52100 Stainless Steel: A Comprehensive Guide for Engineers and Designers

Jun 14,2024

Jun 14,2024

52100 is a high carbon steel. it contains significant amount of chromium which enhances its corrosion and mechanical properties. That is why it has become a popular choice in different industries. AISI 52100 stainless steel serves best in high loading conditions and rolling friction and for knives. 52100 knife steel is generally used in furnaces. AISI 52100 chrome steel properties are discussed below in this article.

What is 52100 Stainless Steel?

AISI 52100 stainless steel is a high-carbon alloy. This chrome alloy steel is generally used in high wear and tear and bearings applications. AISI 52100 chrome steel properties are noteworthy because it contains up to 1.6% carbon. This increases its hardness, strength, and wear resistance. This steel also designs for fracture toughness and corrosion resistance applications.

Is 52100 Carbon Steel?

Yes, 52100 steel is a high carbon alloy. It is developed in 1905 for high pressure applications. It is also known as 52100 knife steel.

Is 52100 Stainless Steel Magnetic?

Yes, 52100 is magnetic. It can stick to magnets and can conduct electricity.

What Are the Common Forms of 52100 Stainless Steel Material?

AISI 52100 Stainless Steel comes in sheet for use in machine parts, tooling and industrial parts. 52100 stainless steel bars are used in bearings, shafts, and gears. Its plates are used in heavy machineries, structural parts and tooling. Other forms include hot drawn, cold drawn, annealed, forged depending on the applications.

Material Standards

AISI 52100 stainless steel is also called 52100 carbon steel, 52100 knife steel and ASTM 52100 beating steel. First digit (5) represents it is chrome alloy. The 2nd digit (2) shows the alloying percentage greater than 1. And the last three digits shows the carbon percentage which is more than 1%.

Advantages and Disadvantages of 52100 Stainless Steel

The advantages of AISI 52100 Stainless steel are as:

- It contains high hardness after giving heat treatment of quenching, and tempering.

- 52100 knife steel has high wear resistance due to high carbon and chromium. It has ability to survive high stress without wear and tear.

- Its design for fatigue resistance can withstand cyclic loading and repeated stresses without breakdown.

- Its design for creep resistance has high load bearing capacity. This has a balances hardness and toughness with heavy loads evenly distribution.

- AISI 52100 chrome steel properties include high dimensional stability.

- One of the 52100 steel properties is its good machining into complex shapes.

The disadvantages in the 52100 steel properties are as:

- 52100 steel properties contain corrosion resistance. but it not as resistant as stainless steel.

- High carbon and alloying agents decrease its weldability. It needs preheating specific procedures like gas metal arc welding to avoids cracks.

- It has design for fracture resistance but it is prone to fracture under impact and sudden loading conditions.

- AISI 52100 stainless steel is very brittle in fully hardened state.

- It is difficult to machine in fully hardened state and requires special tools and techniques.

- It is expensive as compared to stainless steel and other common steel grade with same properties.

What is 52100 Stainless Steel Used for: Applications and Parts

Automotive industry

AISI 52100 stainless steel is used in many automotive parts like wheel bearing, transmission system and for engine components. Its design for creep resistance makes it suitable for high fatigue strength, high loading conditions and also for wear resistance.

Bearings, gears and shafts manufacturing

52100 bearing steel utilized in many small and medium sized beating parts. It is a commonly material used for machine parts, gears and for the shafts. Its design for fatigue resistance is suitable for high tensile strength and high hardness and stress corrosion cracking applications.

Aerospace industry

In aviation and aerospace industries, AISI 52100 stainless steel has many applications in critical parts of jet engines where high performance and efficiency require. It is specially used in making landing gear and flight control system. It has high resistance to temperature, and to stress corrosion cracking and chloride induces stress corrosion cracking ensures its performance in extreme conditions.

Structural components

52100 knife steel is used in making industrial machines and equipment. It utilized in building pumps, compressors and turbines. Its design for creep resistance enhances its mechanical properties which contributes to long service life and higher efficiency of machines. They require low maintenance, cost and downtime.

Ordnance components and Defense industry

52100 knife steel has many applications in ordnance parts and defense industry because of high strength, stress corrosion cracking resistance, chloride induces stress corrosion cracking resistance. it is used in building firearms, ammunition other defense equipment. It is also used in building aircraft, tanks and warships components.

Cutting tools and Tooling industry

AISI 52100 chrome steel properties includes high resistance for heavy duty applications. It is used in manufacturing beatings, shafts, tools, roll mills and other tools. The tools and machines made of 52100 knife steel have long life and high resistance to stress corrosion cracking.

Punches and dies

52100 knife steel is essentially used for high precision bearings due to its design for fatigue resistance. Its design for creep resistance improves its hardness, wear resistance and can withstand radial and axial loads. It ensures efficient operations of machines and tools.

