Rough Milling vs. Finish Milling: Key Differences and Practices

Mar 05,2025

Mar 05,2025

We have been using CNC machines for more than a century. With time, advancements have been made in CNC machines, and now they can perform multiple operations at a time while keeping the tight tolerance of the object. Milling is one of the operations performed by CNC machines. Milling is further divided into two types, i.e. rough and finish milling. The material removal rate is the main difference between the milling types. This article briefly explores the milling process and provides detailed information about rough and finish milling and their differences.

What is Milling?

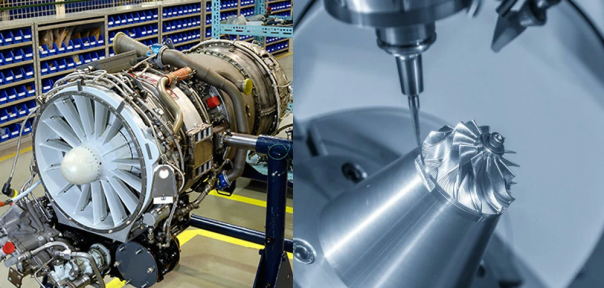

Milling is a manufacturing operation used to manufacture components of desired shapes by cutting excessive material. Special milling tools are used for the machining of different parts. This operation is used in every industry from aerospace to the medical and electronics industry.

Types of Milling: Rough vs. Finish

There are two types of milling, i.e. rough and finish, based on the material removal rate. The detailed difference between rough and finish milling is provided in this article.

Understanding Rough Milling: The First Step in CNC Machining

We should understand the difference between both types, like when we should choose which operation. This section addresses some aspects of rough milling.

What is Rough Milling?

Rough milling is the primary process in manufacturing a workpiece. The material removal rate is very high in this way. Surface finish and dimensional accuracy are not the main concerns.

Key Process of Rough Milling

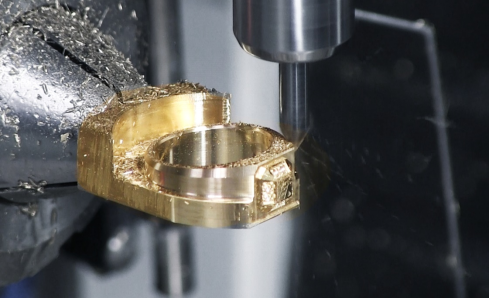

In rough milling, robust tools and aggressive cutting speeds are used to remove large amounts of material quickly. The material of the workpiece is removed till its final desired look. In the end, only finishing is required.

Tooling for Rough Milling

Robust and high-performance cutting tools are required. These tools generally have a lower number of flutes and optimized geometry to remove chips of the material. Tools are formed of Tungsten or high-speed steel.

What is Finish Milling? Perfecting the Final Product

Once the workpiece is converted into the desired shape, the final looks are provided in this milling type.

The Purpose of Finish Milling

The purpose of finish milling is to provide the desired surface finish, tolerances, etc., to the product. The errors from the rough milling are removed in this operation. That is the finishing operation on the manufacturing floor.

Achieving Precision and Accuracy

Finish milling provides the exact precision and accuracy required for the product according to the application. Every surface flaw is removed in this step.

Improving Surface Quality

Rough milling provides a very rough surface finish to the product, which is not acceptable for the applications. Finish milling does the job of improving surface quality.

Key Process of Finish Milling

This milling requires ultimate care to get the desired dimension without any surface defects. The cutting speed and feed rate are optimized to attain the required results.

Common Applications for Finish Milling

Finish milling has many applications, but the following two are the main applications.

High-Precision Components

High-precision components of critical industries, such as the aerospace industry, are manufactured using finish milling.

Complex Geometries and Tight Tolerances

The components have complex geometries and tight tolerances and are used in medical implants and the electronics industry. Finishing milling is used for this application.

What Is The Difference Between Rough And Finish Milling?

This section is a detailed review of the differences between rough and finish milling.

Material Removal Rate (MRR)

The material removal rate (MRR) is the basic difference between rough and finish milling.

Rough Milling - Maximizing Material Removal

The material removal rate is high in this milling. For instance, in the case of making a nut, a square workpiece is cut into a nut shape. For this purpose, a large amount of material is cut from the workpiece.

