Face Milling vs End Milling for Specific Materials: Which Tool Works Best?

Mar 10,2025

Mar 10,2025

You see different complex shapes in your daily life. The parts include turbine blades, engine parts, surgical tools, etc. All these tools are manufactured using specified cutting tools or machines. Multiple operations are performed to get precise dimensions of the parts. Although many machines or tools are used in manufacturing industries, this article will only explore the two tools, i.e. face milling and end milling, and the difference between them in terms of working principles, applications, etc.

What is Milling?

Milling is a cutting process used to make complex and custom-designed parts with great efficiency and tight tolerance. In this process, we use multiple rotary cutters to remove the material. Milling is a versatile tool for many materials, including plastics and composites, and is used in many industries, such as aerospace and medicine.

Other Types of Milling Processes

This article mainly focuses on two types of milling processes, i.e. face milling and end milling, but other types of milling processes are:

- Peripheral Milling

- Slot Milling

- Plunge Milling

- Shell End Milling

Face Milling VS Shell End Milling

Face Milling

- Face milling uses large-diameter cutting tools and is used for flat surfaces

- Ideal for large surfaces

Shell End Milling

- Uses a smaller but versatile tool

- Ideal for small producing complex shapes

Peripheral Milling Vs Face Milling

Peripheral milling involves cutting along the edges of the workpiece, which makes it easier to make slots and contours. Face milling is used mostly for flat surfaces.

Why Does Choosing the Right Tool for Different Materials Matter?

It is important to choose the right tool for the respective materials because a wrong selection of tools will cost you the loss of both materials' integrity and wear and tear on tools. Ultimately, this will cause financial loss.

Impact of Material Type on Milling Choices

The nature of the workpiece material affects the selection of cutting tools.

- If the workpiece material is soft, such as Al, use sharp tools and fast cutting speeds

- If the material is hard, such as Ti and its alloys, use robust tools and slower cutting speeds

Key Considerations When Choosing Milling Tools

It is always wise to consider important factors to prevent loss of materials' integrity and wear and tear on the tool. Before choosing a milling tool, you should consider the following factors:

- Material Hardness

- Parts' Geometry

- Desired Surface Finish

- Machining Speed

What is Face Milling?

This section presents valuable information regarding face milling.

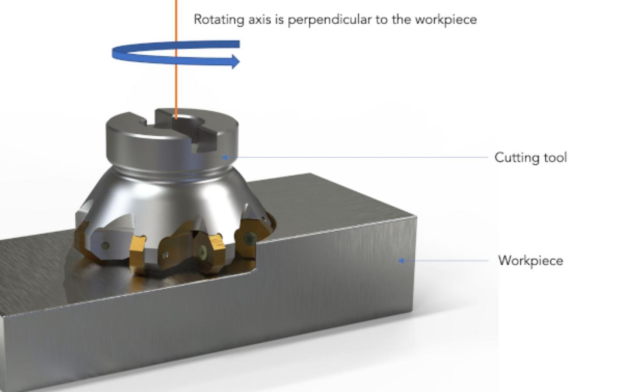

Overview of Face Milling Process

In the face milling process, a tool consisting of multiple teeth is used to produce the desired products. The diameter of the tool is large. The combination of teeth and a large diameter provides high material removal rates, producing large and flat surfaces.

How Face Milling Works for Different Materials

As we mentioned earlier, the type of materials decides how a specific milling operation will work. We change parameters such as cutting speed, types of cutting tools, etc., for different materials in face-end milling.

Face Milling for Soft Materials

When you are dealing with soft materials, you should use sharp-edge cutting tools and faster cutting speeds. These parameters ensure an enhanced surface finish, hence the durability of the component.

Face Milling for Hard Materials

For hard materials, you can use robust tools and slower cutting speeds to prevent wear and tear issues for cutting tools.

What is End Milling?

This section of the article provides insights into the end milling process.