Is 52100 Steel Good for Knives?

AISI 52100 stainless steel is very famous for making knife steel. in fact, it is also known as 52100 knife steel. This high carbon steel has high hardness and strength. hardness can increase up to 65HRD when processed after hardening.

Composition and Microstructure

Chemical Composition

52100 is a high carbon low chrome alloy steel. its high carbon increases its hardness, strength and other mechanical properties. chromium increases its resistance to stress corrosion cracking and chloride-induces stress corrosion cracking. Other elements in small amount increases its machinability, weldability for gas metal arc welding and formability. It is also known as knife steel.

|

Elements |

Percentage |

|

Carbon |

1-1.5% |

|

Chromium |

1.4-1.6% |

|

Nickle |

0.25% |

|

copper |

0.25 |

|

Manganese |

0.45% |

|

Silicon |

0.15-0.35% |

|

Phosphorous |

0.025 |

|

Sulfur |

0.025 |

Microstructure

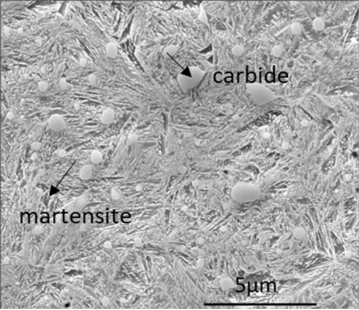

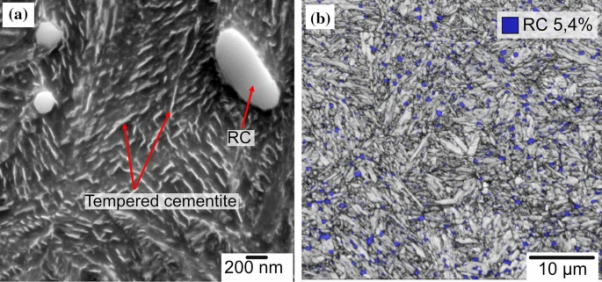

AISI 52100 stainless steel normally include cementite and martensite. As it is a high carbon steel so carbon is present in the from of carbides or cementite.

When it is tempered at high temperature, its microstructure contains tempered martensite, retained cementite, (RC), tempered cementite. It is also contained small amount of retained austenite. The figure below shows the tempered 52100 microstructure and its etched microstructure to enhance color contrast of each phase.

Corrosion Resistance

AISI 52100 chrome steel properties include high resistance to corrosion and stress corrosion cracking. It can withstand high mechanical stresses, wear, and tear. Its design for fatigue resistance increases its fatigue for a longer time. Its high corrosion resistance is due to presence of chromium content in a significant amount.

Atmospheric corrosion

Different atmospheric conditions have different effect on the corrosion performance of AISI 52100 stainless steel. presence of sulfur dioxide, water and elevated temperatures can accelerate chloride-induced stress corrosion cracking. Lack of maintenance and lack of moisture removal can also impart drastic effect.

Aqueous corrosion

AISI 52100 chrome steel properties include vulnerability of pitting corrosion in oxidizing environment. The rate of chloride-induced stress corrosion cracking is higher in oxidizing media than reducing media. The pitting corrosion rate can be identified by the idea of general corrosion rate.

High-temperature corrosion

52100 steel properties show good corrosion resistance. elevated temperature that a AISI 52100 stainless steel can withstand is around 500-600℃.threrofore hot working temperature that is recommended is up to 200-500℃.

Specific chemical environments

Presence of chromium content increases the corrosion resistance of 52100 grade. Stress corrosion cracking and chloride-induced stress corrosion cracking are good among the 52100 steel properties. pitting corrosion can be induced in different oxidizing medias. In heat treatment, water quenching is not recommended for 52100 steel. This is due to chance of corrosion. 52100 steel properties do not contains as much good corrosion resistance as of stainless steel.

Mechanical Properties

Tensile strength

Tensile strength of 52100 steel properties is 325,000 pounds per square inch and 245MPa.

Yield strength.

Yield strength of 52100 steel properties is 295,000 pounds per square inch and 203MPa.

Elongation

AISI 52100 stainless steel has elongation up to 8-25%.

Hardness

Hardness in different units in 52100 steel properties are:

|

Knoop |

Rockwell, C (oil quenching from 150°C tempered) |

Rockwell, water quenching from 150 tempered |

Rockwell, oil quenching |

Rockwell, water quenching |

Vickers |

|

875 |

62 |

64 |

64 |

66 |

848 |

Impact strength

The impact strength of AISI 52100 chrome steel properties has 52J.

