G Code and M Code: What is the Difference Between?

Aug 18,2023

Aug 18,2023

Introduction: Manufacturing industry uses CNC machining process for Turning, Milling, Boring, Facing, Cutting, Shearing and 3D profiling of raw material so that it can take shape of final product present on the engineering drawing of final product with proper surface finish. But language of CNC machine is G Code and M Code for various processes, thus it is impossible to accomplish these processes without learning Code Syntax, Format, Types, Application and Manufacturer compatibility.

What is M Code?

These codes have relation with CNC machines because main purpose of them are to control operation and switch CNC machines, so that miscellaneous operations are also in control of machinist without any hardware interaction. Otherwise it is difficult for machinist to perform the hardware and machine operation with physical instruction, thus m codecnc can help machinist to Stop coolant, Spindle on and Tool change with just one command syntax. Same codes are CNC machine language to help operator in routine maintenance without time delay, physical interference, job un-clamping and mistake chance.

What is G Code?

CNC g code have importance in field of machining operation because all machining operations are in control of g code programming syntax, even in use friendly interface of machine control panel topic of learn g codecncis part of machinist certification. Because if there comes complex or custom engineering part on machine table then friendly user interface cannot help machinist to perform the process due to unavailability of custom program in library of machine. Thus you have to take help of g code programming to convert drawing instructions into CNC machine operation performance code, so that machining process results are accurate, instant and reliable.

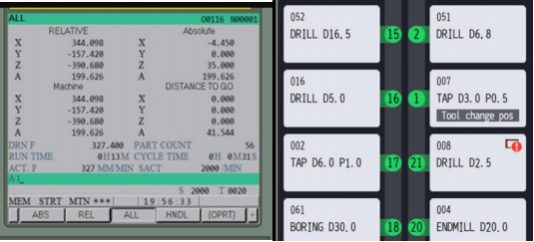

Figure.No.1 shows CNC user friendly interfaces.

Click herefor machining services and quotation for different types of custom machine parts with need of tolerances and flatness values.

CNC G and M Codes List

G and M Code are the language of machine with fixed syntax, thus you have to learn their style with fixed orientation so that variation from one machine to another does not occur in machining program logic. Table.No.1 and 2 describes list of codes with their purpose,

|

GCode |

Application |

|

G00 |

Motion inline |

|

G01 |

Motion at last speed |

|

G02 |

Motion at clockwise circular |

|

G03 |

Motion at counterclockwise circular |

|

G04 |

Stop for specified time |

|

G05 |

Non Modal Rapids |

|

G09 |

Motion for exact stop check |

|

G10 |

Programmable parameter |

|

G15 |

Polar to Cartesian Coordinates |

Table.No.1. G Code List.

|

MCode |

Application |

|

M00 |

To Stop Program |

|

M01 |

Gives option to stop |

|

M02 |

Terminate Program |

|

M03 |

Spindle in Clockwise |

|

M04 |

Spindle in Anti-clockwise |

|

M05 |

To Stop Spindle |

|

M06 |

To change Tool |

|

M08 |

To on Coolant |

For more information please visit on following YouTube links:

https://www.youtube.com/watch?v=5XihF05K4yM

and

https://www.youtube.com/watch?v=wq33c4

CNC Machine Code Language

G code and m code are the language, instructions and interpretation of cnc machine because they translate the user language into machine instructions so that it can be translated into milling, boring, turning and drilling of job. You can play with latest user friendly interface programs to operate machine but it will not help in every task, as here are always custom jobs in engineering workshop which need machine language translation in the form of cncg code. Thus importance of g code programming is vital for application in every machine workshop irrespective of model, make, capacity and axis.

CNC Programming Code List

G code and m code programing examples are best codes for CNC machine because these examples can tell machinist to control their job with set of instructions in syntax format. There are other examples too which can instruct machine to do machining operations in same manner, you can use that methods in their format but importance of G code and M code examples will remain vital. Because in the end of interface between machinist and machine g and m code are present to execute the job and perform the set of instruction on metallic / non-metallic workpiece.