Overview of the End Milling Process

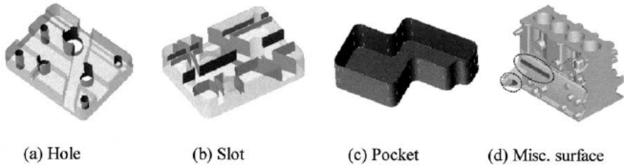

End milling is cutting a workpiece using a rotating cutter that moves parallel to the workpiece. The cutter contains cutting edges on both ends and sides. It is a versatile process which provides both rough and finishing operations. We can make slots, pockets, complex geometries, etc., using the end milling process.

How End Milling Works for Different Materials

We just change the parameters according to the materials as we change in the face milling process.

End Milling for Soft Materials

For soft materials like Al, use high cutting speed and sharp edges.

End Milling for Hard Materials

For hard materials like titanium, use robust tools and slower cutting speeds.

What Is the Difference Between Face Milling and End Milling?

In this section, we will analyze some major differences between face milling and end milling.

Cutting Action and Tool Geometry

Face Milling

The large diameter of the cutter contains multiple teeth. The cutter moves in the direction of the workpiece movement.

End Milling

Small cutting tool with cutting edges on both ends and sides.

Surface Finish Quality for Different Materials

A good surface finish ensures a product's durability. If a product is rough, the friction during the application will be high, which ultimately reduces the efficiency of that product.

It produces high-quality surface finish products, while end milling can produce detailed and precise finishes.

Surface Finish in Face Milling

Since the material removal rate is higher in face milling, the surface finish is higher in surface milling.

Surface Finish in End Milling

The material removal rate is less compared to face milling. So, the surface finish is relatively lower than the face milling.

Tool Engagement and Efficiency

The following table presents a summary of tool engagement and efficiency of both face milling and end milling processes.

|

Feature |

Face Milling |

End Milling |

|

Cutting Direction |

Perpendicular to the surface |

Parallel to the surface |

|

Material Removal |

Removes material from the large surface |

Used for slotting and contouring |

|

Tool Design |

Large diameter with multiple inserts |

Small diameter and cutting edges |

|

Surface Finish |

Face milling produces a smoother and flatter surface finish |

Sometimes, tools leave machining marks on the workpiece |

|

Efficiency |

Efficient for large surface area |

Specialised in deep cuts and detailed work |

This table shows a brief overview of surface finish-related aspects.

Face Milling vs End Milling for Different Materials

In this world, many materials serve multiple purposes in real-life applications. Some of the most used materials are Al and its alloys, steel and its alloys, Titanium and its alloys, etc. We will present some brief information related to how to end and face milling operations used for these materials. As we mentioned earlier, we use one of the processes according to the material's nature. So, it is important to choose the cutting method wisely for maximum outcomes.

Face Milling vs End Milling Performance on Aluminum Alloys

The common Al alloys are 6061 and 7075 and can be easily machined using both face and end milling processes. For detailed work on small workpieces of Al alloys, the end milling process is preferred. It means, ultimately, the selection depends on the material removal rate and cutting efficiency, etc.

Cutting Efficiency & Material Removal Rate

For a higher material rate (MRR), you can choose the face milling process. As a result, you will get a rough surface finish. If the surface finish is a concern, you should choose the end milling process. Although it's a slower process, it is more efficient.

Surface Finish Comparison

For Al alloys, end milling provides a smoother surface finish because of cutting-edge engagement; the cutting tool encounters the workpiece gradually, with a smaller tool diameter. It often employs the climb milling principle. That's why we use it for making slots, holes, etc.

In the case of face milling, the cutting tool encounters the workpiece instantaneously, which is why it provides a rough surface finish.

Tool Wear in Face Milling vs End Milling for Aluminum

7075 aluminium causes more tool wear in End Milling due to its hardness, which is why we do not prefer end milling for harder materials. Whereas Face Milling can reduce wear through optimized feed rates and cutting depths.

Face Milling vs End Milling for Steel and Stainless Steel

Stainless steel is a harder material; that's why we need some robust tools to machine it. We prefer that you use the face-milling process. Further information is given below in this section.

