What is the Melting Point of Titanium?

By understanding them, you will see why people prefer titanium. Industries such as aerospace, medical, and manufacturing use it. Its melting point impacts its use in many industries. It has a high melting point. This, combined with its other unique proper

May 31,2024

May 31,2024

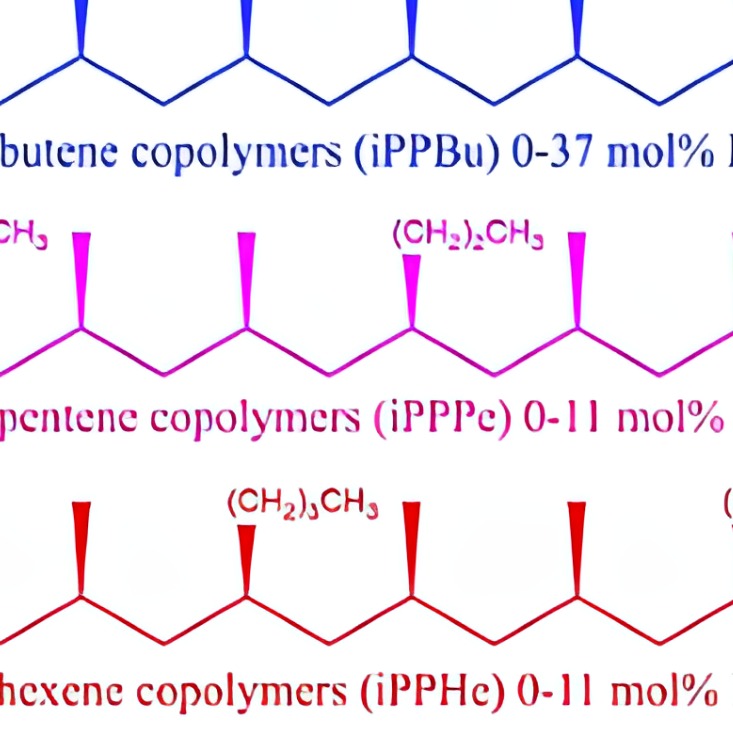

Types, Properties, and Applications of PP Copolymer: A Comprehensive Guide

The carbon polymer chain having hexane, ethylene, and butene substitutional groups is called polypropylene which is a thermoplastic polymer. Polypropylene copolymer is an industrial plastic used in a wide range of applications. Commodity plastics copolyme

