409 Stainless Steel: A Comprehensive Guide for Engineers and Designers

Jun 17,2024

Jun 17,2024

Stainless steel is one of the most durable and versatile materials known for its wider range of application in modern manufacturing era. It comprises of different grades, each with its own properties and characteristics. This article will primarily focus on 409 SS grade with is famous for its corrosion and high temperature resistant. So, regardless of your study background, you will be able to understand and make informed decisions while choosing this material for your application.

What is 409 Stainless Steel?

This material belongs to 400 series of stainless steel that are numerously used in industrial sector for their unique set of properties. The major alloying element present in this steel is chromium with small amounts of carbon and other elements. Moreover, it is classified under ferritic stainless steel due to its BCC structure with a blend of properties such as corrosion and heat resistant. Additionally, it is more economical as compared to other stainless steel and is beneficial for an industrialist while choosing budget friendly material without compromising performance

Figure 1: 409 Stainless steels

Is 409 Mild Steel?

409 SS grade is not counted as mild steel rather it is considered as ferritic stainless steel. This is because it comprises of chromium along with other alloying elements while mild steel consists of iron as major alloying element with other constituent elements. Apart from that, 409 grade SS has superior resistant to corrosion as compared to mild steel which is susceptible to rust.

Is 409 Stainless Steel Magnetic?

This grade of stainless steel is magnetic in nature because of its ferritic structure. Hence, the BCC structure makes this material capable enough to maintain its magnetic properties at room temperature as well as elevated temperature. Moreover, reasonable amount of iron also has a contribution in its magnetic behavior.

What Are the Common Forms of 18/10 Stainless Steel Material?

18/10 grade SS is well known for its numerous applications due to its exceptional properties which include corrosion resistance, surface finish and durability. This material exists in various forms that are listed below:

- Sheets and Plates

- Bars and Rods

- Tubes and Pipes

- Wires

- Foils

- Coils

- Angles and Channels

- Fittings and Flanges

- Mesh and Screens

Material Standards

For every material, there is a certain criteria and standard it needs to maintain based on which it is considered authentic for any industrial usage. Likewise, 409 SS grade is also linked with several international and regional standards that are mentioned below:

ASTM International

- ASTM A240/A240M

- ASTM A268/A268M

- ASTM A276

- ASTM A240

EN Standards

- EN 10088-2

- EN 10296-2

- EN 10088-1

ISO Standards

- ISO 15510

- ISO 6935-2

- ISO 6929

JIS Standards

- JIS G4304

- JIS G4303

What is 409 Stainless Steel Used for: Applications and Parts

409 grade SS due to its unique set of properties is readily available for wide range of application. Some of them are mentioned as follow [13] [14]:

- Exhaust Systems

- Heat Shields

- Heat Exchangers

- Chemical Processing Equipment

- Food Processing Equipment

- Building Cladding

- Decorative Elements

- Fabrication Parts

YouTube link:

https://www.youtube.com/watch?v=bCGf79jStQ8&pp=ygUgNDA5IHN0YWlubGVzcyBzdGVlbCBhcHBsaWNhdGlvbmQ%3D

Figure 2: Applications of 409 SS grade

Composition and Microstructure

Below is the chemical composition along with the microstructure analysis of 409 grade stainless steel:

Chemical Composition

The chemical composition of 409 stainless steel includes the following elements:

Table 1: Chemical Composition

|

Elements |

Percentage composition |

|

Carbon |

0.08% |

|

Manganese |

1.0% |

|

Phosphorus |

0.040% |

|

Sulfur |

0.030% |

|

Silicon |

1.0% |

|

Chromium |

10.5-11.75% |

|

Titanium |

0.5-0.75% |

Furthermore, there is a list below of elements along with the crucial role they play for 409 grade SS:

Table 2: Role of elements

|

Element |

Role |

|

Carbon |

Maintain the ferritic structure and prevents carbide formation. |

|

Manganese |

Enhances the corrosion resistance |

|

Phosphorus |

Prevent the formation of brittle phases |

|

Sulfur |

Maintain the ferritic structure and prevents the formation of brittle phases. |

|

Silicon: |

Enhances the corrosion resistance and maintain the ferritic structure |

|

Chromium |

Provides the primary corrosion resistance |

|

Titanium |

Stabilizes the ferritic structure |

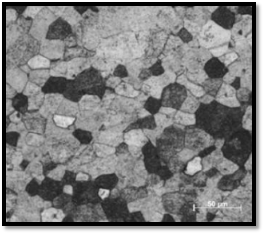

Microstructure of 409 Stainless Steel

409 SS grade normally show a ferritic microstructure, categorized by a BCC crystal lattice. It contains mainly ferrite phases with minor amounts of other phases including carbides as well as sigma phases distributed throughout the matrix.

