A2 Tool Steel: Properties, Applications and Comparisons

Dec 08,2024

Dec 08,2024

A2 steel is famous for its high durability and rust resistance. It is a well-known material in tooling and for fasteners designed to have high wear resistance and strength. More information about the composition, properties, pros and cons of A2 stainless steel is discussed in this article. A little explanation about the sub-grades of A2 steel is also provided for your information.

What is A2 Tool Steel?

A2 is an austenitic grade steel. It has around 10.5% chromium, and 8-10.5% Nickle with small inclusions of C, Mn and Si stainless steel. It has a reflective surface with a silvery touch. The demanding features of A2 stainless steel are high corrosion resistance, durability and workability. It has most applications like, stainless steel fasteners kitchen accessories, architectural and automobile parts and for chemical containers.

Why It is Known as AISI 304?

A2 and AISI 304 are closely related. A2 is the European designation and 304 is the international alloy designation. A2 is known for stainless steel fasteners and is normally referred to as 304.

Is A2 stainless steel Magnetic?

A2 stainless steel is referred to as non-magnetic material. but it could become slightly magnetic by cold working and welding.

Is A2 the Same as 304?

No, these are closely related. A2 and 304 are different designations but both have almost similar compositions.

Which is stronger, A2 or A4 stainless steel?

A4 is stronger than A4 stainless steel. A4 has 800MPa tensile strength while A2 has 600Mpa.

Is A2 the Same as 316?

No, these are not the same. A2 has higher corrosion resistance than 316(A4) but A4 is stronger

Is A2 Tool Steel for Knives?

A2 tool steel is a great choice for making knives due to its toughness, excellent wear resistance, and ability to hold a sharp edge for a long time. It's also easy to sharpen and can withstand heavy use without chipping or cracking. These properties make it ideal for high-performance knives, especially in demanding environments.

What is A2 Stainless Steel Equivalent to?

The equivalent grades of A2 stainless steel are:

- 4301-304-00-1, the ISO15510 designation

- UNSS30400 in Unified numbering system

- A2 stainless steel in ISO3506 for fasteners

- SUS304 in JISG4303 Japanese

- 4301 as EN1088

- ISCS30408 in Chinese GB/T17616

- 03Kh18N10 as 403 in GOST

Certification and Standards

- A2 stainless steel is for other than USA, according to ISO3506.

- 18/8 and 18/10 for tableware and fasteners industries

Subgroups of Grade A2 Stainless Steel

A2 is divided into 4 subgroups. These are classified based on their mechanical properties and applications.

- A2-50: known for low stress and flexible applications. It is the most economical grade.

- A2-70: one of the commonly used grades and famous as A2-70 bolt, A2-70 nuts and A2-70 bolts. It has a balance of higher strength and cost-effectiveness.

- A2-80: has high strength with hardness. It is high durability, but it is expensive among all.

- A2 100: mostly used for scoke cap screws and famous for its corrosion resistance. But it is least common among all.

Differences in Strength and Applications

|

Features |

A2-50 |

A2-70 |

A2-80 |

|

Tensile strength |

500Mpa |

700MPa |

800Mpa |

|

Yield strength |

210Mpa |

450MPa |

600Mpa |

|

Elongation |

0.6d |

0.4d |

0.3d |

|

Cost |

low |

medium |

High |

|

Applications |

For light duty parts |

Fasteners |

Automotive parts |

Common Product Forms of A2 Stainless Steel

Sheets and Plate

A2 steel in sheet and plates used for further applications like household items and appliances

Bars and Rods

A2 steel comes in square, round and rectangular bars.

Tubes and Pipes

A2 tubes and pipes are used in tools like punches, tool holders and woodworking applications and stainless steel fasteners.

Bolts

A2-70 bolts come normally in the size range of 1/4in to 24inches.

Screws

A2-70 screws come in a variety of shapes, sizes and dimensions depending on the application.

Nuts

A2-70 nuts are found in many industries, especially in medicine and in hospitals.

Washers

A2 washers have 0.093in internal Dia, 0.25in external Dia and 0.20thickness.

Pros and Cons of A2 Stainless Steel

Advantages of A2 Stainless Steel

- A2 stainless steel has high chromium content which makes it extremely corrosion resistant alloy.

- It can survive temperatures up to 870°C and short-term exposure till 925°C.

- It has high ductility and workability

- A2 perform good in cold working operations.

- A2 can retain its strength in very cold temperatures up to -196°C.

