15 Things You Didn't Know About Brass Alloy

May 10,2024

May 10,2024

Brass, a distinct and versatile metal alloy primarily composed of copper and zinc, has played a pivotal role in manufacturing and technological advancements across numerous industries. Its unique properties, including superb malleability, corrosion resistance, and excellent electrical conductivity, make it an invaluable material in various applications—from decorative art to cutting-edge aerospace components. In this article, we delve into the lesser-known facts about brass alloy, exploring its fundamental aspects, unexpected uses, and its future in innovative technologies. Here at Tuofa CNC Machining, we leverage our expertise to harness the full potential of brass in our precision fabrication processes.

The Difference Between Brass,Copper,Bronze

Here is a table that provides a comparative overview of brass, copper, and bronze, detailing their compositions, color, weight (density), and relative cost. These factors are essential for understanding their suitability for different applications:

|

Metal |

Composition |

Color |

Density (g/cm³) |

Relative Cost |

|

Copper |

Pure Copper (Cu) |

Reddish-orange |

8.96 |

High |

|

Brass |

Copper (Cu) and Zinc (Zn); sometimes with lead (Pb) or tin (Sn) for machinability or strength |

Yellowish, varies with zinc content |

8.4 - 8.7 |

Moderate |

|

Bronze |

Copper (Cu) and Tin (Sn); may include elements like aluminum (Al), nickel (Ni), or phosphorus (P) for additional properties |

Dark brown, muted gold |

7.4 - 8.9 |

Moderate to High |

How to Identify Antique Brass Alloys

Identifying antique brass alloys involves a few key steps that can help you determine the composition and age of the piece,These steps can help you discern genuine antique brass from replicas or other metals.

Magnet Test

Brass is non-magnetic, so use a magnet to check if it attracts. If it does, the item might not be pure brass.

Color Inspection

Genuine brass should have a bright golden appearance, although antique pieces may appear darker or have a greenish patina due to oxidation.

Sound Test:Strike the brass gently

It should produce a deep ringing sound rather than a dull thud, which is characteristic of brass's acoustic properties.

Weight and Feel

Brass is heavier than many other metals that might be used to imitate it. It should feel solid and substantial.

Check for Markings

Look for any manufacturer’s marks, inscriptions, or hallmarks which can provide clues about the origin and age.

Professional Evaluation

For a definitive identification, consider consulting with an expert in antique metals or a professional appraiser who can provide insights based on advanced testing and experience.

