Monel vs Inconel: Which Nickel Alloy Better?

Apr 16,2025

Apr 16,2025

Monel and Inconel both have nickle as a primary element and other elements chromium, copper, iron, carbon, cobalt, molybdenum and many. But the main difference in composition is monel has copper 30-40% of its weight and inconel has chromium as main secondary element. Inconel also know as supperalloys because of high corrosion resistance and high temperature resistance. Monel has high seawater and salt resistance. Both are exceptional and have different features, uses and limitations. This article will explore all these important aspects of Monel and Inconel in detail

What Are Monel and Inconel? Are They All Nickel Alloy?

Yes, both are nickle alloys but are different in composition and applications.

What Is Monel Alloy?

Monel is nickle-copper alloy and has Ni 66%, Cu 31.5% with Fe, Mn, C and Si in small amount. It is best for corrosion resistance and seawater resistance applications. Monel 400 is the most common grade used in steam and seawater applications.

What Is Inconel Alloy?

Inconel is Ni-chromium alloy and has 50-72% Ni and 14-21% Cr with Fe and Mo in small amount. It is best for high temperature, oxidation and corrosion resistance applications. Inconel 600 and Inconel 625/718 are famous grades for aerospace and marine application

What Is Stronger Than Inconel?

Inconel itself is stronger and famous for its high corrosion and oxidation resistance and strength but titanium alloys and martensite stainless steels have higher strength at low temperatures

Is Monel or Inconel Superalloy?

Inconel is a supperalloy and Monel is Ni-Cu alloy. However, some Monel alloys are famous for is strength and corrosion resistance like Monel 400

What Are Monel and Inconel Made Of?

Monel is made of nickle(66%) and copper(31.5%) primarily while Inconel is a nickle-chromium alloy with chromium as second main element

Monel Chemical Composition

Monel has nickle and copper with some amount of iron, manganese, silicon, aluminum and titanium in some variants.

Inconel Chemical Composition

Inconel has austenitic nickle and chromium with small amount of iron and molybdenum. It is a supperalloy and is extraordinary alloy with remarkable applications

What Are the Core Composition Differences?

The major difference ins copper and chromium which impart many applications differences in both the alloys. Cu increases marine environment resistance and temperature resistance while Cr increases corrosion resistance at higher temperatures.

|

Elements |

Monel |

Inconel |

|

Ni |

63% |

72%max |

|

Cr |

- |

14% |

|

Cu |

28-34% |

0.5 |

|

Fe |

2.5% |

6-10% |

|

Mo |

- |

8-10% |

|

Mn |

2% |

1% |

|

Ti |

0.8% |

0.2-1.75% |

|

Al |

0.05-3.15% |

0.8-0.5% |

|

Si |

0.5% |

0.5% |

|

C |

- |

0.15% |

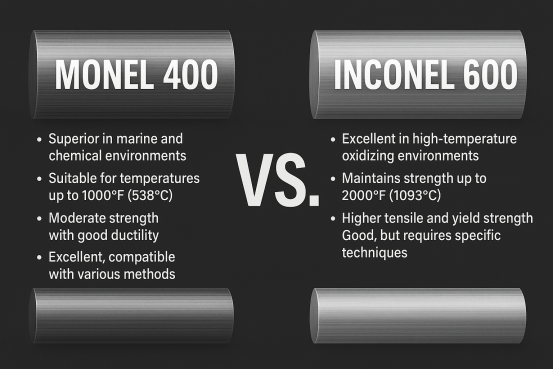

Monel vs Inconel: Main Differences

Both have different composition which changes their properties and applications.

Which Is More Corrosion-Resistant?

Both have high corrosion resistance for different environments. Inconel have high resistance to marine, saltwater, hydroflouric and sulfuric acid. While monel has high corrosion resistance to elevated temperature

Is Monel Better Than InconelIn Strength?

The strength of monel is lower than Inconel and hardness is also lower. But in annealed condition both have lower hardness than hot and cold worked conditions.

Which Is Cheaper?

The cost of inconel is very high than monel. This is due to a higher nickle content in Inconel. Nickle itself is an expensive element. It makes both alloys expensive than other common stainless steels. But between these alloys, monel is cost-effective and cheap.

Which Is Higher Temperature Limit?

Monel alloys can perform in sub-zero temperatures and can work in elevated temperatures as beyond as 1000°F. Inconel also have good performance at lower temperatures but it works better in elevated temperature up to 2200°F

What Are Their Most Common Applications?

