Exploring Ultem 1000: A Comprehensive Guide

Jun 01,2024

Jun 01,2024

Ultem 1000 is a polyetherimide PEI which is high performance material fall in the category of thermoplastic materials. Polyetherimide PEI is well known for its inherent flame retardation, dielectric strength, mechanical strength, and stiffness that's why has caused the industrial revolution from medical to aerospace. Its resistance to heat makes it favorable for applications that require dimensional stability. In this article, you will find interesting knowledge of the characteristics and applications of polyetherimide Ultem 1000.

What is Ultem 1000?

Polyetherimide PEI resin also known as ULTEM™ Resin 1000 is thermoplastic with high performance. ULTEM™ Resin 1000 has an amorphous crystal structure. Ultem 1000 is a glass transparent material with a transition temperature of 217°C. Polyetherimide Ultem 1000 is known as a high-performance polymer because it has excellent flexural strength, dielectric strength, impact resistance mechanical strength, and stiffness. ULTEM™ Resin 1000 can bear temperatures up to 340°C so has high resistance to temperature. Polyetherimide PEI also has steam sterilization and hydrolysis resistance.

Polyetherimide ultem 1000.

YouTube video explaining Ultem in one minute.

https://www.youtube.com/watch?v=oJbmDRBB1ZQ&pp=ygUKdWx0ZW0gMTAwMA%3D%3D

What are the forms of ultem material?

To meet different manufacturing needs, Ultem1000 is available in the following forms.

- Resin pellets.

- Films

- Rods

Ultem 1000 rods and sheets.

Key Properties of Ultem 1000

Ultem 1000 is a high-performance polymer due to excellent mechanical and chemical properties and has vast applications in the electronics, medical, and aerospace industries. Some of its characteristics are discussed below.

High Heat Resistance

Ultem 1000 shows high resistance to temperatures up to 340 °C and can withstand high temperatures if exposed for a short time. ULTEM™ Resin 1000 properties make it suitable to be used in applications like electrical insulators where thermal stability is crucial.

Excellent Strength and Stiffness

Ultem 1000, due to high tensile strength and stiffness, are called high-performance polymers. Polyetherimide Ultem 1000 can be used in load-bearing applications like structural components.

Outstanding Chemical Resistance

Polyetherimide Ultem 1000 shows high resistance to chemical environments including hydrocarbons, alcohols, and acids. This high resistance to chemicals makes it suitable for applications like laboratory instruments and chemical processing equipment.

Electrical Insulation

low dissipation factor and high dielectric strength make Ultem 1000 suitable for electrical insulators. Ultem 1000 due to these properties is used in electrical components like circuit boards and insulators.

Benefits and Drawbacks of Using Polyetherimide Ultem 1000

The advantages and disadvantages of Ultem 1000 are discussed below in table.

|

Benefits |

Drawbacks |

|

Withstands high temperatures. |

More costly than other plastics. |

|

Superior mechanical performance. |

Hard to machine; needs special tools. |

|

Resists a wide range of chemicals. |

Can be brittle; may crack under impact. |

|

Excellent electrical insulating properties. |

Not as widely available. |

|

Stable over various conditions. |

Needs specific processing conditions. |

|

Naturally flame retardant. |

Higher density than some plastics. |

Thermal Stability

Polyetherimide ultem 1000 has high thermal stability making it suitable for applications where components must bear high temperatures. ULTEM™ Resin 1000 also has the property of inherently flame retardation.

Factors Affecting Thermal Stability

Thermal stability of the Ultem 1000 depends on the factors like bonding type, molecular structure, and thermal conductivity of the Ultem 1000 chemical structure.

Molecular structure

Polyetherimide Ultem 1000 has the molecular structure of imide linkages and rigid aromatic rings contributing to its high thermal stability. These bonds are strong and resist thermal degradation.

Bonding type

Ultem polyetherimide PEI has a covalent bond which is the strongest bond and can't transfer heat easily. These reasons make it difficult for Ultem 1000 to thermally degrade.

Thermal conductivity

The ability of Ultem 1000 not to conduct heat helps polyetherimide Ultem 1000 to retain its structural integrity at high temperatures.

Measurement Techniques

There are two techniques used to test the thermal integrity of the material which are given below.