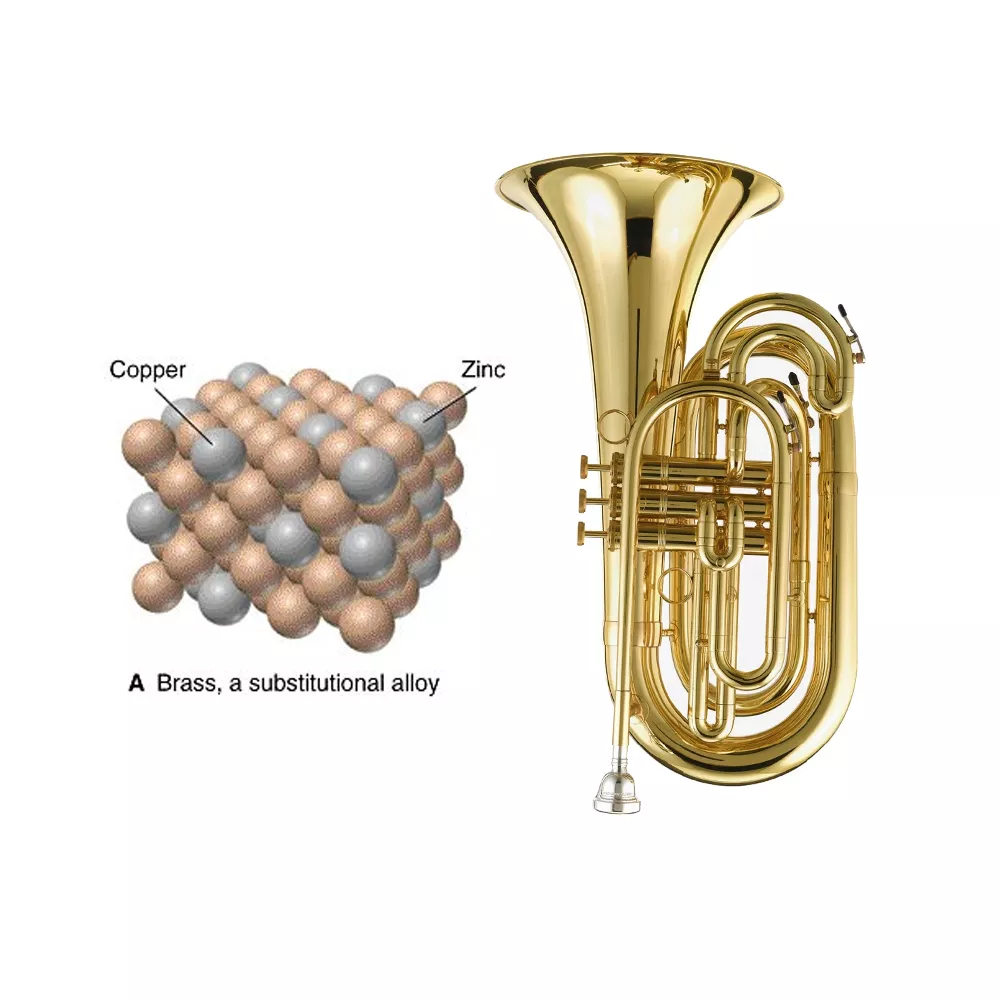

Brass Made The Trumpet,Trombone,Tuba

Brass is the primary material used to make musical instruments such as the trumpet, trombone, and tuba. These instruments are part of the brass family, where sound is produced by the musician vibrating their lips on the mouthpiece. Brass enhances the rich, resonant tones that characterize these instruments, making them popular in various musical settings like orchestras, jazz bands, and marching bands.

Brass as Currency

Brass has historically served as a practical currency material, especially during times when precious metals like gold were scarce. During World War II, several nations minted brass coins due to metal shortages. In West Africa, brass and copper manillas were used extensively as a versatile form of currency for transactions ranging from everyday purchases to bridal dowries and burial rites, highlighting its economic and cultural significance.

Among The Earliest Metals Used by Humans

Brass, an alloy of copper and zinc, ranks among the earliest metals utilized by humans. Its history traces back thousands of years, with evidence of its use in decorative items, coins, and tools. The alloy's durability, workability, and antimicrobial properties have made it a valuable material across various cultures and eras. Brass's distinctive golden hue also contributed to its popularity in art and ornaments throughout history.

It Can Kill Many Bacteria

Brass, predominantly composed of copper, possesses inherent antimicrobial properties. This copper-based alloy can effectively prevent the spread of bacteria and even destroy germs on contact. This characteristic makes brass especially valuable in environments where hygiene is paramount, such as in medical facilities and public spaces, contributing to safer, more sanitary surfaces and reducing the risk of bacterial transmission.

It Can Present Many Different Colors

Brass alloy, known for its versatility, can exhibit a wide range of colors depending on its composition and finish. Typically, brass appears as a bright golden yellow, but variations can include red, brown, or green hues, especially when altered by patination processes. These color variations make brass a popular choice in decorative arts, jewelry, and architectural features, allowing for aesthetic flexibility in design and craftsmanship.

A Very Environmentally Friendly Metal

Brass alloy is exceptionally environmentally friendly, primarily due to its infinite recyclability. Being a copper-based alloy, brass retains its chemical and physical properties through multiple recycling processes. This sustainable trait offers significant environmental and economic benefits, reducing the need for new raw materials and minimizing waste. Brass's enduring qualities make it an ideal choice for eco-conscious manufacturing and applications.

Ranked Third in Industrial Use

Brass alloy is ranked third in terms of industrial usage, following closely behind steel and aluminum. This widespread use is attributed to brass's excellent machinability, corrosion resistance, and electrical conductivity. Its versatility makes it indispensable in various sectors including plumbing, electronics, and decorative applications. Brass's unique properties ensure its continued relevance and demand across multiple industries.