Both are nickle-based alloys but have unique properties and applications. Inconel is mostly utilized in high-temperature resistance applications like automotive, aerospace, in high-stress parts and engine parts in power production industries.

While, Monel has high corrosion resistance suitable for marine, oil and gas companies, and chemical industries for piping system, shafts and valves.

How Do Monel and Inconel Compare to Other Alloys?

Monel and inconel are nickle-based alloys while other common alloys like stainless steel or carbon steel mostly are iron-based alloys. Monel and Inconel offer high temperature and corrosion resistance much higher than these steel. The properties of steel can be enhanced by adding small of alloying elements like Cr, Ni, Mo to increases corrosion resistance and strength. But overall monel and inconel are better in properties than stainless steels.

How Does Monel Compare To Stainless Steel?

Both offers high corrosion resistance but Monel is also suitable for harsh environment and saltwater. While stainless steel is more cost-effective and widely available than monel

Can Monel And Stainless Steel Be Used Together?

Yes, both alloys can be used together. But it must be be kept in mind that it may lead to galvanic corrosion if proper insulation and isolation is not done. Monel is a more noble alloy than stainless steel and will act as cathode in galvanic coupling. This lead to making stainless steel anodic which can corrode easily and rapidly.

How Does Inconel Compare to Titanium?

Inconel and titanium excel in different areas. Inconel is best for extreme elevated temperature and stress resistance applications like chemical processing and aircraft engines. Titanium, has high strength-to-weight ratio and easy processing which is suitable for applications like medical implants, marine and aerospace applications.

ls lnconel Stronger Than Titanium?

Inconel is stronger than titanium in strength especially at higher temperatures. Titanium alloys have higher strength-to-weight ratio and has lesser strength than inconel alloy like inconel 718.

Monel Vs Inconel Vs Hastelloy:

In terms of acid resistance, Hastealloys have higher performance in harsh and oxidizing environments. Monel is suitable for acid resistance applications for hydroflouric acid and sulfuric acids in marine environment. While Inconel has resistance for oxidizing and reducing environments but not suitable for acid like as hastealloy.

When Should You Use Monel vs Inconel?

Monel must be chosen for marine applications, acidic corrosive environments, high strength and lightweight applications and for room temperature applications because Cu decreases resistance at higher temperatures.

While, Inconel is best for high-temperature applications, oxidizing environments, high-stress structural parts, and for thermal and electrical insulation

When to Choose Monel? -Monel Applications

Here is a brief detail about the application of Monel

- Marine & Offshore Engineering

Monel has high seawater and rapid corrosion resistance which is suitable for piping systems, vales and other marine hardware. Its high strength and corrosion resistance make it also suitable for propeller shafts and pumps and for subsea structures in splash zone. Its fasteners are uses in offshore drilling which is crucial for high temperatures applications.

- Oil & Gas

Monel is widely used in oil well drilling collars and as downhole tools and drilling equipment due to surviving high pressures and temperatures. It offers high stress corrosion cracking ideal for pipelines in oil and gas industries and heat and corrosive chemicals in refinery components.

- Chemical Processing

Monel can work perfectly in harsh chemicals and high temperatures in heat exchangers and reactors in chemical industries. It offer resistance to wide range of acids and alkalies perfect for vessels and piping in chemical plants. Furthermore, it is also best for storing gasoline and other chemicals as storage tanks

ls Monel Hard To Machine?

Yes, machining of monel is harder than other common stainless steels. It has maintainability rating of 45%. It is because of high work hardening rate and requires specialized tools and training.

- Monel Turning Methods

Monel turning process is shaping the alloy by using lathe. It requires careful consideration due to high work hardening rate and difficult machining. Carbide tools with diamond coating and others are used and speed is kept minimal due to thermochemical instability. Water-based coolant and wet grinding with Al2O3 wheels or belts are used to manage heat and for better surface quality.

- Monel Milling Methods:

Milling monel requires careful consideration especially in Monel 400/K500 due to high hardness and low heat conduction. Traditional milling methods on Monel can have various challenges like high tool wear and poor surface quality. Therefore, non-traditional methods are used like electrical discharge machining (EDM), laser beam machining or wire EDM. These are suitable for hard-to-machine alloys with low cutting speed and feed rate, and with coolant and lubricant.

When to Choose Inconel? -Inconel Applications

Here is a brief detail about the application of Inconel

- Aerospace & Jet Engines

Inconel performs well in high temperature environments and ideal for jet engine parts and thermal processing equipment. It offers high fatigue strength and weldability ideal for demanding mechanical applications in aerospace.

