CNC Router vs Milling Machine: A Complete Comparison

Dec 13,2024

Dec 13,2024

CNC Router and CNC Milling machines are different versions of a CNC machine. These machines are useful in many industries to manufacture complex parts. You will have heard about these machines, but this article is a complete guide about these machines in which each factor related to these machines is discussed. A complete comparison between these machines is discussed in this article.

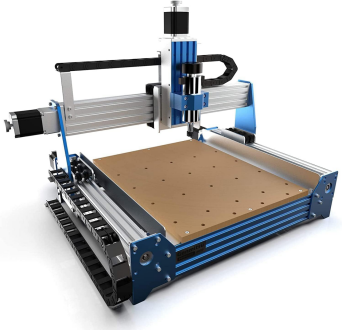

What Is a CNC Router?

This is a version of a CNC machine which is used to manufacture complex designed parts by cutting soft materials such as plastics etc. It cuts the workpiece in the same manner as the milling machine does but it is not as advanced as a milling machine. The following image is a CNC router:

CNC Router Basics

It is important to know the basics of any machine or component before using it to avoid further issues. The basics of a CNC router include it works through a CNC program, and an Automatic Tool Changing (ATC) feature is available in this version and used for softer materials only.

Key Features of CNC Routers

Key Features include:

- Computer Numerical Controlled (CNC) System

- Automatic Tool Changing (ATC) Mechanism

- Precise control over spindle motion due to moderate speed

- Easier Software

- Drilling or milling can be performed using a CNC Router

What is a CNC Router Used for

As we discussed earlier, it is used for manufacturing complex parts by cutting the softer materials i.e. wood. It is used in many industries because of its precision CNC machining.

- For engraving on the workpiece

- In prototyping

- In furniture making

- To make musical instruments

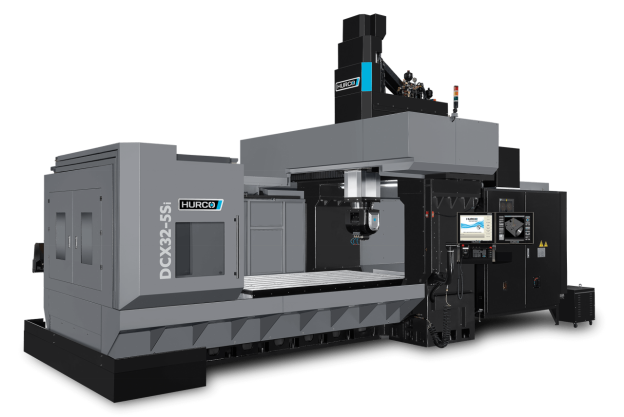

What Is a CNC Milling Machine?

It is a very advanced version of the CNC machine, as the following figure shows. CAD/CAM software is used to run a CNC milling machine and to control its tools. It is used for preparing complex parts of harder metals by the cutting process.

