What’s EN AW-6082 T6 Aluminum Alloy: Key Properties and Applications

Apr 18,2025

Apr 18,2025

EN AW-6082 T6 is a European standard high-strength aluminum alloy widely used in industrial and structural fields. It's a versatile material known for its strong mechanical properties, making it suitable for critical applications in aerospace, automotive, and construction industries. This article explores the key properties, applications, and machining considerations for EN AW-6082 T6.

What Is EN AW-6082 T6?

Before diving into the specific applications of EN AW-6082 T6, it's important to understand the fundamentals of this alloy and what sets it apart from other aluminum alloys.

What Does "EN AW" Mean?

- EN = European Norm

Compliance with EU-wide material standards set by the European Committee for Standardization (CEN). Equivalent to ISO standards but specific to Europe. - AW = Aluminum Wrought

Wrought refers to alloys shaped by mechanical processes (rolling, extrusion, forging) rather than casting. It differentiates from cast aluminum alloys (designated as EN AC, e.g., EN AC-43100).

Overview of EN AW-6082 T6

EN AW-6082 T6 is a high-strength, heat-treatable aluminum alloy. The T6 temper indicates that the material has been solution heat-treated and artificially aged. This makes the alloy suitable for high-stress applications where both strength and durability are required.

Chemical Composition of 6082 T6

Below is its detailed chemical composition per EN 573-3 standards, along with the role of each element:

Elemental Composition (Weight %)

| Element | Minimum | Maximum | Key Role |

|---|---|---|---|

| Aluminum (Al) | Balance | Balance | Base metal providing lightweight structure. |

| Silicon (Si) | 0.7% | 1.3% | Forms Mg₂Si precipitates for age hardening. |

| Magnesium (Mg) | 0.6% | 1.2% | Combines with Si to strengthen matrix (Mg₂Si). |

| Iron (Fe) | - | 0.5% | Impurity; reduces ductility if excessive. |

| Manganese (Mn) | 0.4% | 1.0% | Enhances strength and recrystallization resistance. |

| Chromium (Cr) | - | 0.25% | Improves corrosion resistance and grain refinement. |

| Zinc (Zn) | - | 0.2% | Impurity; lowers corrosion resistance if >0.2%. |

| Titanium (Ti) | - | 0.1% | Grain refiner during casting. |

| Others | - | ≤0.15% | Total impurities (Cu, Ni, etc.). |

Mechanical Properties of EN AW-6082 T6

The mechanical properties of EN AW-6082 T6 make it ideal for use in industries where high performance is essential. Let's take a closer look at its key mechanical characteristics that influence its suitability for various applications.

Tensile Strength and Yield Strength

The tensile and yield strengths are important indicators of its ability to withstand stress. With a tensile strength of around 310 MPa to 350 MPa and a yield strength of about 275 MPa, this alloy offers the strength required for structural components subjected to high loads.

Hardness and Fatigue Resistance

In addition to strength, EN AW-6082 T6 alloy's hardness and fatigue resistance are critical factors in ensuring its long-term durability. These properties make it particularly valuable in applications that involve repetitive stress or vibration.

Applications of EN AW-6082 T6

Now that we have covered the alloy's properties, it's important to examine the industries where EN AW-6082 T6 is commonly used. It is commonly used in European industries. Its excellent strength and resistance to corrosion make it a top choice for many high-performance applications.

Aerospace

In the aerospace industry, the need for lightweight yet strong materials is crucial. EN AW-6082 T6 is frequently used for structural components like wing ribs, fuselage frames, and other aircraft parts that must endure extreme conditions while minimizing weight.

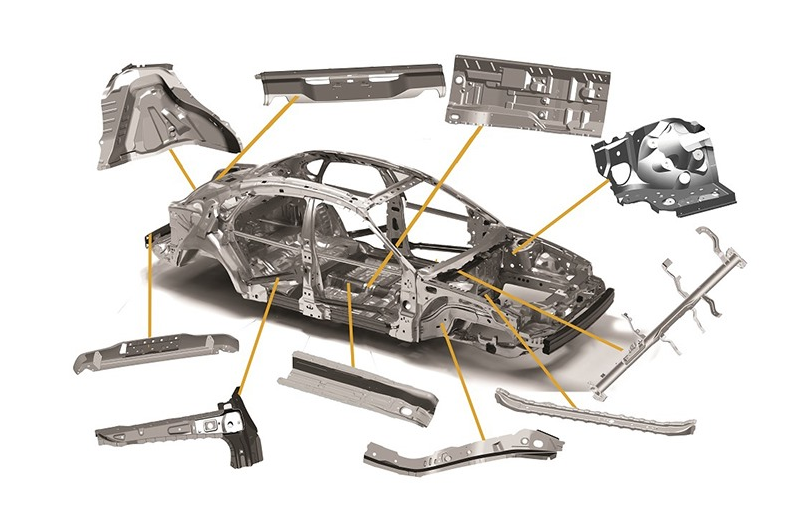

Automotive and Construction

EN AW-6082 T6 also finds applications in the automotive and construction industries. Its strength-to-weight ratio makes it ideal for parts like chassis components, suspension systems, and structural elements in buildings and infrastructure projects.

EN AW-6082 T6 vs Other Aluminum Alloys

When choosing materials for specific applications, it's important to compare EN AW-6082 T6 to other popular aluminum alloys. Below, we compare this alloy with two of the most common alternatives: 6061 T6 and 7075 T6.