May 29,2024

May 29,2024

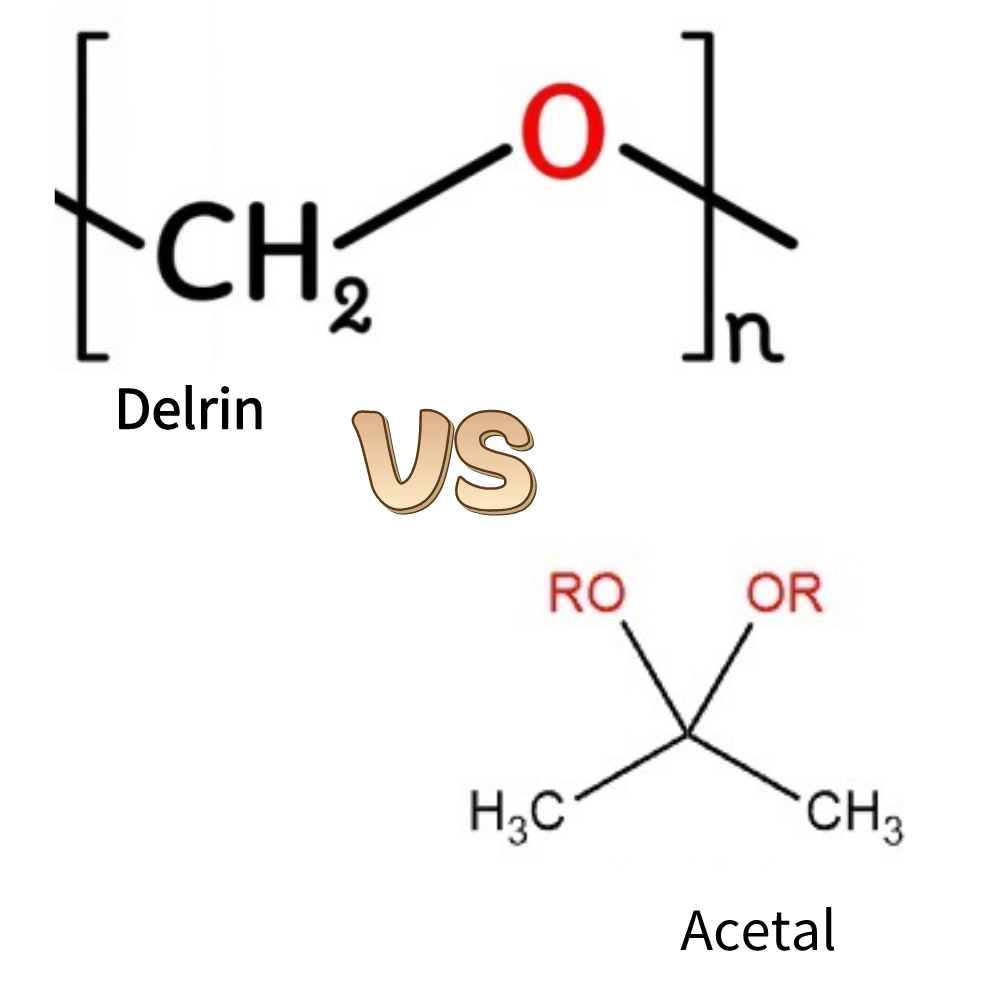

Acetal vs Delrin: A Comprehensive Comparison for Manufacturing and Mechanical Design

Polyoxymethylene, also named Acetal copolymer, is a thermoplastic which has semi-crystalline nature. Acetal copolymer has excellent dimensional stability, durability, and high friction. Acetal homopolymer known as Delrin has exceptional stiffness, strengt

May 29,2024

May 29,2024

Stainless Steel Melting Point: An Essential Guide for Mechanical Engineers

Stainless steel has a range of composition depending on the demands. Based on microstructures, these are like austenitic grades (316, 304), ferritic grades (430, 434) and martensitic grades (410, 420). Similarly, they can be categorized as alloying elemen

May 29,2024

May 29,2024

Understanding Metal Melting Points: A Comprehensive Guide for Manufacturing Professionals

This article will highlight the importance of metal melting points in manufacturing processes. The lowest melting point in metals is mercury which is -38 degrees Celsius. The highest melting point is of tungsten which is 3422 degrees Celsius. This shows t

May 13,2024

May 13,2024

15 Things You Didn't Know About Brass Alloy

Brass, a distinct and versatile metal alloy primarily composed of copper and zinc, has played a pivotal role in manufacturing and technological advancements across numerous industries. Its unique properties, including superb malleability, corrosion resist

May 10,2024

May 10,2024

What is Brass Made of: Composition, Properties, and Applications

Brass is an essential alloy in manufacturing, known for its resilience and versatility. At Tuofa, we specialize in utilizing brass in our CNC machining processes, ensuring that we meet the diverse needs of our clients with precision-engineered brass compo

May 08,2024

May 08,2024

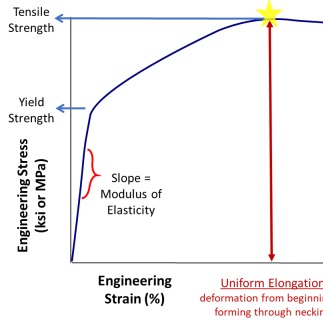

What is Tensile Testing: Methods, Types, and Data Analysis

Tensile testing is one of the types of mechanical testing. It is the simplest and most frequently used testing method to determine material’s properties. It is carried out by determining the load that is needed to deform the material to its failure

Mar 29,2024

Mar 29,2024

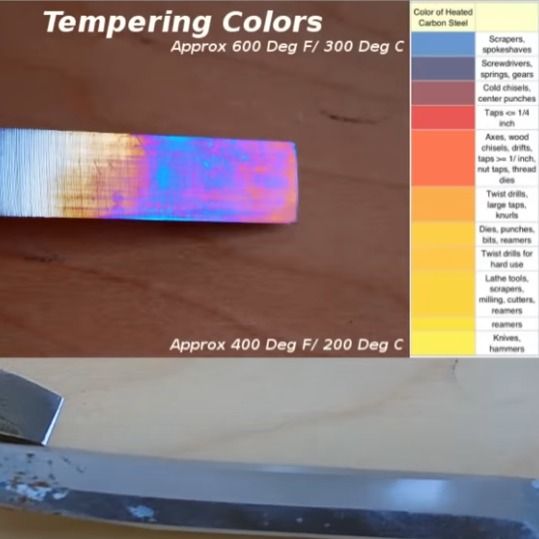

What is Tempered Steel and Why is Tempered Metal Important?

In the world of metallurgy, tempered steel stands as a keystone on the basis of its importance in various industrial usage and applications especially when this material goes through heat treatment process via different temperature variations. The process

Mar 15,2024

Mar 15,2024

The Role of Temperature in Steel Hardening: A Comprehensive Guide

As industry professionals in the manufacturing and mechanical sectors, we understand the importance of temperature for hardened steel. In this guide, we'll delve into the role of temperature in steel hardening, providing insights to understand this cr

Mar 14,2024

Mar 14,2024

12 Benefits of Steel Hardening: Impact on You

At Tuofa, we specialize in advanced CNC machining and understand the critical importance of material treatments like steel hardening. This process not only improves the longevity and performance of steel components but also significantly impacts their eff

Mar 14,2024

Mar 14,2024

The Drawbacks of Steel Hardening: Potential Challenges and Solutions

At Tuofa, we understand the critical role of steel hardening in manufacturing and mechanical design. This process, integral to enhancing the durability and wear resistance of steel components, is not without its challenges. Here, we'll delve into the

