18/8 Stainless Steel: Properties, Uses & Comparisons

Sep 02,2024

Sep 02,2024

18/8 is also known as 304 stainless steels. AISI standard has designated the steel as 18/8. It is one of the most common and versatile materials in stainless steel grades. It has high corrosion resistance, durability and aesthetically appealing due to chromium oxide layer and nickel content.

What is 18/8 Stainless Steel?

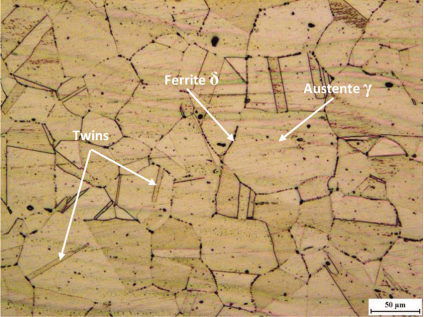

18/8 stainless steel has an austenitic structure. It is also famous as chromium steel 18/8. It has a high chromium and nickel content in composition. The chromium oxide layer over a surface creates a self-healing process for corrosion and rust. Nickle content increases the strength, formability and durability in 18/8 stainless steel. It is non-magnetic in nature. It has good response to welding techniques and heat treatment particularly annealing. It also has a food safety feature and extremely hygiene for the use in food processing industries and for food packaging.

Is 18/8 stainless steel good quality?

18/8 stainless steel is a marine grade material due to high corrosion resistance. The chromium oxide layer makes it highly corrosion resistant. Nickle content makes it high quality material with incredible durability, formability and strength.

Is it safe to drink from 18/8 stainless steel?

Yes, it is safe to drink from 18/8 steel. the austenitic structured 304 type steel is a food grade material because it provides food safety and high hygiene.

Is 18/8 steel food safe?

18/8 austenitic structure steel is a food-grade material. It is a hygiene and food safety material which can be used in utensils, cookware and for cooking worktops.

Common Designations and Standards

|

Country |

standard |

grade |

|

US |

ASTM |

A240, A240M |

|

EU |

EN-1008801 |

X5CrNi18-10 |

|

ISO |

ISO15510 |

X5CrNi-18-10, X2CrNi19-11 |

|

Japan |

JIS |

SUS304 |

|

China |

GB/T20878 |

0Cr18Ni9 |

Cost and Availability

Cost and Availability depends on factors like raw material cost, supply and demands, market conditions, logistics and shipping. 18/8 stainless steel is usually raged from $0.86-16.50/pc.

Advantages and Disadvantages of 18/8 Stainless Steel

The chromium steel 18/8 has some benefits and drawbacks. These are as:

Advantages of 18/8 stainless steel

The advantages of 18/8 stainless steel and benefits are as:

- The chromium oxide layer provides high corrosion resistance for harsh environments, moisture, chemicals, acids and other common corrosive substances.

- High nickel content provides high tensile strength and can withstand heavy loads and impacts

- The surface finishes of chromium steel 18/8 has resistance to bacterial growth. Therefore, it is easy to clean and has strong hygiene properties.

- It has food safety features and is non-risky to use in kitchen accessories, food packaging and food processing industries.

- It gives good response to heat treatment and annealing conditions. It improves strength and durability.

- It is non-magnetic in nature, and easily formable, machined and welded from conventional welding techniques.

Disadvantages of 18/8 stainless steel

The limitations of chromium steel 18/8 are as:

- The austenitic structured chromium steel 18/8 can be expensive choice due to high nickel content.

- The chromium steel 18/8 is non-magnetic in annealing conditions. It can become magnetic by cold working but not desirable in many applications.

- The chromium steel 18/8 performs well at normal temperatures. But it is not suitable for elevated temperatures.

- In some harsh environment, it may require additional surface finishes treatment to preserve surface properties and chromium oxide layer over the surface. It normally occurred in chloride environments.

How 18/8 Stainless Steel is Made

The 18/8 stainless steel manufacturing occurs through smelting in an electric arc furnace (EAF). The process is same as for conventional steelmaking process. The raw material are chromium, nickel and manganese and molybdenum. The scrap is melted by electric arc. Alloying agents are added while smelting to balance the properties. Then the molten metal goes to refining process. Once the required chemical composition is achieved, the molten metal is casted and ready for hot rolling or cold rolling processes.

Properties of 18/8 Stainless Steel

The properties of chromium steel 18/8 are as:

Corrosion Resistance

Chromium steel 18/8 has high corrosion resistance. It offers good pitting corrosion and stress corrosion cracking resistance due to chromium oxide layer. the presence of Mo in small amount improves its marine environment resistance. however, in chlorinated environments, it may show some signs of corrosion.

Physical Properties

The physical properties of chromium steel 18/8 are as:

|

Physical properties |

Values |

|

Density |

7.93 kg/cm3 |

|

Melting point |

1400-1450℃ |

|

Electrical resistivity |

0.72μΩ.m |

|

Conductivity |

2.5 %IACS |

|

Thermal conductivity |

16.92 W/m.K |

|

Specific heat |

500J/Kg.K |

|

CTE |

17.8 x10-6/K |

|

Magnetic permeability |

1.02 |

Mechanical Properties

|

Mechanical properties |

Values |

|

tensile strength |

515Mpa |

|

yield strength |

205Mpa |

|

shear strength |

High |

|

Elongation |

70% |

|

Hardness |

262Hb, 85HRB |

|

Fatigue Strength |

31.2ksi |

|

Impact Strength |

High |

Other Properties

Chromium steel 18/8 has austenitic structure. It is non-magnetic. It has good surface finishes but cannot be hardened by heat treatment. But it has high machinability and weldability. It can be welded by conventional welding techniques like TIG and MIG.

It has high formability and machinability rating up to 48%.

However, the heat resistance is moderate. It cannot work at temperatures higher than 1697°F for longer time.

Applications of 18/8 Stainless Steel

The 18/8 stainless steel applications and uses are as:

- It has high corrosion resistance due to chromium oxide layer. It is a marine grade material due to high nickel content

- Chromium steel 18/8 has high hygiene nature and food safety features. It is also food grade material that can be used in utensils, cookware and other kitchen accessories.

- It is used making equipment in food processing industries like tanks, pipes, and convers belts

- It is used in architectural elements like doors, window frames and for decorative features.

- It is used in automotive industries in making exhaust systems, trim, grills and body panels.

- It is used in making medical and surgical tools due to biocompatibility and strong hygiene.

18/8 Stainless Steel vs. Other Ferritic or Martensitic Grades

Chromium steel 18/8 has an austenitic structure. It is non-magnetic. It gives good response to all the welding techniques, heat treatment and specially annealing. Whie ferritic grades are magnetic and non-hardenable. They have lesser corrosion resistance than 18/8 stainless steel. the chromium steel 18/8 is more versatile than ferritic grades.

Martensitic grades have high carbon and hardness and strength. but has poor corrosion resistance than chromium steel 18/8. The chromium steel 18/8 has better surface finishes properties.

18/8 Stainless Steel and CNC Machining

Chromium steel 18/8 is commonly used for CNC machining part. It has high machinability up to 48% and can be precisely machined to create interictal parts. It shows high tolerance and good chip formation. It has less risk of tool wear and has overall smooth machining operation. It is important to select appropriate machining parameters to achieve good results.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Damascus Steel vs. Carbon Steel Knives: Which is the Better?

Damascus Steel vs. Carbon Steel Knives: Which is the Better?