Brass Alloy Vehicle Radiators

Brass alloy is commonly used in vehicle radiators due to its excellent heat conductivity and resistance to corrosion. This combination makes brass ideal for managing the high temperatures and cooling requirements of automotive engines. Additionally, brass radiators are durable and reliable, providing long-lasting performance in harsh operating conditions. Their effectiveness in heat transfer significantly enhances engine efficiency and longevity.

Ammunition Casings

Brass alloy is extensively used for ammunition casings due to its resilience, corrosion resistance, and ability to expand and contract under extreme pressures. This makes brass ideal for creating reliable, durable casings that can withstand the rigors of firing while ensuring a tight seal in the firearm's chamber. Its machinability also allows for precise fabrication, which is crucial for the performance and safety of ammunition.

Maintain Brass Alloy Jewelry

To maintain brass alloy jewelry, keep it dry and store it in a cool, airtight container to prevent tarnishing. Regularly clean it with a mixture of lemon juice and baking soda or mild soap and water. Use a soft cloth to gently polish the surface. Avoid contact with harsh chemicals such as chlorine and ammonia. For added protection, apply a thin layer of clear nail polish to prevent oxidation.

Shipbuilding Components

In shipbuilding, brass alloy is crucial for manufacturing components like propellers and navigational instruments due to its exceptional resistance to biofouling and corrosion. These properties ensure that ships maintain high functionality and efficiency over extended periods. Brass's durability and anti-corrosive nature make it an ideal choice for critical marine applications, where reliability under harsh sea conditions is paramount.

The Most Popular Types of Brass

Today, over 60 varieties of brass are available, each offering unique properties for specific applications. If you're considering brass for your next project, understanding the distinctions among the most popular types can help you select the best option based on your specific requirements.

|

Type of Brass |

Composition |

Key Characteristics |

|

Admiralty Brass |

70% Copper, 30% Zinc, 1% Tin |

Dezincification-resistant, durable |

|

Muntz Metal |

60% Copper, 40% Zinc, traces of Iron |

High corrosion resistance, strong, hard, and rigid |

|

Aluminum Brass |

76% Copper, 22% Zinc, 2% Aluminum |

Extremely corrosion-resistant, especially to seawater |

|

Manganese Brass |

70% Copper, 29% Zinc, 1.3% Manganese |

Improved fatigue strength, excellent resistance to wear and tear |

Advantages of Brass in CNC Machining

At Tuofa CNC Machining, we specialize in the precise fabrication of brass components. Brass alloys are extensively used in CNC (Computer Numerical Control) machining due to their excellent machinability and consistent performance in precision fabrication. Their unique properties make brass particularly suitable for complex and detailed CNC machining tasks, which require high levels of accuracy and repeatability. Here's a closer look at why brass is a preferred material in CNC machining processes:

Exceptional Machinability

Brass is known for its superior machinability among metals. It allows for high-speed machining while maintaining precision, which is critical for producing intricate designs and fine details without excessive tool wear.

Good Surface Finish

Brass can achieve a smooth surface finish directly from the machine, reducing the need for additional finishing processes. This quality is highly beneficial in creating decorative as well as functional components.

Strength and Durability

Despite being easy to machine, brass is a durable alloy with good strength, ensuring that the machined parts can withstand operational stresses and have a long service life.

Corrosion Resistance

Brass's resistance to corrosion and environmental degradation makes it an excellent choice for components exposed to moisture and other corrosive elements, such as plumbing fixtures and marine hardware.

Low Friction and Non-Sparking

These properties make brass ideal for applications requiring non-sparking tools and components that operate under frictional conditions, such as fittings and fixtures in explosive environments.

Conclusion

The versatility and enduring importance of brass in modern industries cannot be overstated. As we continue to explore and expand its applications, Tuofa CNC Machining remains at the forefront, offering our expertise in brass alloy products. We invite industry professionals and mechanical designers to connect with us and discover how our capabilities can help achieve your project objectives.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Understanding Metal Melting Points: A Comprehensive Guide for Manufacturing Professionals

Understanding Metal Melting Points: A Comprehensive Guide for Manufacturing Professionals