Fatigue strength

The design for fatigue resistance in 52100 steel properties makes it withstand repeated loads, cycling stress or strain and dan endure strain for a longer period. For a normal steel, 5-10million cycles is its fatigue limit.

Toughness

The design for creep resistance in the AISI 52100 chrome steel properties has high toughness. It can also be further increased by heat treatment. If the austenitizing temperature kept lower, it increases the toughness of AISI 52100 stainless steel.

Wear resistance

The design for fatigue resistance and design for creep resistance both increases the wear resistance of AISI 52100 stainless steel. high carbon content increases its wear resistance and prevent it from abrasive wear in heavy loading conditions.

Dimensional stability

AISI 52100 chrome steel properties include high dimensional stability. One of the 52100 steel properties is its good stability in complex shapes in high precision bearing.

Physical Properties

The physical AISI chrome steel properties are as:

|

Physical properties |

Values |

|

Density |

7.81g/cm3 |

|

Thermal conductivity |

46.6Wm/K |

|

Electrical resistivity |

0.0000219 ohm-cm |

|

Thermal expansion |

11.99μm/m.℃ |

|

Magnetism |

Ferromagnetic, >300μ |

Manufacturing and Process

52100 steel properties has the ability to undergo different manufacturing processes.

Forming

AISI 52100 is formable by any traditional methods. These are cold forging, stamping, drawing, upset forming either cold or hot.

Welding

Welding is challenging in 52100 knife steel. the gas metal arc welding can be carried out by preparing the metal with special treatments. It can undergo cracking or stress corrosion cracking during service.

Machining

52100 knife steel can undergo machining by any conventional process. Annealing before machining gives good results.

Grinding

52100 knife steel can be grinded, forged and drawn easily by any conventional method.

How to heat treat 52100 steel

AISI 52100 stainless steel undergo normalizing at 872°C and then slowly cooled to reduce machining stress. Then it is annealed at 816°C followed by quenching in oil.

Hot working of AISI 52100 steel can be done at 205-538°C.

52100 knife steel can be cold worked in annealed and normal condition by any conventional method.

Work hardening and water quenching can be done from 801-829℃. For oil quenching it is 816-842℃

Summarize 52100 Stainless Steel Properties

|

Property |

Imperial Units |

|

Corrosion Resistance |

Moderate |

|

Machinability |

40% |

|

Wear Resistance |

Very High |

|

Hardness |

64 HRC |

|

Bulk Modulus |

20300 ksi |

|

Modulus of Elasticity |

27557-30458 ksi |

|

Shear Modulus |

11600 ksi |

|

Poisson’s Ratio |

0.27-0.30 |

|

Tensile Strength |

High |

|

Yield Strength |

High |

|

Magnetic Properties |

High |

|

Elongation |

5-10% |

Design Considerations for 52100 Stainless Steel CNC Parts

SS 52100 equivalent material

|

Country |

Grade |

|

USA |

ASTM A295 |

|

German |

DIN 17230 |

|

JAPAN |

JIS G4805 |

|

British, EN |

BS970 |

52100 stainless steel rust

52100 knife steel has chromium which makes it rust free material. but its corrosion resistance is not as good as stainless steel.

Mechanical requirements

It is a high carbon alloy which increases its hardness and wear resistance. this is suitable for bearing and cutting tools. Chromium addition makes it hardened and after heat treatment this increased further and improve corrosion resistance.

Corrosion resistance requirements

Chromium is lower than other stainless steel in 52100 knife steel. therefore, it is moderate in many conditions water quenching is not recommended because it can reduce its corrosion resistance.

Processing considerations

Processing like machining of 52100 stainless steel is vey high and up to 40%. However, high carbon content makes its welding challenging. It requires special pretreatment and welding likes gas metal arc welding can be done.

Cost-effectiveness

AISI 52100 is not a cost-effective option as comped to stainless steel due to high carbon content.

AISI 52100 VS Other Material

52100 Ball Bearing Steel vs Magnacut

AISI 52100 stainless steel has less toughness than Magnacut. Magnacut also has high wear resistance and hardness due to the presence of vanadium and niobium.

52100 Steel vs 1095

52100 is tougher than 1095. It holds edges longer than 1095. But 52100 knife steel has less corrosion resistance.

52100 Steel vs D2 Steel

D2 is more corrosion resistant than AISI 52100 stainless steel. it has more chromium up to 12%. It is a better option in stress corrosion cracking and chloride-induced stress corrosion cracking.

316 Stainless Steel vs 52100 Alloy Steel

Both are iron alloys and have 69% same composition. Mechanical properties are almost the same but due to high chromium in 316, it is more corrosion resistant than 52100 knife steel.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Bead Blasting Service: A Comprehensive Guide to Surface Transformation

Bead Blasting Service: A Comprehensive Guide to Surface Transformation