- Extreme Environments

It is used in extreme environments such as in nuclear reactors for core parts, and engine parts of aircraft like fuel lines and ducting system due to high corrosion and high-temperature resistance.

- High-Stress Industrial

Its resistance to pitting, oxidation and corrosion is best for harsh environments and high-stress environments like marine, and for piping systems, downhole tools and wellhead equipment in oil and gas industries.

Which Is Harder To Machine: Monel Or Inconel?

Inconel is typically harder to machine due to high work hardening rate, strength and generating high heat during machining. While Monel machining is challenging for some grades like Monel 400/K500 which requires specialized tools and techniques to get better surface finish.

How to Weld Monel and Inconel?

A step-to-step guidelines to weld monel and inconel are explained below

How to Weld Monel Alloy

The key steps to weld the Monel alloy are as:

- Throughly cleand the welding surface to remove an dirt and greases by degreasing or steel wire brush.

- Select appropriate joint desing based on applications and preapre the adges of joints if requires

- Select sutibale welding process like GTAW or TIG for Monel welding for precise control on clean weld. GMAW or FCAW can also be used for Monel welding

- Select suitbale filler metal like ERNiCu-7, and welding paramets like current, voltage, and wire feed rate (for GMAW or FCAW) for welding Monel.

- Use iner shileding gas like argon or mixture of argon and helium to prevent contamination

- Preheat if requires and start welding procedure by maintaining short arc length, moving steadily and use backing gas if necessary.

- Use post welding procedure to remove slag and oxide and properly inspect visualy to check defects and flaws like crack or incomplete fusion.

ls Monel Hard To Weld?

No, monel is relatively easy to weld and can be welded by traditional processes. But its not that simple as for metal or stainless steels still easier than Inconel

How to Weld Inconel Alloy

The key steps to weld the Inconel alloy are as:

- Prepare the surface by cleaning, edge preparing and preheating if required.

- TIG welding process is used for inconel with a filler material such as Inconel 625/718 that matches with base metal.

- Use shielding gas like pure argon or argon-helium mix for weld protection from oxidation.

- Select appropriate welding parameters like amperage, voltage, and travel speed according to the material thickness and welding process.

- Start the process with short tack weld and then proceed with the weld in small, controlled passes.

- Use post welding process like cooling the weld, inspection to detect flaws and cracks and post weld heat treatment torelieve stresses and improve weld toughness.

What Are the Disadvantages of Monel and Inconel?

Both are exceptional alloys, still have some limitations in inconel and monel applications.

Monel's Limitations

The limitations of Monel are as:

- Corrosion Resistance Weaknesses

Monel has good corrosion resistance but it is not resistant to all forms of corrosion such as galvanic and pitting corrosion. Monel can corrode other metals when in contact with them in sever weather conditions and are prone to pitting in stagnant or slow moving saltwater.

- Machining & Fabrication Challenges

Monel is harder to machine than stainless steel and requires specialized tools and equipment, low speed and feed rate.

Inconel's Drawbacks

The drawbacks of Inconel are as:

- Corrosion & Environment Limits

It offer high corrosion resistance but it is not fully resistant to acids and mixed acidic environments and can cause pitting corrosion in their presence. Its oxidation resistance is good but not fully immune to high temperature corrosive attacks and can be severely affected especial inconel 625/718.

- Machining & Fabrication Challenges

It has high hardness and work hardening rate which makes it difficult to machine by traditional methods.

- Physical Limitations

It also ha welding issues like prone to cracking, difficult stamping and deep drawing and has heat treatment challenges like sensitivity to thermal stresses

Conclusion

Monel and inconel are nickle-based alloys and have high corrosion resistance. Monel is a nickle-copper alloy and has high marine and harsh chemical environment resistance. While inconel is a nickle-chromium alloy and has high high-temperature strength and resistance to oxidation. Inconel applications are engine components and high-stress applications.

FAQs

Is monel better than inconel for saltwater?

Yes, Monel is better than inconel for saltwater, acidic environments and marine applications due to high copper content

Can inconel rust?

No, inconel has high corrosion resistance due to high nickle and chromium content. This makes it highly corrosion resistant

ls monel rust proof?

Yes, it is rust-proof due to high corrosion resistance to marine environment and seawater

ls monel a type of stainless steel?

No, it is not stainless steel. Monel is a nickle-copper alloy while stainless steel is a iron-chromium alloy.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What’s EN AW-6082 T6 Aluminum Alloy: Key Properties and Applications

What’s EN AW-6082 T6 Aluminum Alloy: Key Properties and Applications