Programming Methods / Code List:

Programming methods are other ways to instruct g and m code in way that it can tell machine that user custom instructions are here to follow. List of these methods are:

1. User friendly interface.

2. Commuter Aided manufacturing model.

3. Conventional Instructions.

4. Manual maneuvering of chuck and spindle.

Figure.No.2 shows modern user friendly interfaces of CNC machines without need of G and M code need, but off course it cannot translate every drawing requirement into machine language.

CNC Machine G code List

Detail knowledge of g code list, as in Table.No.1, tells that how to choose relevant codes from it and apply the same in milling, boring, turning and lathe operation so that machining operation can understand that what machinist want to have from that person.

CNC Milling G Codes

This machining operation can perform milling operation on workpiece when it is at some stationary position by making contact between job surface and cutting tool. G00 and G01 are the most popular tool that tells the user to move the tool at particular position. Another milling code G-95 and G-71 also have application for feed control and rough cycle of tool movement because tool is the main thing in this machining operation and workpiece is stationary for complete span of time, thus single code can do more work in less period of time.

CNC Milling M Codes

This operation may need to stop the operation of machining process because if tool is moving with some speed then visual inspection may need to stop for moment and do visual analysis of workpiece. Another important factor which can describe the importance of these code is that sudden accident can cause workpiece damage, which need the termination of whole process. M30 is theM codecnc which can stop the operation while keepingtheothersettingsandprogramas itis duringremainingportionof machiningtime.

Click herefor online CNC milling services from Tuofa China.

CNC Turning G Codes

This operation can remove radial material of job by moving cutting tool around the circumference of job, but off course it can rotate the tool in clockwise and anti-clockwise direction. G02 and G03 can also rotate the tool in clockwise and anti-clockwise direction, for example G02 is spindle start g code for shaft present on the chuck of machine and can have reduction in diameter after milling operation. These code can also reduce the chance of malfunction and mistake because by using this it is confirmation that you can have final job as per milling code syntax.

CNC Turning M Codes

This operation need machine related code to start, operate and stop machine as per requirement of turning operation, because stopping operation may become requirement at any industrial process. As per Table.No.2 M03, M04 and M05 are the codes for spindle rotation in clockwise and anticlockwise direction with the option of termination of process at any stage of algorithm. These codes (like M08)can also control the coolant speed during operation because if thick metallic specimen is under operation (say 100 mm carbon steel) then coolant regular speed can produce enough heat to damage the machining surface of specimen.

Difference between G code and M Codes

G and M code have many differences between them but in broader perspective it is matter of fact that G code is for numeric and positioning operations of machine while M code is for machine, accessories and tooling equipment related things. Table.No.3 describes about difference between them:

| G code | M Codes |

| Relates to geometry of workpiece | Relates to CNC machine accessories |

| Relates to product under operation | Relates to machine operations |

| Control different numeric operations of machining processes | Control PLCs of CNC machine |

| It may differ on each machine | Same is for similar origin CNC machines |

How to Read CNC Program

These programs are present from left to right side with plaintext instead of heavy text graphics and pictures with CAD / CAM model for generation of instructions to machine. G and M codes for Haas milland Fanuc control panel follow the Table.No.1 and 2 with slight modification. For example here is program:

G00 X9Y24 Now in this case probe will move toward point (9, 24) on Cartesian plane with the reference of origin already present in its program, but it will go in linear direction as description is already presentinG00.

When to Use GorM codes

CNC machine language comes from G and M codes so that engineering drawing instruction go directly to machine processor, thus you have to learn codecnc syntax for correct machining operations. And it is obvious that g code will have application in place where geometry instructions are the target to convey the instructions to the machining processor without any third medium presence. For example spindle start g code are G96 and G97 but machine instructions are also necessary to carryout this task, because they will tell that which speed and direction is need for spindle start g code.