Figure 3: Microstructure of 409 ferritic SS

In the above figure, the dark regions signify the ferritic phase, on the other hand the lighter areas imply the occurrence of carbides and other phases. The microstructure of 409 SS plays a pivotal role in influencing its mechanical as well as physical properties.

Impact of Microstructure on Properties

- Ferrite phases offer better strength as well as hardness, rather low ductility when compared with austenitic SS. Moreover, carbides and other phases presence impact grain boundary cohesion.

- It contributes to making 409 SS ferromagnetic in nature. The allocation and size of carbides can influence thermal and electrical conductivity,

- It also impacts mechanical behavior under specific conditions.

Corrosion Resistance of 409 Stainless Steel

409 SS grade is famous for its resistant to corrosion under moderate conditions. It has a protective oxide layer made of chromium which protects this steel from aggressive environmental conditions and once this layer is damaged, it can self-heal due to adequate amount of oxygen present and sufficient available time. Below is a brief description of its behavior under certain types of corrosion:

Atmospheric Corrosion

Metal exposed to a certain atmosphere mainly natural without any liquid immersion leads to atmospheric corrosion. 409 SS has capability to resist against such corrosion. Moreover, this corrosion has a strong influence on various environmental factors including temperature, pollutants, humidity etc.

Aqueous Corrosion

Metals that are mostly in contact with water or any other aqueous solution leads to corrosion that is referred as aqueous corrosion. In this case, 409 SS resistance capability varies based on the following factors:

- Water composition

- Temperature

- pH levels

High-Temperature Corrosion

When metal is exposed to elevated temperature with other aggressive conditions such as oxygen presence and other reactive gases, it leads to high temperature corrosion. 409 SS offer better resistance against oxidation at roughly around 675°C. Moreover, it has the ability to maintain structural integrity in applications that includes regular heating and cooling cycles.

Specific chemical environments

409 grade SS react differently under specific chemical environments which is given below:

Figure 4: Specific chemical environments

Mechanical Properties of 409 Stainless Steel

Mechanical properties are considered the backbone of material structural integrity. Here we discuss these properties in terms of 409 grade SS:

Tensile Strength

409 SS demonstrates a tensile strength between 380 to 550 MPa which indicates its capability to withstand pulling forces.

Yield Strength

This steel grade show yield strength of 170-280 MPa showing its ability to bear mechanical stresses without deforming permanently.

Elongation

409 SS grade elongation usually lies between 20 to 25% in a 50 mm gauge length showing the amount of deformation it can bear before fracture.

Hardness

This grade of stainless steel 409 comprises of hardness that usually lies between 160 to 200 HB.

Impact Strength

409 SS grade comprises of moderate impact strength and can vary according to certain conditions showing its capability to absorb energy during sudden impact.

Fatigue Strength

It usually constitutes of moderate fatigue strength demonstrating its capability to withstand cyclic load especially in engine component.

Creep Strength

409 grade SS has comparatively lower creep strength than other grades which shows its inability to withstand aggressive conditions (high temperature with constant stress).

Significance of Each Mechanical Property for Engineering Applications

Below is the significance of each property for engineering applications:

Table 3: Property along with significance

|

Property |

Significance |

|

Tensile strength |

Designing components encountered by tension forces, i.e., structural elements and fasteners |

|

Yield Strength |

Components that require predictable elastic behavior i.e., springs |

|

Elongation |

Applications requiring forming and shaping processes. |

|

Hardness |

Pivotal for selecting materials for abrasive environments. |

|

Impact Strength |

Parts subjected to impact or shock loading e.g. vehicle bumpers. |

|

Fatigue Strength |

Components subjected to repeated stress cycles e.g. engine components. |

|

Creep Strength |

Parts operating at elevated temperatures for extended periods, such as furnaces. |

Physical Properties of 409 Stainless Steel

Physical properties are essential when dealing with design consideration. However, there are certain factors which has a strong influence on 409 SS physical properties i.e., temperature, composition, microstructure along with manufacturing processes and treatments. Yet Below are the major properties associated with 409 grade SS:

Density

409 SS grade has a density of around 7.7 to 7.9 g/cm³ which is essential for weight and volume calculation eventually affecting its structural stability.

Thermal Conductivity

This material has a low thermal conductivity of about 25-30 W/m·K making them less suitable for heat resistant applications compared to other stainless steel.

Electrical Conductivity

Its BCC crystalline structure makes it a poor electricity conductor. Hence, suitable for only nonconductive applications.

Thermal Expansion

It has a moderate coefficient of thermal expansion with variation of temperature which is 10.4 x 10^-6 /°C approximately.

Magnetic Properties

409 stainless steel demonstrates ferromagnetic properties. Hence, it is magnetic in nature which is typically higher than austenitic stainless steels.