Face Milling vs End Milling on Steel Alloys

AISI 1045 and 4140 stainless steel alloys are used in common applications such as kitchen accessories, etc. First, for roughing surfaces, you can use face milling for detailed work and cuts, and end milling is preferable.

Cutting Force Comparison

4140 steel generates higher cutting forces and heat, making Face Milling more suitable for roughing large areas, whereas End Milling is better for detailed, intricate cuts.

Surface Quality in Face Milling vs End Milling

You know that end milling is a specialized cutting method for detailed work and intricate cuts on the workpieces. That's why we prefer end milling on steel alloys like AISI 1045 and 4140 for a superior surface finish, especially for detailed features, while Face Milling generally results in a rougher finish due to the large cutting area.

Hard Materials Milling: Titanium Alloys

Titanium is the most powerful material in terms of every property. Its excellent properties, such as the highest tensile strength, good hardness and excellent corrosion and oxidation resistance even at high temperatures, make it suitable for applications in the aerospace industry.

Face Milling vs End Milling on Titanium Alloys

Titanium alloys like Ti-6Al-4V alloy are very hard and difficult to machine. In challenging conditions, face milling will do its job, while for intricate cuts on the surface, you can use end milling.

Cutting Speed and Tool Selection

Slower cutting speeds and larger diameters will prevent tool wear issues in the case of face milling.

For precise cutting of small workpieces, you should use end milling.

Efficiency of Face Milling vs End Milling on Titanium

Face milling is an efficient tool if the Ti workpiece is larger in terms of surface area, while end milling shows its efficiency in small parts.

Material Removal Rate (MRR) in Titanium Milling

Face Milling generally has a higher MRR for large titanium surfaces, while End Milling is more efficient for the precision cutting of small, detailed features, offering lower MRR but better accuracy.

When to Use Face Milling vs End Milling for Applications

This section is important for selecting a cutting method according to the applications.

Face Milling for Large, Flat Surfaces

If the target area where you must remove the material is larger, you will need a high material removal rate. In this case, choose the face milling process.

End Milling for Detailed Features and Edges

The end milling process is, although a slower process in terms of cutting speed and material removal rate, efficient in providing detailed features and edges on the surfaces. You can use it for stainless steel and titanium alloys, etc., without any issue.

When to Combine Face Milling and End Milling

There are many applications, like mould cavities, where face milling and end milling are used in combination. Face milling generates rough surfaces, and end milling provides deeper and intricate cuts.

Optimizing Milling Processes for Material Type and Application

If you optimize milling processes according to respective material types and applications, it will enhance the efficiency of the process and the durability of the product.

Choosing the Best Tool Based on Material Properties

If the material is harder, choose robust tools and slower cutting rates. For softer materials like Al, choose sharp tools and fast speeds.

Adjusting Milling Parameters for Optimal Results

Use optimum cutting speed, feed rate and tool for a better surface finish and to enhance the durability of the product.

Cutting Speed and Feed Rate Considerations

Fast cutting speeds for softer materials and slower speeds for harder materials to prevent tool wear issues.

Depth of Cut and Tool Selection

Deeper cuts are for roughing the surface, and shallower cuts are for finishing if required.

Conclusion

This article summarises that both face milling and end milling operations are important in manufacturing industries. The selection between these processes is based on many factors like material removal rate, level of surface finish, intricate cuts, etc. These processes are used in making slots, pockets, structural parts, etc. These processes can be used in combination according to the requirements.

Frequently Asked Questions (FAQs)

Can face milling and end milling be combined for a single project?

Yes, we can use them combined for a single project. The real-life example is mould cavities in which we first use face milling for roughing the surface, and then we use end milling for finishing.

Greater wear on an end mill doing facing?

Yes, that's why an optimum selection of tools is required. When you use end mills for harder materials, you will face wear issues.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Riveting vs Welding: Join Sheet Metal Parts

Riveting vs Welding: Join Sheet Metal Parts