6082 T6 vs 6061 T6

Both 6082 T6 and 6061 T6 are members of the 6000 series, but 6082 T6 offers superior strength and fatigue resistance. 6061 T6, while easier to weld, is better suited for applications where weldability is more critical than strength.

6082 T6 vs 7075 T6

While 7075 T6 has higher strength, it is more difficult to machine and weld. EN AW-6082 T6 provides a good balance of strength, machinability, and corrosion resistance, making it more suitable for certain applications where precision and ease of machining are essential.

How to Machine EN AW-6082 T6

Compared to other harder metals, EN AW-6082 T6 offers excellent machinability, making it perfect for structural and precision components. When it comes to machining this kind of alloy, there are many methods, today we will discuss:

CNC Machining EN AW-6082 T6

CNC machining is the preferred method for machining EN AW-6082 T6. It is a precision subtractive manufacturing method, enabling engineers to achieve tight tolerances and smooth surface finishes through optimized toolpaths and adaptive techniques. This precision ensures reliability for critical components in aerospace, medical devices, and optics.

Drilling and Cutting

Drilling and cutting 6082 requires specific techniques to avoid edge deformation and ensure clean cuts. Carbide drills and cutters are typically used to achieve optimal results while minimizing defects.

CNC Machining EN AW-6082: Steps

- Tool Selection: Carbide end mills (uncoated/TiAlN), cobalt drills.

| Operation | Speed (SFM/m/min) | Feed (IPR/mm/rev) | Depth of Cut (mm) |

|---|---|---|---|

| Milling | 600–1200 SFM (180–365 m/min) | 0.003–0.008 in/tooth (0.08–0.2 mm/tooth) | ≤5 mm (roughing), ≤1 mm (finishing) |

| Turning | 800–1500 SFM (245–460 m/min) | 0.004–0.012 IPR (0.1–0.3 mm/rev) | 1–4 mm (roughing), 0.2–0.5 mm (finishing) |

| Drilling (10 mm) | 200–300 SFM (60–90 m/min) | 0.005–0.008 in/rev (0.12–0.2 mm/rev) | - |

| Tapping (M6) | 30–50 RPM | - | - |

- Coolant: Water-soluble fluid for heavy cuts; dry machining for finishing.

- Chip Control: High-pressure coolant or compressed air.

- Surface Finish: Reduce feed rate ≤0.12 mm/tooth; polished tools.

- Post-Processing: Deburr with nylon brushes; anodize for corrosion resistance.

Heat Treatment and T6 Tempering

The T6 tempering process significantly enhances the properties. Understanding the heat treatment process is key to achieving the desired material performance.

What Is T6 Heat Treatment?

T6 heat treatment involves heating the material to a high temperature, followed by rapid cooling and artificial aging. This process maximizes the alloy's strength and hardness, making it more suitable for high-performance applications.

Aging Process and Its Effects

The aging process increases the strength of 6082 T6 alloy by precipitating solute particles in the material. This helps improve its overall mechanical properties, including tensile strength and hardness.

Welding and Joining

Welding might present some challenges, but with the right techniques, these can be overcome. Below, we explore the methods used to join this alloy effectively.

Welding Techniques

TIG and MIG welding are commonly used methods for welding 6082 T6. Both techniques offer strong welds, but proper filler material selection is crucial to ensure good weld quality.

Custom EN AW-6082 T6 Solutions for Manufacturing

Many manufacturers require custom solutions when using this alloy. Below, we explore how this alloy can be tailored to meet specific needs in the manufacturing process.

Custom Fabrication

Custom fabrication of 6082 T6 involves precision cutting, machining, and assembly to create parts suited for unique applications. This process ensures that parts meet specific design requirements.

CNC Customization

CNC machining allows manufacturers to achieve high precision and create complex parts from 6082 T6 alloy. The process is ideal for producing custom components that require tight tolerances. And TUOFA CNC precision machining shop might be the better choice for the ones looking for quality services.

TUOFA CNC Precision Machining Manufacturer

With nearly two decades of expertise, TUOFA delivers precision CNC machining for metals and engineered plastics, specializing in hard-to-machine metals like titanium alloys and nickel-based superalloys. Trusted by European OEMs for end-to-end solutions from prototyping to mass production.

Why Partner with TUOFA?

- Material Mastery: ISO-certified processes for aerospace-grade alloys.

- Design-to-Reality: DFM analysis, rapid prototyping, and tight tolerances (±0.01mm).

- European Compliance: REACH/RoHS-aligned.

Conclusion

EN AW-6082 T6 offers excellent strength, machinability, and corrosion resistance, making it ideal for demanding applications in aerospace, automotive, and construction industries.

FAQs

What are the main advantages of EN AW-6082 T6 over 6061 T6?

EN AW-6082 T6 offers higher strength and better fatigue resistance, making it ideal for high-stress applications compared to 6061 T6.

How does the heat treatment process affect EN AW-6082 T6?

T6 heat treatment enhances the alloy's strength, hardness, and overall mechanical properties, making it suitable for demanding applications.

What is the cost of EN AW-6082 T6 compared to other aluminum alloys?

EN AW-6082 T6 is more affordable than alloys like 7075 T6.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Monel vs Inconel: Which Nickel Alloy Better?

Monel vs Inconel: Which Nickel Alloy Better?