Finish Milling - Slower but More Controlled MRR

Since the workpiece is already in the desired shape of the product, only finishing steps are required. That is why a controlled MRR is used to achieve maximum accuracy and tight tolerance.

How MRR Affects Cost and Time Efficiency

MRR has a direct relation with cost and time efficiency. Due to the high MRR in rough milling, it provides higher time efficiency. Finish milling is a slower process due to controlled MRR.

Feed Rate and Depth of Cut

The feed rate and depth of cutting the surface finish greatly; that's why these factors must be considered in both milling types.

Feed Rate for Rough Milling

Since, in the rough milling, a bulk material is removed from the workpiece, a higher feed rate is used to maximize the material removal rate.

Feed Rate for Finish Milling

In finish milling, we have to remove material in a very controlled manner to achieve maximum accuracy and tight tolerance. That's why the feed rate is lower in finish milling.

Depth of Cut Differences

Rough Milling

- Deeper cuts to remove the material in bulk from the workpiece

Finish Milling

- Shallow cuts to carefully remove the material from the workpiece to attain a superior surface finish and precision

Surface Finish Quality

Both milling types provide different levels of surface finish quality due to differences in cutting tools, cutting parameters, etc.

The Rough Surface from Milling

Because it uses high cutting speeds and robust tools, bulk material is removed from the surface of the workpiece. This aggressive cutting results in a very rough surface finish.

Achieving a Mirror Finish with Precision Tools

A rough surface finish is not required in any case, which is why it is improved using finish milling. A controlled and careful material removal results in achieving a mirror finish using precision tools.

Functions Of Rough Face And Mirror Finish Surfaces

- For enhanced bonding between the surface and coating, a rough surfaceis required

- To get an aesthetic appearance or for functional uses, i.e. reduced friction or enhanced wear resistance, a mirror surface finish is required

Dimensional Accuracy and Tolerance

Accuracy and tolerance depend on the milling tools, cutting speeds and material removal rate during the milling of a component.

Tolerances in Rough Milling

The main focus is material removal in the rough milling; that's why the tolerances are looser in this milling.

Tolerances in Finish Milling

Tight and required tolerances are produced using optimized cutting parameters, appropriate tools and controlled MRR.

Managing Tolerance Variations Across Phases

To manage tolerance variations across phases, it is important to leave enough material during rough milling so that to achieve the desired tolerance, we do not need excessive machining.

When to Choose Rough Milling Over Finish Milling

The following are the conditions when rough milling is preferable over finish milling.

Assessing Material and Geometry

First, you need to assess the material and geometry of the component before selecting a milling operation.

Harder Materials and Complex Shapes

For harder materials and complex geometries, rough milling is ideal when bulk material is required.

Cost Considerations in Early-Stage Machining

It becomes cost-effective because large amounts of material are removed from the workpiece.

Speed and Efficiency Needs

Speed and efficiency are the second requirement after assessing the material and geometry of the workpiece.

Bulk Material Removal for Cheaper Manufacturing

Rough milling can remove large amounts of material from the workpiece in less time, which makes it a cost-effective manufacturing process.

Best for Prototype or Pre-Production Phases

For pre-production and prototyping, the main concern is efficient material removal. That's why, in this case, rough milling is preferable.

Examples from Industries

The following are the main industries where rough milling is used extensively.

Aerospace Industry Needs for Rough Milling

In the aerospace industry, making components such as aircraft frame components, etc., rough milling is used.

Automotive and Heavy Industry Rough Milling Uses

In the automotive and heavy industry, parts like chassis components are manufactured using rough milling. This milling operation provides higher-volume productions with good efficiency.

When to Choose Finish Milling Over Rough Milling

The following are the conditions when you should choose to finish milling.

Critical Accuracy and Precision Requirements

To get durability, accuracy and precision are required.

The Need for Fine Tolerances in Final Components

Finish milling is the final manufacturing step in the milling. To get fine tolerance, the material is removed in a very controlled manner in finish milling.

Adjusting for Tool Wear and Surface Imperfections

Finish milling removes all surface imperfections so that issues like tool wear do not occur.

