steel.

D2 Steel vs S35VN

D2 has better edge retention and toughness. S35VN is easier to sharpen and has better corrosion resistance.

D2 Steel vs 440C

D2 steel has higher hardness and toughness than 440C. it can edge retention better than 440C.

54CM Steel vs D2

D2 has high toughness and edge retention but 54CM is easier to sharpen and has better corrosion properties.

Why Choose D2 Steel?

D2 steel has high hardness at higher temperatures up to 425 °C. high chromium content accelerates the carbide formation in microstructure which increases the wear and abrasion resistance. D2 tool steel has high toughness and knife can hold edges longer.

Balancing Cost and Performance

D2 steel is known for its higher 0edge retention than super steel, keeping in mind its cost-effectiveness. This is an excellent choice for budget-conscious consumers.

My Cheap D2 Folder is Better than Your Expensive Super steel

Super steel has better tool performance but D2 steel is cost effective with many of the advantages than super steel has. Many users are satisfied with the performance and sharpness of D2 knives and making it a better affordable and cost-effective choice which have comparable performance with super steels.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

18/8 Stainless Steel: Properties, Uses & Comparisons

18/8 Stainless Steel: Properties, Uses & Comparisons