Aluminum 6063: Properties, Uses and Specifications

Dec 10,2024

Dec 10,2024

Aluminum is the second most used metal after iron. Al has more than 500 alloys, and Al 6063 is one of them. Since aluminium is used in every industry, it is important to discuss its alloys' properties, uses, and specifications. So, this article addresses information related to aluminium and its alloys, generally, but specifically, Al 6063.

What is Aluminum 6063?

There are more than 500 registered Al alloys, some of which are wrought and some of which are casting alloys. Al 6063 is from the 6xxx series and is a wrought Al. The main alloying elements are Mg and Si. It is commonly used for the extrusion process and has medium strength. It is weldable and heat treatable. It is regarded as architectural aluminium because of its excessive use in the architectural industry.

What Does T6 Temper Mean?

TX series provides information regarding the alloy being heat treated at a certain temperature. T6 Temper means the alloy is first heat treated at high temperatures and then the ageing process is performed to achieve precipitation hardness in the respective alloy. This process produces smooth surfaces as well.

Advantages and Disadvantages of Aluminum 6063

This section is a guide for the understanding of the advantages and disadvantages of Al 6063.

Benefits of Aluminum 6063

- Al 6063 forms a passive layer of Al2O3when it is exposed to air, that’s why it is resistant to corrosion and rust. Its high corrosion resistance makes it suitable for outdoor applications.

- It can be easily extruded into complex shapes due to ductile properties.

- The thermal conductivity of Al 6063 is superior to many metals which is why it is used in many applications in which heat dissipation is important such as cooling systems etc.

- Its thermal conductivity gradient is significantly lower which means heat does not cause stresses in the product and uniformly distributes which is why it is easy to weld. Its weldability makes it common for manufacturing industries.

- It is lightweight, recyclable and a cheaper alloy of Al.

Drawbacks and Limitations of Aluminum 6063

- It comes up with a few limitations as well which are given below:

- Its mechanical properties are not very good means its ultimate strength is 28,000 psi which is not sufficient for high-strength applications such as aerospace components.

- The strength of Al 6063 is very low, so we need to do an additional process such as artificial ageing, which adds further cost to the product.

- It can easily be prone to stress corrosion cracking which means it cannot be used in under-pressure applications.

Common Products Made from Aluminum 6063

The extrusion process is commonly performed on Al 6063 to make complex components.

Extrusions: Shapes and Sizes

Various shapes of Al 6063 are produced through the extrusion process such as tubes, bars, angles, channels, square box sections, etc. The sizes of different Al 6063 T6 are given below:

- If you have a “square box section” product, the range is from 1/3” x 3/8” x 15swg to 4” x 4” x 1/5”.

- The dimensions of a flat bar range from 3⁄8" x1⁄8" to 6” x 1”.

- If you have a tube then, the dimensions of it range from 3/8” x OD x 15swg to OD x 1/4”.

- The dimensions of a channel range from 3/8” x 3/8” x 1/17” to 10” x 3” x 3/8” x 1/2”.

- The dimensions of an Equal angle range from 3/8” x 3/8” x 1/16” to 6” x 6” x 1/2".

- The dimensions of an unequal angle range from 3/4" x 1/4" x 1/16” to 6” x 3.5” x 3/8”.

Tubes, Bars, and Angles

Tubes, bars and angles are produced from the extrusion of Al 6063.

These products are used in manufacturing industries such as:

Frames, heat exchangers etc. are formed of tubes.

Bars are used in railing, handles etc.

To make brackets, trim and architectural frames, you need angles.

Custom Profiles

Due to the feasibility of the extrusion process, it is possible to produce customized parts of Al 6063.

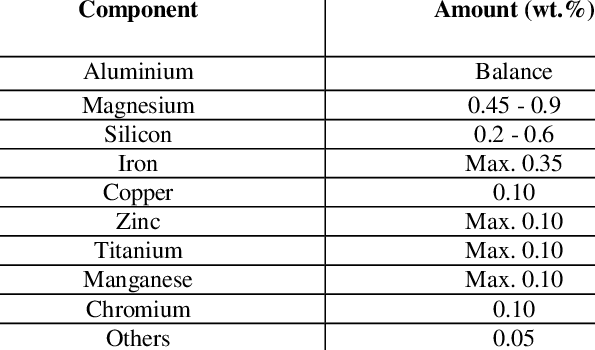

Chemical Composition of Aluminum 6063

The chemical composition of any alloy affects its mechanical and physical properties. The composition of Aluminium 6063 is shown below:

The main alloying elements are Mg and Si because Mg forms precipitates of Mg2Si which increases the strength of Al 6063 through precipitation hardening.