Manufacturing and Process of 409 Stainless Steel

409 SS can be processed via different fabrication techniques due to its unique set of properties and ease of fabrication. Below are some of the most common processes that this material goes through:

Forming

The material is applicable for a variety of manufacturing processes because it is formable through various conventional techniques. Hence, it can cold form using bending, roll forming as well as drawing. Apart from that, it can also be hot formed under controlled temperature to avoid distortion as well as excess of grain growth.

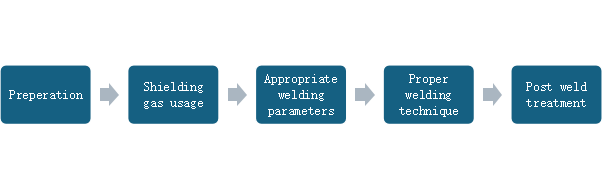

MIG Welding 409 Stainless Steel

409 grades can also be welded via MIG welding technique keeping in mind the protocols and necessary measures to be taken for accurate welding. Following steps are involved in MIG welding:

Machining

This grade is difficult to machine comparatively because of its properties like high hardness as well as work hardening tendency. However, under expert operator and proper care, various machining operations can be done such as turning, milling, drilling and grinding respectively.

Heat Treatment

This material is usually non heat treatable due to its ferritic crystalline nature yet it can be annealed usually at a temperature lying between 790 to 900°C that is followed by furnace or air cooling.

Summarize Differences Between of 409 Stainless Steel Properties

Below is a brief comparison among 409 SS and 304 SS grade:

Table 4: 409 SS vs 304 SS grade

|

Property |

409 SS grade |

304 SS grade |

|

Cr |

10.5% to 11.75% |

18% to 20% |

|

Ni |

0.5% |

8% to 10% |

|

Corrosion Resistance |

Good |

Excellent |

|

Magnetic Properties |

Magnetic |

Non-magnetic |

|

Weldability |

Good |

Difficult |

|

Cost |

Lower |

Higher |

|

Applications |

farm equipment, structural supports |

Chemical processing, industrial equipment |

Advantages and Disadvantages of 409 Stainless Steel

Here are some pros and cons of 409 grade SS:

Advantages

- Corrosion resistant

- Cost effective

- High temperature resistant

- Formability

- weldability

Disadvantages

- Machinability

- Lower ductility

- Lack in aggressive conditions

Design Considerations for 409 Stainless Steel CNC Parts

Below are some basic requirement criteria for design consideration for 409 SS CNC parts:

SS 409 Equivalent Material

While choosing an equivalent for 409 SS grade CNC parts, first you need to understand that what set of properties it possesses that includes physical, thermal as well as mechanical properties. Apart from that, its behavior under corrosive and high temperature environment. Beside there are many alternatives of 409 SS yet it depends entirely on the application demand.

409 Stainless Steel Rust

AS we know that 409 SS grade shows moderate resistant against corrosion therefore necessary measures should be taken to avoid degradation of material. This can be done by applying protective coatings and paint etc. which will enhance the shelf life of CNC parts.

Mechanical Requirements

This is another major requirement that needs to be tailored while designing a CNC part, but it totally depends on the application. This can be done by analyzing how much load the application must bear and understand as well as interpreting the performance criteria of the respective parts meeting the required specifications.

- Sulfuric Acid- Limited resistance to sulfuric acid, especially at higher concentrations or temperatures.

- Nitric Acid-moderate resistance to nitric acid, particularly in dilute concentrations.

- Chloride Solutions- can be prone to pitting and crevice corrosion when exposed to chloride solutions.

- Alkaline Environments-can handle mild conditions, but its resistance decreases in highly concentrated alkaline solutions.

- Organic Acids-exhibits good resistance to organic acids like acetic acid, making it suitable for use in certain food processing and chemical applications.

Corrosion Resistance Requirements

Corrosion is another factor that needs to be kept in mind while considering the design of your CNC parts. This can be done by examining the environmental conditions in which the required application could be exposed. Is 409 SS capable to withstand those environment other wise additional measures should be taken by applying protective coating or upgrading the grade of stainless steel.

Processing Considerations

Machining 409 SS grade is difficult due to adequate amount of hardness therefore in this situation appropriate cutting tools and machining parameters should be taken while considering design of CNC parts to optimize efficiency of machining.

Cost-Effectiveness

For designing CNC parts, the overall cost needs to be considered from manufacturing to finishing as well as additional treatments that involves protective coatings. As far as 409 SS is concerned, its major advantage is its affordable cost as compared to other stainless-steel grades.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

A2-70 Stainless Steel vs 18-8: Choosing the Right Material

A2-70 Stainless Steel vs 18-8: Choosing the Right Material