CNC Machine vs Laser Cutter: Which Is Right for You?

Mar 04,2025

Mar 04,2025

CNC and Laser Cutter; both are cutting machines used in manufacturing industries. You will find these cutting tools in sectors which have to meet higher safety standards. These industries include aerospace, medical, automotive, electronics etc. You will find many important points related to these two machines in this article. This article is easy and comprehensive for better understanding.

So, let's start then:

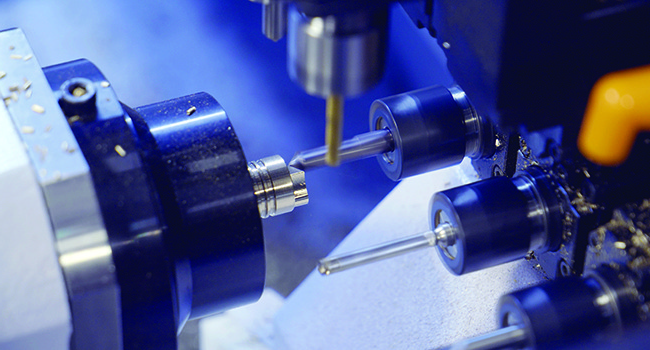

What Is a CNC Machine?

We will start by defining a CNC machine first because it was invented before a Laser machine. A CNC (Computer Numerical Control) machine is a cutting machine used to make components of desired shapes by removing excessive material. It is an automated machine equipped with an automatic tool changing (ATC) feature. This machine was invented in the 1940s to make precise components for the aerospace field.

Common Applications of CNC Machines

CNC machines are used in aerospace, automotive and woodworking. You can make components such as engine blocks, aircraft fittings, nuts bolts etc.

Materials Compatible with CNC Machines

It's a versatile machine. You can use CNC machining for any material such as plastics, metals and composites. It is difficult to machine ceramic materials on this machine because ceramic materials are brittle.

Types of CNC Machines

Some common types of CNC machines include:

- CNC Milling: When you are supposed to be cutting and drilling, use this machine

- CNC Turning: Use this CNC machine for cylindrical parts

- CNC Milling & Turning: Used for complex shapes and parts

What Is a Laser Cutter?

As the name shows, a laser cutter uses a highly ionized laser beam to cut a material. It's a fast-cutting tool used to produce intricate parts with high precision, accuracy and tight tolerances.

Introduction to Laser Cutting Technology

We will introduce laser cutting technology in this technology, we focus a laser beam on the respective material which melts or vaporizes the excessive material. This technology is highly efficient because it is controlled by a computer, which means the chances of errors are quite low.

Common Applications for Laser Cutters

The common applications of Laser Cutters are given below:

- To create detailed designs on the materials i.e. custom jewellery, custom signage and electronic components

- Used in prototyping and small-scale production

Materials Compatible with Laser Cutting

A laser cutting tool is not as versatile as a CNC machine. It is limited to many materials such as Ti, composites etc. But it is used to cut wood, acrylic, and leather efficiently. It is not compatible with thick and reflective materials.

Types of Laser Cutters

There are many laser cutters available on the market, but the following are the most common:

Crystal Laser

- Composition includes Neodymium doped yttrium ortho vanadate

- The wavelength of the beam is small which means higher intensity, so it is used for thick materials

CO2 Laser

- The most common cutting tool

- Laser is composed of CO2 gas

- Used for many materials because of the balance between power and precision

Nd: YAG laser cutters

- Low power cutting tools

- Used for skin treatment

A newly invented laser cutter is a direct diode laser. It is a lesser-known tool.

Advantages and Disadvantages of CNC Machines and Laser Cutters

This section presents a brief discussion of the pros and cons of CNC machines and Laser Cutters.

CNC Machines: Pros and Cons

Pros

- You will find it is the most efficient cutting tool because it can run 24 hours with minimal supervision due to the ATC feature.

- You can use it for mass production.

- It is a cost-effective cutting tool because post-CNC-machining is much less compared to other conventional machines.

