1095 Steel for Knives Making: Beginners Guide

Sep 10,2024

Sep 10,2024

1095 steel is a great choice for making strong, sharp knives. In this guide, you will learn why 1095 steel is popular, its benefits, and how to use it. From heat treating to sharpening, this guide will show you how to work with 1095 steel to create long-lasting and reliable knives, perfect for both beginners and those improving their skills.

What is 1095 Carbon Steel?

1095 steel has carbon content of 0.9 – 1%, it is famous for knife-making because of its excellent edge retention, hardness and ease of sharpening. In this article you will learn why 1095 steel is best for knife community and its applications and other comparable steels.

Is 1095 Steel Good for Knives?

Yes, you will find it as the one of the best steels because it bends easily but It does not break easily. It has excellent edge retention and hardness because of high carbon content as compared to others.

Is 1095 Folded Steel Good?

The folding process is used to add some appealing looks on the knife but does not change the other properties. That’s why it is one of the best processes to make aesthetic traditional knives and it also helps in retaining the toughness.

Does 1095 steel rust easily?

Yes, you will find one issue in that steel which is rust. This problem is due to the low content of chromium. As you know Cr provides corrosion resistance, but this type of steel lacks that property because of the low content of Cr and high C content as compared to other steels.

What Grade is 1095 Steel Equivalent to?

1095 steel is equivalent to other grades like AISI/SAE 1095. It is like other alloys which include W1 tool steel and 1084 steel. These steels have the same properties as high carbon content and hardness.

What Are the Common Forms of 1095 Steel Material?

You can find 1095 steel in bars, sheets, and strips. This steel is mainly used in bladelike structures due to its hardness. It can also be found in wires and rod-like forms.

Pros and Cons of 1095 Steel:

Pros:

This steel is useful in making blade like structures due to high C content, high hardness and edge retention.

Cons:

it has poor corrosion resistance because of low Cr content.

Certifications and Standards for 1095 Alloy

Certificates

1095 steels meet with the standard of ASTM A682, which has the same hardness. Its commonly used in those applications where hardness and edge retention are primary needs.

Standards

This steel meets with the standards of practices for knife and blade production ensuring excellent performance when it is treated properly.

1095 Carbon Steel Information and Composition

Chemical Composition

1095 steel has high carbon content up to 0.9% to 1.03%, Mn up to 0.5%, Sulfur up to 0.3% and phosphorus as trace amounts.

Physical Properties

Its main physical properties include density and hardness which are 7.85 g/cm3 and 55 – 58 HRC after heat treatment respectively.

Condition

Mostly 1095 steel is supplied in annealed form which makes it easier to machine before other heat treatments.

Mechanical Properties of 1095 High Carbon Steel

Hardness and Toughness

Its hardness remains in the range of 55 – 58 HRC but mainly it depends on the respective heat treatment process. There is no single value of toughness, but it is poor as compared to other steel because of high C content.

Tensile Strength

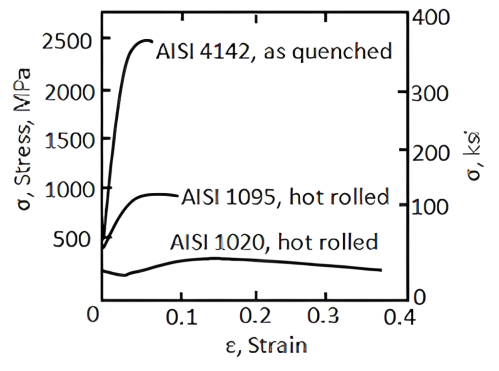

After the annealing process, its tensile strength becomes 715 MPa which can be further increase after heat treatment processes. 1095 steel is compared with other steels as you can see in the given graph:

Ratings

The only issue in this steel is its poor corrosion resistance and brittleness due to high C content. It is commonly used for blade structures because of high hardness and edge retention.