Applications Requiring Smooth Surface Finish

Smooth surface ensures the durability of the product that's every industry requires smooth surface.

Medical Devices and High-Performance Components

Any surface flaw is unacceptable in industries where safety criteria are high, which is why smooth surface is used in medical and high-performance components.

Jewelry, Mold Making, and CNC Finishing

There are many reasons why a smooth surface finish is important in the following properties.

Jewelry

- Aesthetic appearance

- Engraving and Detailing

- Comfort and durability

Mold Making

- Better material flow

- Reduced post-processing

- Releasing the product

CNC Finishing

- Precision and Accuracy

- Reduced friction and wear

- Aesthetic appeal

Part Geometry Considerations

Complex Geometries and Their Impact on Tool Selection

Complex geometries have a great impact on tool selection. To achieve the desired precision, finish milling is ideal.

Post-Machining Process for High-Precision Parts

After the final finishing, we often do not need post-processing. The reason is that all the dimensional issues are resolved in the finish milling.

Tooling Considerations for Rough vs. Finish Milling

Tools are different for rough and finish milling; that's why choosing an appropriate tool according to the requirement is important.

Choosing the Right Tool for Rough Milling

If an inappropriate tool is selected for rough milling, it will result in tool wear and a reduction in the product's integrity.

Tool Geometry and Durability

Tool geometry and durability have a direct relationship with each other. Tools for rough milling helix angle, which increases cutting efficiency by making chip evacuation easier.

Carbide and High-Speed Steel for Rough Milling Tools

Tools for rough milling must be made of carbide or high-speed steel to prevent tool wear issues.

Choosing the Right Tool for Finish Milling

Now, we will study the right tools to finish milling.

Fine Cutters and Tool Geometry for Precision

To maintain accuracy and tight tolerance, tools for finish milling should have fine cutters and optimized geometry.

Importance of Coatings to Extend Tool Life

Coatings on the tools prevent tool wear and friction, which results in increased tool life.

Impact of Tool Wear on Both Processes

Tools can be prone to tool wear in the milling types, reducing the tools' life.

Tool Life Management in Rough Milling

The chances of tool wear are higher in rough milling as compared to finish milling. This issue is managed by regular maintenance and the replacement of tools on time.

Managing Tool Deflection in Finish Milling

You should optimize the cutting parameters to prevent tool deflection in finish milling.

Tips for Optimizing Milling Practices

The following tips can help optimize milling practices.

Optimizing Rough Milling for Speed and Efficiency

First, we will see optimizing rough milling for speed and efficiency.

Maximizing Material Removal in Short Time Frames

Use aggressive cutting parameters and durable tools for maximizing material removal in short time frames.

How to Handle Tool Wear in High-Material-Removal Situations

Regular maintenance and replacement of tools are crucial for handling tool wear in rough milling.

Optimizing Finish Milling for Precision and Quality

To get precision and quality in the products, it is important to optimize finish milling as well.

Minimizing Surface Defects

Minimizing the surface defects is the ultimate goal in finish milling. It can be obtained by using fine cutters and precise tools.

Adjusting Cutting Parameters for Surface Integrity

Adjust the cutting parameters, such as feed rate, cutting speed, etc., to enhance the surface integrity.

Conclusion:

We have gone through a detailed difference analysis between rough and finish milling along with a brief overview of milling operation. We can conclude now that rough milling is the process we use to start for bulk material removal, and finish milling is the final operation in manufacturing. Rough milling results in a rough surface due to aggressive cutting operations, while finish milling provides a very smooth surface finish.

FAQ

How is a roughing end mill capable of taking more load when compared to a finish end mill?

Fewer flutes and stronger geometries of the rough milling tools make them able to withstand higher loads.

Can I use the same end mill for rough and finish milling?

No, you should not use an end mill for the finish milling because each tool is designed for a different purpose.

Why do rough milling tools have fewer flutes than finish milling tools?

For better chip evacuation and higher material removal rate (MRR).

What materials are best suited for rough milling?

Steel and titanium are harder materials, these are well suited for rough milling because of their ability to withstand aggressive cutting parameters.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Face Milling vs End Milling for Specific Materials: Which Tool Works Best?

Face Milling vs End Milling for Specific Materials: Which Tool Works Best?