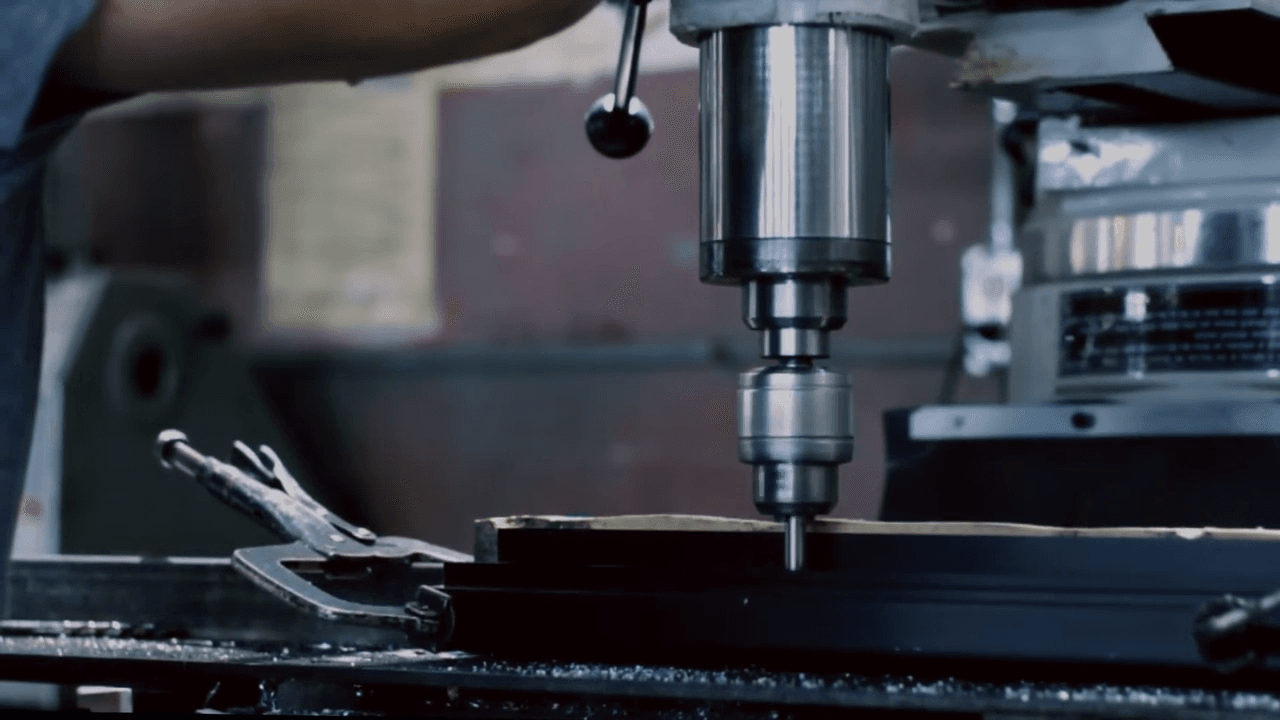

CNC Milling Basics

Its basics include it has multipoint cutting tools which a CNC program controls, the spindle is very quick and exerts a large force to machine the harder material parts and is used for precision engineering applications.

Key Features of CNC Mills

- Automatic tool-changing mechanism

- Can machine hard materials into complex structures

- High Precision and accuracy

What is CNC Milling Used for

You know it is a very advanced cutting machine, CNC milling services used where the standards are high such as in the aerospace industry, automotive, and medical devices. etc. for mass production and precision engineering.

Is Milling the Same as Routing?

CNC router is used to prepare parts of softer materials i.e. plastic while the milling is used to machine harder materials. So, they are not the same.

Can You use a CNC Router as a Mill?

No, because a CNC mill is used to machine hard materials such as stainless steel because of its high spindle speed which a CNC router does not have.

Differences Between CNC Routers vs CNC Milling Machine

One of the major differences between these techniques is the nature of the material of the workpiece, i.e. hard or soft. Other differences are briefly discussed below:

Materials Compatibility

If you have one of the following materials and want to choose the most appropriate CNC machine, then this section is for you.

Suppose you have a hard material such as Al, Stainless steel, Ti, Brass or Copper for your components. It means it requires high force to deform etc. then you should choose CNC milling.

If your components are of plastic material let’s say Acrylonitrile Butadiene or Poly Ether Ether Ketone (PEEK) or wood, they require lower forces than hard materials and moderate spindle speed that’s why, you should go for a CNC router.

You should have the idea before selecting a machining method or machine.

Machining Speed

Before the selection of the machine, you should know its specifications and machining speed is one of them. The machining speed is higher in CNC routers, that’s why they are used for softer materials.

Component Type

Milling components require high precision and tight tolerance such as a turbine blade, then CNC milling is an appropriate option.

Accuracy and Precision

If the material of your component is softer let’s say it is a plastic material and it requires accuracy and precision, then a CNC router will be a better option.

Cutting Area (Work Envelope)

If the cutting area is large, then choose a CNC router for better results and if it is smaller, then you should choose a CNC milling.

Tooling Options

CNC milling machines have generally more cutting tools, that’s why we call it a versatile machine.

Cutting Functions

The process of cutting is the same in both machines, but the materials are different. The function of the cutting in milling is related to the harder materials while in the case of a CNC router, the cutting is done to manufacture parts of softer materials.

Configurations

There are some criteria on which these machines are configured. If your part needs high precision, then choose a CNC milling machine. If your workpiece is softer, has a smaller working area and requires fast spindle speed then you should select a CNC router machine.

Software and Control Systems

- For CNC machining there are many software and Control Systems but the most used are Mach3 and Sinumerik respectively.

- Mach4 and Fanuc are the program and control systems respectively.

Ease of Use

A CNC router is easy to use because it is easy to control the spindle motion, and the software is easy as well. For CNC learning, it is an easy version.

Differences Charts for CNC Router and Milling Machine

Here is the summary of the above differences:

|

Technology |

CNC Milling |

CNC Router |

|

Materials Compatibility |

Hard materials i.e. stainless steel |

Soft materials i.e. plastics |

|

Machining Speed |

Slower |

Moderate |

|

Component Type |

Highly precise and tight tolerance i.e. landing gears |

Plastic joints, seals etc. |

|

Accuracy and Precision |

Good for harder materials |

Good for plastic materials |

|

Cutting Area |

Smaller |

Larger |

|

Tooling Options |

More |

Less |

|

Cutting Functions |

More |

Less |

|

Software |

Mach3 |

Mach4 |

|

Ease of use |

High-level skills |

Easier to learn |

Advantages and Disadvantages of Using a CNC Router

Advantages of Using a CNC Router

- The best cutting machine for those materials which require very high forces to deform such as stainless steel.

- High-precision engineering components

- Efficient mass production without errors

- Fast production rate

- Small workpieces are machined easily

Disadvantages of Using a CNC Router

- High material waste

- A highly skilled operator is required

- Not a suitable option for smaller productions

Advantages and Disadvantages of a CNC Milling Machine

Advantages of CNC Milling Machine

- Used to machine softer materials i.e. plastics

- Best prototyping

- Larger working area workpieces are machined

- Control over spindle motion is higher due to moderate cutting speed

Disadvantages of CNC Milling Machine

- Noise of CNC router machining is very high

- Cannot machine hard materials

When Should You Choose a CNC Router?