Mar 14,2024

Mar 14,2024

Case Hardening vs Through Hardening: Understanding the Differences in Steel Treatment

China Tuofa's expert guide on steel hardening – a critical process in both manufacturing and mechanical design. Our expertise lies in the detailed understanding of these processes, crucial for enhancing the durability and functionality of a wide

Mar 13,2024

Mar 13,2024

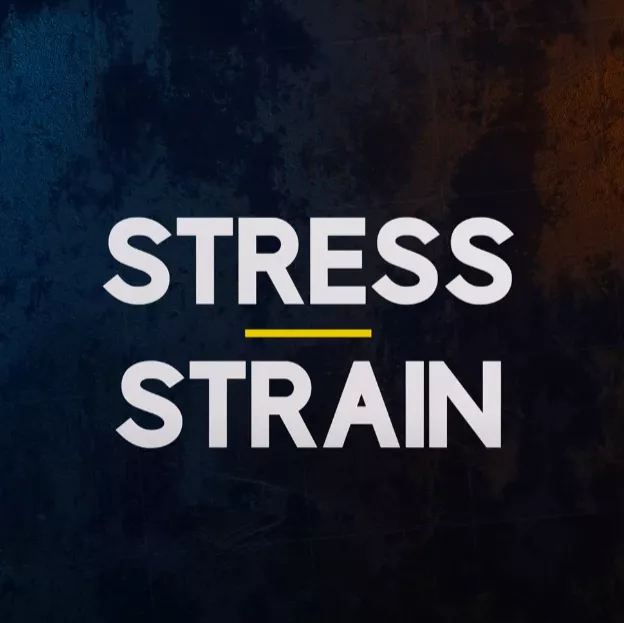

Stress and Strain in Focus: Key Differences and Engineering

Stress and strain are influential phenomena in engineering and technology. They give insight about the mechanical properties of a material. Stress develops when a pressure is applied on an object. This enables the deformation which is called strain. So ba

Mar 13,2024

Mar 13,2024

7 Techniques for Steel Hardening | How to Harden Steel

The hardening process is done on steel to increase the strength and hardness of steel parts. Steel hardening techniques are performed on specific parameters to improve the mechanical properties, especially the hardness of the steel components. In this art

Mar 08,2024

Mar 08,2024

Ultimate Guide to Black Anodizing: Process, Benefits, and Applications

If you are not familiar with black anodizing, then we can explain it for you in simple words. It is a practice of anodizing aluminum (Al). And then dye it black color with appropriate quality dye. This method is not same as black oxide because Al parts ca

Feb 24,2024

Feb 24,2024

Alodine vs Anodize, A Comprehensive Comparison

Before starting the comparison between Alodine and anodize, you must know what actually are these? Well, these are two types of finishing for Aluminum. Alodine is basically a trademark name for a certain chemical. This is also known as chromate conversion

Feb 15,2024

Feb 15,2024

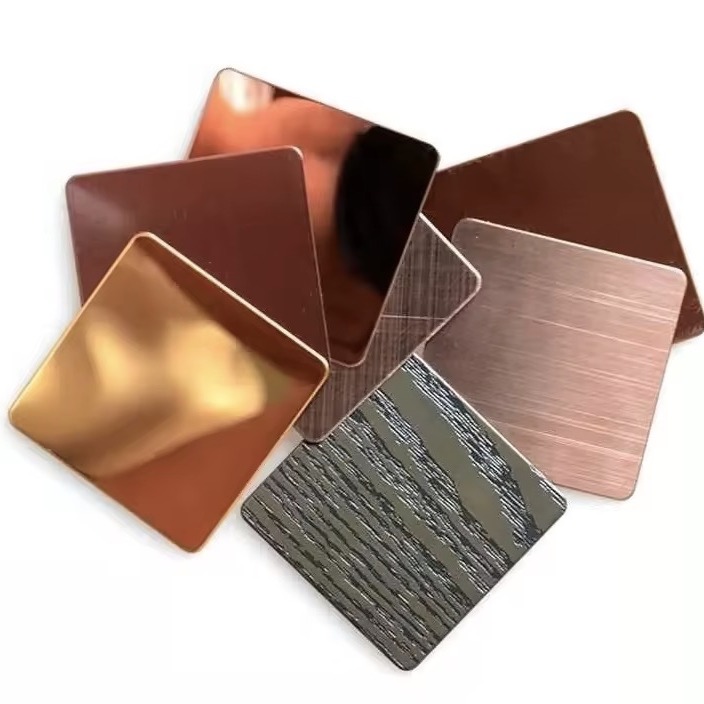

Enhancing Surfaces with PVD Coating: A Modern Solution

Specialized coatings are normally an essential part in industrial procedures for surface enhancement of high-performance products. They are applied for surface, tools, and equipment protection to enhance durability and performance. PVD metal finish is one

Feb 13,2024

Feb 13,2024

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address