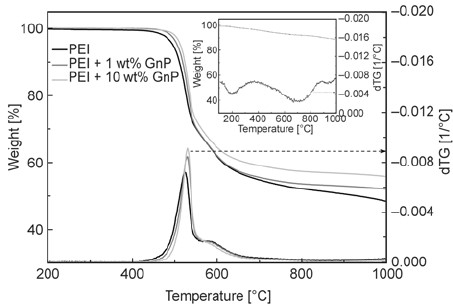

Thermogravimetric Analysis (TGA)

TGA allows the formation of thermal degradation and decomposition temperature profiles. TGA helps us to study thermal stress vs stability of polyetherimide PEI. TGA measures weight loss of material concerning temperature increases.

TGA curve of pure ultem 1000 and composites of ultem1000.

Differential Scanning Calorimetry (DSC)

DSC helps us to measure the glass transition temperature and melting point of Ultem 1000. DSC makes the profile of heating and cooling of material as heat flows inside and outside of a material.

DSC curve of pure ultem 1000 and its composites.

Chemical Resistance

ULTEM™ Resin 1000 is one of the best chemical resistive high-performance polymers. Which show excellent corrosion resistance to acids, hydrocarbons, bases, and alcohols. The effect of chemical composition on chemical resistivity is discussed below.

Impact of Chemical Composition

The presence of an aromatic ring gives flexibility and stability to Ultem 1000 against a chemical environment. Imide linkage resists hydrolysis, chemical reactivity, and oxidation. Ether linkages provide flexibility and resistance to reactivity to nucleophiles and bases. That’s why ether linkages add additional stability to the chemical environment.

Resistance to acids

Ultem shows excellent resistance to acids such as.

- Acetic acid with concentrations of almost 10% and 50%.

- Chromic acid with a concentration of almost 10%.

- Hydrochloric acid with concentrations of almost 10% and 50%.

- Nitric acid with concentrations of almost 10% and 50%.

- Phosphoric acid with concentrations of almost 10%, 50%, and even 100%.

- Sulfuric acid with concentrations of almost 10% and 50%.

Resistance to bases

Ultem shows excellent resistance to acids such as.

- Ammonium hydroxide concentrations of 10%, 50%, and even 100%.

- Sodium hydroxide concentration of 10% and 50% almost.

- 10% calcium hydroxide

Resistance to solvents

Polyetherimide Ultem 1000 does not show good resistance to some solvents like toluene, benzene, and xylene but shows good resistance to solvents like:

- Glycerin

- Mineral oils

- Acetone concentrations of 10% and 50% almost.

- Ethyl ether

- Naptha

- Ethylene glycol

Applications in Chemical Industries

Chemical processing: Applications include Piping, Fittings, valves, pumps, reaction vessels, and tanks.

Pharmaceuticals: Applications include blenders, mixers, and filling machines.

Testing Methods

Immersion tests: The Ultem 1000 is immersed in the chemical in its resistance must be checked. This immersion is done for a specific period. The sample is prepared according to ASTM standards. The change in physical and mechanical properties are accessed in that chemical.

Physical Properties

Physical properties let us know which material is suitable for which application. Physical properties include melting point, density, hardness, tensile strength, ductility, and thermal expansion of material.

Role of Physical Properties in Material Selection

For material selection analysis of physical properties is very crucial. Studying physical properties will let you know if the material can face the environmental conditions of that application or not. Some physical properties of Ultem 1000 are given below that would help you in selecting Ultem 1000.

|

Property |

Value |

|

Density |

1.27 g/cm³ |

|

Melting Point |

217-223°C (glass transition temperature) |

|

Tensile Strength |

110 MPa |

|

Ductility (Elongation at break) |

60-80% |

|

Thermal Expansion |

5.4 x 10⁻⁵ 1/°C |

Influence of Environmental Conditions

Temperature: Ultem 100 is a strong high-performance polymer with high thermal stability up to a temperature of 340 Temperature above this causes degradation of the polymer. Polyetherimide PEI is inherently flame retardant.

Humidity: Almost all polymers absorb water in humid environments and deteriorate. Ultem 1000 is a strong polymer with the chemical composition of imide linkage and aromatic rings. This chemical composition makes Ultem 1000 a good moisture handler. Long exposure of Ultem 1000 to moisture and humidity may start deteriorating material in its service life.