Now it is time to have a look at when we should choose a CNC router over a CNC Milling machine and for which materials.

Best Use Cases for CNC Routers

The best use cases for CNC routers are when the workpiece material is soft and has a larger working area. If you have to make a prototype, then it would be a good case as well.

Ideal Materials for CNC Routers

The spindle speed is fast but it exerts lower forces so, the ideal material is a softer material such as plastic or wood etc.

When Should You Choose a CNC Milling Machine?

This section is about when choosing a CNC milling machine is best:

Best Use Cases for CNC Mills

When the case is about high-precision CNC machining, and reliability, to meet aerospace safety standards, then choose a CNC mill.

Ideal Materials for CNC Milling Machines

The ideal materials are Aluminum, Stainless Steel, and Titanium.

Comparing CNC Routers and Mills: Speed, Power, and Rigidity

This section is about how much a CNC mill is different in terms of speed, power and rigidity than CNC routers.

Machining Speed

The machining speed is higher in milling machines which is the reason behind its use for hard materials and producing desired shapes parts efficiently.

Power Requirements

The power requirements and consumption in CNC milling are higher than in CNC routers because to cut a hard material i.e. titanium, a very high and powerful spindle speed is required.

Rigidity and Stability

The rigidity and stability of a machine are all about how it behaves during the machining of the components. A CNC milling machine is very stable and rigid that’s it remains stable while machining the hard materials.

CNC Router vs Milling Machine: Cost Comparison

This section addresses the difference in costs related to these machines:

Initial Investment and Operating Costs

Initial and operating costs both are higher for CNC milling because the machine is expensive, and energy requirements are higher during the machining.

Maintenance Costs

The maintenance costs are almost the same for both machines in general.

Common Applications of CNC Routers and Milling Machines

This section is addressing the applications of both processes:

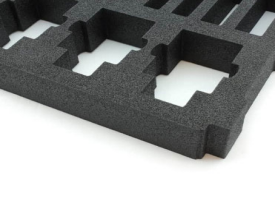

CNC Router Applications

It is used in making:

Furniture

Cabinet Components

Sign Making

Engraving

Prototyping

Foam cutting

CNC Milling Machine Applications

In the aerospace industry, it is used to make turbine blades components, landing gears etc.

CNC milling machines are used to manufacture engine blocks, brackets etc. in the automotive industry.

Orthopedics and surgical tools are manufactured through CNC milling machines.

Similarities Between CNC Routers and Milling Machines

The working procedure is the same as both work through a CNC program i.e. CAD/CAM programming, both are CNC cutting machines.

Can You Use Both CNC Routers and Milling Machines in One Workshop?

Yes, of course, you can use both if you manufacture both harder and softer materials parts. You can read here the benefits of using both.

Benefits of Having Both

The CNC mill will prepare parts of harder materials like engine blocks of the cars, while the CNC router will be used in making a dashboard trim panel of the cars. Ultimately these machines would increase the production rate, save time and increase the profits.

Workflow Integration

Workflow integration is the same for both machines except for the material of the workpiece.

How Tuofa CNC Machining Can Assist with Your CNC Projects

The following are the areas in Toufa CNC machining company that would assist you in your projects:

CNC Machining Services for Routers and Mills

First, if you are working on your projects and you need prototypes, come to us irrespective of the material because we both have CNC Mills and CNC Routers. These CNC machines are advanced, and the operators are more skilful.

Custom CNC Solutions

your specific manufacturing alterations in the designs are possible through the custom CNC solutions we offer.

Frequently Asked Questions (FAQ) for CNC Router and CNC Mill

Which Is Better for Woodworking, a CNC Router or a CNC Mill?

CNC router will be a good option for woodworking because CNC router is specially designed for softer materials.

Can a CNC Router Be Used for Metal?

No, because it is not designed for the hard materials. The spindle speed is moderate and does not give enough force which can deform a metal. Using a cutting tool of a CNC router on the machining of a metal will damage the tool, so it is not wise to use a CNC router for metals.

What Materials Can a CNC Router Cut?

The softer materials are possible to machine very efficiently using a CNC router because it is designed in such a way it exerts a lower force to cut the workpiece. These materials include plastic and wood.

Can a CNC Milling Machine Cut Wood?

Yes, it is very easy to cut wood, but it is not wise because a milling process can damage the structural integrity of the softer materials.

Can a CNC Router Replace a CNC Mill or Vice Versa?

No, it is not possible because both machines are designed for different materials.

What Is the Average Speed Difference Between a CNC Router and a CNC Mill?

CNC milling machines have 2 to 3 times faster speed than the CNC routers.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

30 Best CNC Router Projects for Beginners in 2025

30 Best CNC Router Projects for Beginners in 2025