- Since labor is not involved in CNC machining, so chances of human error and injuries are very lower.

Cons

- Initial installation costs are high as compared to any cutting machine

- Its maintenance is relatively very complex

- CNC programming is a bit difficult and takes time to understand

Laser Cutters: Pros and Cons

Pros

- Precision and surface finish of the cuts is higher than any cutting tool

- It is so versatile in terms of cutting materials that it can even cut ceramics with high precision

- There is no contact between the laser and the material, so the chances of contamination are 0 or very low

- Due to the narrow width, the material loss is quite low

Cons

These are the major disadvantages of using Laser Cutters:

- Can't cut thick materials

- Laser fumes are harmful

- High energy consumption

- Heat-Affected Zones (HAZs)

The Difference Between CNC Machine and Laser Cutter

This section of the article explores the major differences between a CNC machine and a Laser Cutter. A brief discussion is given below:

Cutting Method

CNC Machines

CNC machines operate using CNC programs. These programs are different for different operations such as G-code is used for milling operation only. These machines use automatic tool-changing (ATC) mechanisms for precision machining.

Laser Cutters

Laser cutters use lasers to cut materials to achieve the required shape or design of the component. The heat of that laser is so high it melts or vaporizes the material to remove it.

Precision and Accuracy

Both cutting tools are used for different purposes. If you have to machine larger parts with greater machining accuracy, you should use a CNC machine, because it is equipped with those tools which machine larger parts easily.

If your parts are small and require higher precision and detail, then a laser cutter is more suitable.

Speed: CNC vs Laser Cutting Speed Comparison

Cutting speed depends upon the thickness of the workpiece. If it is thin, then a laser cutter will be a faster tool while a CNC machine is more suitable for machining thick and larger workpieces with fast cutting speed.

Materials Compatibility

Both, CNC machines and Laser Cutter are versatile tools Which can machine multiple materials very easily. CNC machines are limited in the case of brittle materials such as ceramics and a laser cutter can't cut a thick workpiece.

Operational Costs

The primary costs are installation and maintenance costs. Operational costs include energy consumption, labour wages, workpiece material and post-machining costs. Operational costs are higher for CNC machines because of wear and tear on tools. Post-machining processing is relatively higher than laser cutter increasing further costs.

In the case of a laser cutter, energy consumption and initial costs are higher.

Learning Curve

CNC machines are technically more complex than laser cutters. If you are a beginner, it will be very easy to operate a laser cutter which means it's an easy cutting tool. To operate a CNC machine, the operator must be educated and know programming. It is equipped with multiple tools, so using an accurate tool becomes difficult in the beginning.

Material Wastage

You know that the working mechanism of a CNC machine is physical it uses different cutting tools which is why material waste is high in CNC machines.

A laser cutter uses a highly powered laser beam to cut the workpiece. The material waste is very low because only the focused area gets removed, so lower material waste makes it a more efficient cutting tool.

Safety Considerations

In a CNC machine, human involvement while cutting the workpieces is much less than it works using the Automatic Tool Changing (ATC) feature. This feature makes it a very safe cutting tool.

In the case of laser cutters, the chances of skin burns are higher.

Noise

CNC machines work physically, cutting tools make noise when they encounter workpieces and cut the material.

In the case of a laser cutter, the sound level is very low.

Tables for Difference Between CNC Machine and Laser Cutter

The following table is the summary of the above differences:

Feature |

CNC Machine |

Laser Cutter |

|

Material Thickness |

Thick materials |

Thin materials |

|

Precision |

High (3D) |

Extremely High (2D) |

|

Speed |

Moderate |

Fast (thin materials) |

|

Cost |

Higher maintenance |

Higher initial cost |

|

Ease of Use |

Requires expertise |

Beginner-friendly |

Post-Processing and Finishing

CNC machines often require more post-processing depending on the complexity of the cut. Laser cutters, while offering high precision, may require less finishing for certain materials. This difference can impact time and cost. In this section, we will briefly discuss the post-processing and finishing costs for both machines, i.e. the CNC machine and the Laser Cutter.