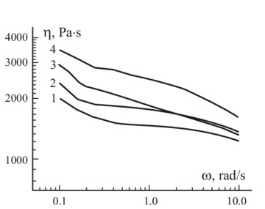

Mechanical Behavior

Ultem 1000 is a high-performance thermoplastic that has high machinal strength, stiffness, impact resistance, and thermal stability at high temperatures. The tensile test stress-strain relationships are discussed below of polyetherimide Ultem 1000.

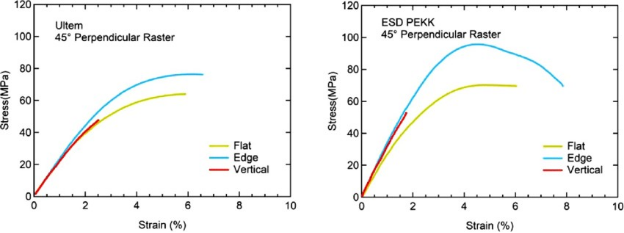

Stress-Strain Relationship

A tensile test on ultem 1000 is performed and a plotted stress-strain diagram.

The graph shows a comparison between the stress-strain curve of ultem vs ESD PEKK.

The mechanical properties of Ultem 1000 are given below:

|

Property |

Value |

|

Tensile Strength (Stress) |

110 MPa |

|

Elongation at Break (Strain) |

60-80% |

|

Elastic Modulus (Elasticity) |

3.2 GPa |

|

Yield Stress (Plasticity) |

100 MPa |

Fatigue and Fracture Mechanics

Fatigue cycles: Ultem 1000 can withstand more than 1 million cycles at 10Mpa.

Fracture points: The threshold after which the crack will be generated is called the fracture point for Ultem 1000 it is 1.0 - 1.2 MPa√m.

Testing Mechanical Behavior

The mechanical behavior of polyetherimide Ultem 1000 can be accessed through tests like:

Tensile tests: These help us to assess the strength, UTS, plasticity, and elasticity of the polymer by making a stress-strain cure.

Impact tests: This test helps us to judge the impact resistance of the Ultem 1000 by ensuring the impact toughness of the Ultem 1000.

Hardness tests: The indenter is pressed on the surface with different forces. Rockwell and Vickers hardness tests are performed to measure the hardness of Ultem 1000.

Electrical Properties

Electric properties indicate if the material can pass electrons through it or not. The electrical properties include resistivity, conductivity, and dielectric strength which are discussed below for ultem1000.

Conductivity and Resistivity

The electric conductivity value of Ultem 1000 is very low making it an excellent insulator with electric resistivity of > 10¹⁴ Ω·cm.

Dielectric Strength

High voltage resistance refers to the ability of material to resist electrical breakdown even at high voltages. Ultem 1000 has very good voltage resistance. It can show resistance to electrical breakdown up to 15KV voltage. Ultem 1000 can withstand high electrical stresses without getting broken so has high dielectric strength which is 830 volts per mil noted in the literature.

Applications in Electronics

- Semiconductors

- Insulators

CNC Machining for Ultem 1000

CNC machining is a modern and expensive technique of cutting material. High accuracy and precision are the key to CNC machining which make its price worth it. CNC machining allows high dimensional precision, excellent surface finish, and fast fabrication of parts and assemblies of bigger components.

Ultem 1000 Machinability

High-tech parts of Ultem 1000 which require precise cutting, high dimensional stability, and smooth surface finish are always preferred to be machined from CNC machining. CNC machining of Ultem 1000 allows fast production of components.

Machining Tips

- Always do CNC machining from trusted professionals.

- Use a fast metal cutter for Ultem 1000 cutting due to its high strength and stiffness.

- Continuous removal of scrab to prevent surface scratches and internal stresses.

- Annealing after machine to remove internal stresses.

YouTube video explaining key tips for CNC machining of plastics.

https://www.youtube.com/watch?v=1HKLwTv2GLU&pp=ygUbY25jIG1hY2hpbmluZyBvZiB1bHRlbSAxMDAw

Ultem 1000 in Engineering and Design

Ultem is a CNC machined and designed into the respected component shape for high performance during its service life. This high-performance polymer due to its high mechanical properties, chemical properties, and thermal properties is used in different industries. Some of the industries and their respective components where Ultem 1000 is used are listed below.