- It has high weldability due to austenitic structure.

Limitations of A2 Stainless Steel

- A2 is recommended for marine or chloride containing environment. It is prone to pitting and stress corrosion cracking.

- A2 can have carbide precipitation in operating temperature from 425- 870°C which reduces its corrosion resistance.

A2 Stainless Steel Properties

Corrosion Resistance

A2 has high corrosion resistance in acidic, humidity and alkalis environment. It is recommended for chemical and architectural applications. But it is not a marine grade stainless steel. it is not suitable for chloride-containing environment

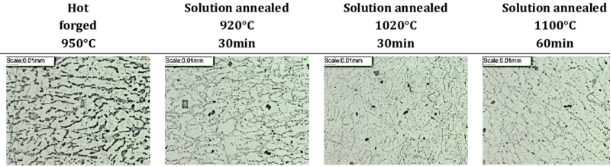

Chemical Composition and Microstructure

The chemical composition of A2 contains 18% Cr, 10%Ni, 2%Mn, 0.08%C, and inclusion of Si, P, S and N. The microstructure of A2 contains double phase of austenite and ferrite. Chromium nitride precipitates and carbide precipitates can be found on grain boundaries. Precipiates can also be present in lamellar form in the Austenite grains.

Physical Properties

Density

It has 7.75 g/cm³ density

Thermal conductivity

The thermal conduction in A2 steel is 24.9 W/m·K. It can operate at higher temperatures.

Electrical conductivity

The electrical conduction in the alloy is 2.15% IACS.

Thermal expansion

The thermal expansion is 10.2 µm/m·°C in A2 steel.

Mechanical Properties

Tensile strength

A2 is stronger and has tensile strength of 500-750Mpa

Yield strength

It has 205Mpa yield strength.

Elongation

It has high ductility and 40% elongation

Hardness

The hardness of A2 steel is 201HB and 88-HRC and 200HV.

Impact strength

A2 has good impact strength. It is used in knifemaking industries.

Fatigue strength

A2 has moderate fatigue strength.

Toughness

Toughness is good in A2 steel after air-hardening for tooling

Wear resistance

A2 steel has high wear resistance

Dimensional stability

A2 has excellent dimensional stability after heat treatment.

Welding and CNC Machining A2 Steel Parts

A2 is weldable but it can be challenging due to cracking. The welding temperature must be 250-538°C and tool steel filler material is recommended. Then, slow cooling and tempering to original tempering temperature is required.

A2 steel is one of the most commonly CNC machined material. It is easy to machine, with high wear resistance and toughness.

Heat Treatment

A2 steel can be heat treated in a conventional way. Annealing at temperatures 850°C and then air-cooling with 20°C/hour. The Brinell hardness after the treatment would be 215HB. Stress relieving carried out at 700°C and hardened at 980°C.

A2 Stainless Steel Properties Chart

|

Properties |

Values |

|

Tensile strength |

500MPa |

|

Yield strength |

205Mpa |

|

Corrosion resistance |

High |

|

Wear resistance |

High |

|

Toughness |

good |

|

Dimensional stability |

Good |

|

Hardness |

201HB/88-HRC/ 200HV |

What is A2 Stainless Steel Used for?

A2 has many applications such as:

- It is suitable for marine hardware and stainless steel fasteners for seawater or chemicals.

- Suitable for welding applications

- Suitable for coldworking operations like cutting tools and dies

- Used in food service equipment

Choose Tuofa to Custom A2 Stainless Steel Parts

When choosing a company for the custom making of stainless-steel parts, consider the following factors like material compatibility, design complexity and machining option. Tuofa offers the best services in China in all these areas. We have engineers with years of experience and skilled labor and staff with advanced machines and technology to perform any customization of steel parts.

Frequently Asked Questions (FAQ) About A2 Stainless Steel

Can A2 Stainless Steel Be Used in Marine Environments?

No, A2 is not marine grade stainless steel and has less resistance to chloride environment.

How does A2 vs A4 work in corrosive settings?

A4 is more corrosion resistant than A2 like in marine settings and industrial areas with harsh chemical environments.

Can A2 Stainless Steel Be Hardened?

Yes, it can be handed through cold working but not heat treatment.

Is A2 Suitable for High-Temperature Applications?

No, it is not suitable because it cannot be handed in heat treatments.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Aluminum 6063: Properties, Uses and Specifications

Aluminum 6063: Properties, Uses and Specifications