CNC Post-Processing and Finishing

Although a CNC machine is used to produce highly precise parts but still needs some post-processing operations to make parts able to be used in applications. The post-processing operations include polishing, sandblasting etc. These operations enhance the surface finish of the components which is important for durability.

Laser Cutting Post-Processing and Finishing

A laser cutter is a high-precision cutting tool which provides very sharp and clean cuts, reducing the post-machining operations.

CNC Cutting vs Laser Cutting: Which One to Choose?

The following are some factors i.e. parts complexity, materials compatibility etc. need to be understood before selecting a respective cutting tool.

Parts complexity

CNC machines excel in machining complex-shaped parts if your workpiece is 3D, a CNC machine can easily machine it.

A laser cutter is efficient only in 2D parts. So, that's the criteria for choosing between them based on complex parts.

CNC Cutting vs Laser Cutting for Metal

You can machine any metal using a CNC machine, but you can use a laser cutter only for thin and low-melting temperature metals.

Material Thickness: Which Machine Handles Thicker Materials Better?

A CNC machine can efficiently machine thick and larger workpieces. The reason behind its efficiency is the powerful cutting tools. These cutting tools easily cut the workpiece into desired shapes.

Laser cutters work best for thinner workpieces.

Technical Awareness: Which Requires More Expertise?

A CNC machine operates by CNC programming i.e. CAD/CAM systems. So, the operator must be very skilled in operating a CNC machine efficiently.

On the other hand, it is very easy to work using a laser cutter.

Factors to Consider Before Choosing CNC or Laser Cutting

In terms of applications, you should consider the following factors before you choose between a CNC machine and a laser cutter.

Project Scale

There are different types of project scales like some businessmen manufacturing parts at lower level and some at big stages. The cutting machines are selected based on the required production level. If you are supposed to be mass production and the parts are big or thick, it means you need fast production rates while maintaining the tight tolerances of the parts. In such a case, you should use a CNC machine.

Whether the parts or smaller and thin, laser cutters are more suitable.

Precision Requirements

If your workpiece is 2D, then laser cutters are best for detailed engravings or making intricacies.

For 3D parts, it is wise to use a CNC machine.

Budget: How Do Cost Factors Factor in Your Decision?

Initial costs for both tools are higher. The budget depends on the type of project. For a cheaper budget, a laser cutter is preferable because of its lower maintenance costs, compatible materials are cheaper etc. The budget for using a CNC machine must be high because of the compatible materials, maintenance costs etc.

Cost Analysis: CNC vs Laser Cutter for Metalworking

Some heavy metals are very difficult to machine because of poor machinability, these metals include high-carbon steel, stainless steel, titanium and its alloys etc. For metals of poor machinability, CNC machines are more cost-effective than laser cutters and vice versa.

Choosing the Right Machine for Your Metalworking Needs

The final decision of using the respective cutting tool is made based on applications.

Industry-Specific Applications: Automotive, Aerospace, and More

Metals are used in every industry I.e. aerospace, medical, electronics etc. For heavy-duty applications in the aerospace and automotive industries, you can easily machine heavy-duty metals with higher efficiency by using CNC machines. For electronics and medical industries, use laser cutters for efficient cuts.

Customization and Versatility: CNC vs Laser Cutting for Custom Parts

For custom parts, use CNC machines. To make intricate designs, you should use a laser cutter for durable results.

Long-Term Usage: Which Machine Provides Better Longevity?

Again, long-term usage depends on the type of application and surface finish. CNC machines provide durable results while laser cutters provide long-term precision in the dimensions.

Choose Tuofa China for Custom Metal and Plastic Parts

Toufa, a Chinese company is equipped with the most advanced CNC machines and laser cutters. You can come to us if you require highly precise components irrespective of the production level. We will deliver high-quality results in intricate, complex designs etc. in shorter times with the best rates in the market.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Rough Milling vs. Finish Milling: Key Differences and Practices

Rough Milling vs. Finish Milling: Key Differences and Practices