How to Learn G Codes and M Codes

Both codes have special algorithm to learn and need special method to understand their application inCNC programming, job execution and machining operation on workpiece and metallic job. Understanding and learning of g and m codes have two aspects, first one is geometry understanding and its translation into machine code and second is arrangement of machine operations during machining operation.

G Codes:

FirstofallcodesnumberandpurposepresentinTable.No.1istheneedforunderstanding and then Table.No.3 is conjunction code for making g code detail available to machine processor. Otherwise only G02 and G03 are not enough command to tell the processor that at which speed movement should be present. Thus F syntax is also main need to tell machine that what is feed rate for turning, facing, cutting and milling.

| Command | Purpose |

| A | Tool around the x-axis |

| R | Radius of the arcs |

| X, Y, and Z | Tool Position in X,Y and Z |

| Iand J | Designate the incremental center of Arc |

| N | Line number |

| F | Feed rate |

| S | Move Spindle |

| T | ToolSelection |

| R | Radius of Arc |

| A | Tool Around Axis. |

| B | Rotation around axis |

| C | Auxiliary axis |

| D | Offset tool diameter |

| L | Loop |

| P | Delay in time |

M-Codes:

These codes are easy to learn as compare to g code reference because here you have to only tell machine that what instruction to do with its tool is. Especially in case of termination of operation M codes can help at instant speed because M00 in syntax with certain condition can stop it without prompt onscreen. Table.No. 2 describe these codes with their purpose.

How to Program G code

G code reference is start point for any translation of engineering drawing instruction into machine need syntax, for example spindle start g code can have origin but first of allG02 and G03 will tell that either to move in clockwise or anticlockwise direction. Consider the example of simple syntax:

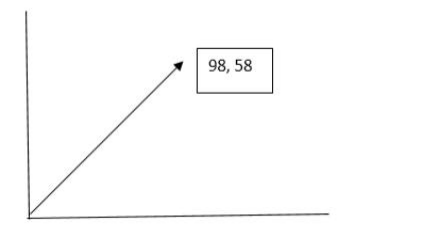

G01 X98Y58 F350

Figure.No.3. G01 Command for linear motion.

As per Figure. No.3 syntax machine will goto 98, 58 Cartesian point and feed rate will be 350 with appropriate units to perform its operation. Thus essential steps for this programming are: 1. G code algorithm. 2. Include G code Function. 3. Instruct the numeric values. 4. Insert M code for appropriate functions.

Why Choose China Tuofa to Custom CNC Machining Parts

Machining of any job need engineering drawing, qualified engineer and machinist, Calibration of CNC machine and necessary tools for machining purpose. Now you may have these kinds of facilities in your workshop but for custom parts research and experience are another additional parameters to complete the machining task within time frame work.

Tuofa China has ISO 9001 Certification and vast experience of CNC machining with auxiliary processes of engineering industry, thus Tufoa can understand the custom need of machining job and can select the best available CNC machine to achieve surface finish, tolerance and flatness as per best engineering practice.

For more information please visit tuofa-cncmachining.com

Click herefor custom parts and get quotation of your work from ISO certified organization having vast experience in machining.

FAQs

Fanuc Alarm Codes List

These alarms indicate the malfunction, wrong syntax, workpiece dimension limitation and hardware problem during operation. Some of the alarms are:

|

Alarm number |

Description |

|

0 |

No malfunction |

|

1 |

Fan Stoppage |

|

2 |

Low voltage |

|

3 |

Reduction in DC Link voltage |

G00 and G01 G-Codes

These codes are almost essential for any program of machining because G00 instruct the processor togo for particular Cartesian point with speed and G01 tells to follow the same speed as present in last time instruction.

G90 CNC Code

This code will tell processor to define another absolute positioning instead of original origin and will allow to work with new position for all references, dimension and flatness / straightness values. It can provide custom or user need reference for machining operations so that complex dot connecting dimensions are in no use of machinist.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

How to Polish Titanium | 8 Polish Ways

How to Polish Titanium | 8 Polish Ways