Physical Properties of Aluminum 6063

Physical properties are significant of importance in terms of application which are addressed here:

Density

The density of Al 6063 is 2.70 g/cm3, which is why it is considered a lightweight metal.

Thermal Conductivity

Al 6063 stands with superior thermal conductivity than many metals i.e. 201 – 218 W/[m-k]. it is the reason behind the common use in heat exchangers.

Electrical Conductivity

The electrical conductivity of Al 6063 is 3.32 X 10-6 ohm-cm.

Corrosion Resistance

This grade has good corrosion resistance due to the passive layer of Al2O3, which is why it can be used for marine and coastal applications.

Mechanical Properties of Aluminum 6063

The mechanical properties of a metal decide where it can be used for best performance, that’s why they are important to discuss.

Tensile Strength

The tensile strength of Al 6063 after heat treated and artificially aged is 241 MPa. It is the maximum load that Al 6063 can bear.

5052 vs 6063: In Aluminium alloys, strength mainly depends on the type of temper but generally 6063 Al is stronger than 5052 Al.

6005 t5 vs 6063 t5: 6005 Al is stronger (250 – 310 MPa) than 6063 Al (160 – 210 MPa).

6060 vs 6063: 6063 is stronger than 6060 Al.

Yield Strength

It means the value of load after which permanent deformation i.e. 214 MPa.

Hardness

The hardness of Al 6063 T6 is 73 Brinell Hardness.

Elongation

Elongation means how much it can be elongated before fracture. It is an important property in extrusion. Its elongation at break is 12%.

How Aluminum 6063 Performs Under Stress

It is a ductile grade of Al i.e. 12% elongation at break. It is not a stiff metal hence it performs you can say adequately under stress. Its medium strength is suitable for architectural components but not for aerospace components.

Mechanical Properties Chart of Aluminum 6063

|

Ultimate Tensile Strength (MPa) |

241 |

|

Brinell Hardness |

73 BHN |

|

Elongation at break |

12.5% of the total length, It is s1.6mm thickness |

|

Modulus of Elasticity (GPa) |

68.9 |

|

Ultimate Bearing Strength (MPa) |

434 |

|

Poison’s ratio |

0.33 |

|

Fatigue Strength (MPa) |

68.9 |

|

Shear Strength (GPa) |

28.9 |

|

Shear Strength (MPa) |

152 |

Different Tempers of Aluminum 6063

Different tempers of Al 6063 mean different tempering temperatures and holding times to produce different mechanical properties for different applications.

6063-O: Annealed Form

To produce Al 6063-O, it is annealed at 413oC. At 413oC, hold for 2 to 3 hrs and then cool at 50oF per hour from 775 to 500oF. After that heat treatment, you can achieve 89.6 MPa.

6063-T1: Strain-Hardened Form

Since it is a heat-treatable alloy, that’s why it can’t be strain-hardened. To produce Al 6063-T1 temper, it is solution heat-treated first at 520 - 540oC and then it is left at room temperature for natural ageing. After this treatment, 152 MPa strength can be achieved.

6063-T4: Solution Heat Treated

To produce Al 6063-T4 temper, Al 6063 is first solution heat-treated (520 – 540oC), quenched and then natural ageing. This temper comes up with 172 MPa strength.

6063-T5: Aged and Stretched

In this type of temper, stretching is done to relieve internal stresses. To make Al 6063-T5 temper, first extrude at (480 500oC), cool, stretch it 3-5% and then artificial ageing by heating at 175 200oC. this temper form has a tensile strength of 186 MPa.

6063-T6: Solution Heat Treated and Artificially Aged

The same procedure as the first solution is heat treatment, cooling and artificial ageing at 175 – 200oC. This temper has higher mechanical properties than the above-discussed tempers. This heat treatment results in smooth surfaces.

6063 T52 Aluminum

It is a temper of 6063 Al which is artificially aged. It has superior mechanical properties to 6063 t6 Aluminum, corrosion resistance and excellent extrudability. It is used in making window frames, curtain walls etc.

What is 6063 Aluminum Used for?