Aerospace Industry

With high impact resistance, fatigue resistance, and thermal resistance ultem 1000 is an appropriate material to use in some aerospace components as listed below.

- Electrical Connectors

- Insulation Components

- Structural Parts

Medical Industry

Resistance to Sterilization, resistance to chemicals, and the nontoxic nature of Ultem 1000 make it the best choice for medical components like:

- Surgical Instruments

- Diagnostic Equipment

- Dental Tools

Automotive Industry

High mechanical properties, thermal stability, and impact resistance make Ultem 1000 best candidates for automotive industry applications like:

- Under-the-Hood Components

- Lighting Systems

- Sensor Housings

Electronics Industry

The thermal stability and inheritance flame retardation of Ultem 1000 makes it the best candidate for applications like:

- Printed Circuit Boards (PCBs)

- Connectors and Sockets

- Enclosures and Housings

PEI ultem 1000 component.

Considerations for Designers

Ease of assembly and snap-fit designs of Ultem 1000 is possible due to its good ductility and plasticity. While easy mating of Ultem 1000 with other metals is possible due to its uniform thermal expansion.

Best Practices for Ultem 1010 Plastic

A high-performance polymer known as Ultem 1010 is thermoplastic. The best practice for this polymer includes.

- Annealing after machining to remove internal stresses.

- While machining use water-soluble coolants which are non-aromatic for a better surface finish.

- Use a hard metal cutting tool for machining for precise cutting.

- Prevent highly humid environments.

- Sanding and polishing types of post-processing must be done for a better surface finish and less internal stress.

Ultem 1010 vs 9085

The table below compares between properties of 1010 vs 9085 Ultem.

|

Property |

Ultem 1010 |

Ultem 9085 |

|

Heat Resistance |

Higher heat resistance |

Lower than 1010 |

|

Mechanical Strength |

Higher mechanical strength |

Moderate mechanical strength |

|

Chemical Resistance |

Excellent |

Good |

|

Flame Retardancy |

Naturally flame retardant |

Naturally flame retardant |

|

Typical Applications |

Medical devices, aerospace, automotive |

Aerospace, Transportation |

|

Processing Ease |

More challenging to process |

Easier to process |

YouTube video explaining the difference between 1010 vs 9085 Ultem.

https://www.youtube.com/watch?v=etVcSk3Zheg&pp=ygUJdWx0ZW0gMTAw

Ultem 1000 vs 2300

The table below compares between properties of 1010 vs 2300Ultem.

|

Property |

Ultem 1000 |

Ultem 2300 |

|

Glass Fiber Content |

No glass fiber |

30% glass fiber |

|

Mechanical Strength |

High |

Higher due to glass fiber |

|

Stiffness |

Excellent |

Superior due to reinforcement |

|

Density |

Lower |

Higher |

|

Dimensional Stability |

High |

Very high |

|

Typical Applications |

Electrical components, insulators |

Structural components, high-stress environments |

Ultem 1010 vs 1000

The table below compares between properties of 1010 vs 1000 Ultem.

|

Property |

Ultem 1010 |

Ultem 1000 |

|

Heat Resistance |

Higher heat resistance |

High heat resistance |

|

Mechanical Strength |

Higher mechanical strength |

Excellent |

|

Chemical Resistance |

Excellent |

Excellent |

|

Biocompatibility |

Suitable for medical applications |

Not specified |

|

Processing Ease |

More challenging |

Easier |

|

Typical Applications |

Medical, aerospace, automotive |

Electrical components, industrial applications |

Conclusion

It is concluded that Ultem 1000 is one of the best high-performance plastics with exceptional characteristics. Ultem1000 has revolutionized the material in industries like aerospace, medical, and electrical.

FAQ

How does Ultem 1000 perform in terms of chemical resistance compared to other plastics?

Yes! Ultem 1000 is one of the best-known plastics for its chemical resistivity against acid, hydrocarbons, bases, and alcohols. Although Ultem 1000 is the best chemical resistive plastic but still doesn't show good chemical resistance to solvents like xylene, benzene, and toluene.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What is the Melting Point of Copper?

What is the Melting Point of Copper?