Heat Treatment of 1095 Steel

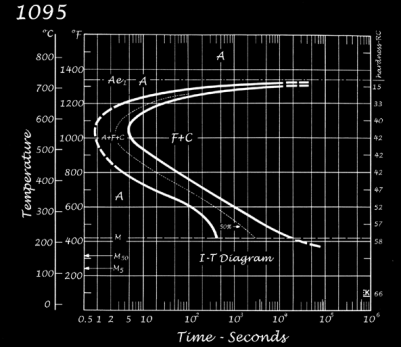

You will find this steel performs well after heat treatment processes which are commonly done at the temperature of 700ᵒC - 800ᵒC. since we need hardness, so quenching is done in water or oil.

1095 Heat Treat Information

1095 steel is usually supplied after annealing process so that its machinability becomes easy. Mainly, quenching is done as heat treatment because you need hardness as primary property. As you can see in the give graph:

What do You Quench 1095 Steel in?

Quenching of 1095 steel is done at the temperature range of 700-800ᵒC. quenching can be done both in water and oil, but oil quenching is preferable because water quenching increases the brittleness so chances of cracking increases as well.

Tempering and Annealing

Annealing is done to make 1095 steel more machinable while tempering at the temperature of 220 - 250ᵒC to regain some toughness and reduce the hardness as it is the brittleness in the product.

1095 Steel in Knife Making

Why Knife Makers Prefer 1095 Steel

There two reasons why knife makers prefer 1095 steel for making knives because firstly this steel has high hardness and secondly this steel provides high edge retention.

Tools and Machinery

Mostly blacksmithing tools, forgers, grinders and quenching tanks are used as tools and machines for making products of 1095 steel.

Creating Hamons with 1095 Steel

The pattern which gives both aesthetic look and functional help to knives is called hamons. It is a visible pattern on the knives which is created through differential heat treatments.

Machining 1095 Steel: Tips and Techniques

Cutting and Shaping 1095 Steel

When you will work with 1095 steel, you will need high-speed steel or carbide plates to cut and shape this steel because of its high hardness. A proper lubrication you should use during working to avoid overheating.

Flat Ground: A Popular Choice

Flat grounds are a popular choice for 1095 steels because they offer a balance between sharpness and durability.

Polishing and Finishing

At the time of polishing and finishing, you would require finer grits and buffing compounds to achieve a smoother and reflective surface. To reduce rust on 1095 steel you should perform bluing treatment.

1095 Steel vs. Other Steels

Is 1095 Steel Better than 1060?

1095 steel has relatively higher carbon content than 1060 steel which makes it harder but less corrosion resistant as compared to 1060 steel. 1095 steel is used in applications where high hardness is required while 1060 steel is used in automobile industries.

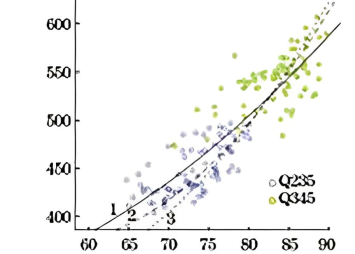

Difference in the tensile strength is shown in below graph:

1095 Steel vs. 1075 Steel

1095 steel has higher carbon content than 1075 steel. 1095 steel is used in making parts like lock picks, S-Tines and spring clamps etc. while 1095 steel is used in making knives etc.

1095 Steel vs D2

1095 steel is very hard than D2 steel because of high carbon but its easier to machine as compared to D2 so its cast is less than D2 steel. D2 steel is used in making forming rolls, punches etc.

Hopefully this article would be helpful for you to understand why 1095 steel is best for knives making, what are its pros and cons, what is its composition and how is it different than other types of steels. Conclusion of the article is that 1095 steel has high carbon content 0.9 – 1.03% which makes it more harder and gives a property of edge retention which is a helpful property in making a knife.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Polyamide vs Nylon: Which is Better?

Polyamide vs Nylon: Which is Better?