It is an architectural aluminium and is mainly used for making architectural components such as window frames, structural profiles, railings etc. Other applications include heat exchangers due to excellent thermal conductivity, boats, pipes etc. It is also used to create an aesthetic finish due to smooth surfaces.

Aluminum 6063 Welding and Fabrication

Al 6063 stands with excellent weldability and fabrication. Its easily fabricated parts include window frames, brackets etc. For its fabrication, CNC machining is a good choice because of its automation and reliability.

6063 Aluminum Weldability

This grade of Al is easily weldable due to good formability. It has high corrosion resistance and ductile which exempts the risk of cracking during welding. Any welding technique such as arc welding, gas welding etc. is applicable for welding on this grade.

CNC Machining Aluminum 6063

As you know Al 6063 has very good machinability which is why it can easily be machined on a CNC machine. You can perform operations such as tapping, drilling, milling etc. very easily. The following images are connectors fasteners and brackets of Al 6063 produced by CNC machining.

Aluminum 6063 Specifications and Standards

In this section, some of the Al 6063 specifications and standards are given:

ASTM Standards for Aluminum 6063

ASTM stands for American Society of Testing and Materials. The following are the ASTM standards of Al 6063.

| ASTM Standard | Description |

|---|---|

| ASTM B361 | Standard for aluminum castings |

| ASTM B345 | Seamless aluminum pipe standard |

| ASTM B491 | Standard for aluminum alloy pipes |

| ASTM B429 | Aluminum pressure vessel standard |

| ASTM B483 | Rolled aluminum bar standard |

| ASTM B210 | Aluminum alloy bar standard |

AMS Specifications for Aluminum 6063

AMS stands for Aerospace Material Specification. These specifications include aerospace-grade materials. For Al 6063, AMS 4156 is the relevant specification.

Other Relevant Standards

Other relevant standards of Al 6360 include:

| Standard | Description |

|---|---|

| AA 6063 | AlMg0.7Si |

| AlMgSi0.5 | Alloy composition of aluminum |

| MIL G-18014 | Military standard for aluminum alloys |

| MIL W-85 | Military standard for aluminum welding |

| SAE J-454 | Automotive engineering standard for aluminum alloys |

Summary of Aluminum 6063-T6

If we summarize the related to Al 6360, it includes it is an architectural aluminium which possesses medium strength and fine ductility i.e. 12% elongation at break. it contains Mg and Si as the main alloying elements and is heat-treatable. Artificial ageing is a process to increase the strength. It can’t be used for high-strength applications.

Recap of Key Properties

A recap of the key properties is that Al 6063 has good corrosion resistance and is lightweight. Its thermal conductivity is superior to many metals and is used mostly in heat exchangers. It has medium strength that’s why it is used in making architectural components.

Why Aluminum 6063-T6 is a Popular Choice

Al 6063 – T6 is a popular choice because it is corrosion-resistant due to the passive layer and provides medium strength. It is easy to weld and machine, that’s why it is used in manufacturing industries.

Aluminum 6005 t5 vs 6063 t5

6005 t5 provides better mechanical properties than 6063 t5. 6063 gives a tensile strength of 160-250 MPa while 6005 t5 has a 250-310 MPa tensile strength. Both are heat treatable but 6005 t5 is used in high strength applications.

Aluminum 5052 vs 6063

Al 5052 is of greater strength than Al 6063. Al 5052 is from the 5xxx series, it can’t be heat-treated. Its strength is increased via the strain-hardening process.

Aluminum 6060 vs 6063

6063 is stronger (160-250 MPa) than 6060 (140-160 MPa). Both are heat-treatable and can be extruded to produce complex shapes.

Frequently Asked Questions (FAQs) About Aluminum 6063

What is the difference between Aluminum 6063-T6 and 6061-T6?

T6 means the strengthening mechanism for both alloys is artificial ageing. The yield strength of Al 6061-T6 is higher than 6063-T6.

Can Aluminum 6063-T6 be used for outdoor applications?

Yes, it is the best choice because of good corrosion resistance and good strength. It is a cost-effective choice because of the lower cost of machining.

What are the best welding methods for Aluminum 6063?

Al 6063 is easy to weld. TIG and MIG welding techniques are considered as the best welding methods for Al 6064.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

ABS Plastic Melting Point: Properties & Applications Guide

ABS Plastic Melting Point: Properties & Applications Guide