The Basic Requirements of Fixture Clamps for a CNC Machining Center

Dec 21,2021

Dec 21,2021

The selection of locating datum for a CNC machining center:

1.Three basic requirements for a CNC machining center to select a datum mark:

(1)The selected datum should be able to ensure the accurate positioning of workpieces be convenient and reliable for loading and unloading.

(2)Simply calculate the selected datum and the dimension of each Process parts.

(3)Ensure machining accuracy.

2.Six principles for CNC machining center to select a datum mark:

(1)Try to choose the design datum as the locating datum;

(2)When the locating datum and design datum are not unified,the positioning error should be strictly controlled to ensure the machining accuracy

(3)When the workpiece needs to be clamped and processed more than twice, the selected datum can complete the processing of all key precision parts in one clamping and positioning

(4)Make sure to complete as much processing as possible for the selected datum mark;

(5)When the batch processing, the Process part’s positioning datum should be as close as possible to the tool’s setting datum established in the workpiece’s coordinate system

(6)The datum mark should be unified when multiple clampings are required

Determination of a fixture in a CNC machining center:

1.The basic requirements of a fixture in a CNC machining center:

(1)The clamping mechanism must not affect access, and the processing part must be open;

(2)The Fixture can be installed directionally on the machine;

(3)The rigidity and stability of the fixture must be great.

2.Commonly used types of fixtures for a CNC machining center:

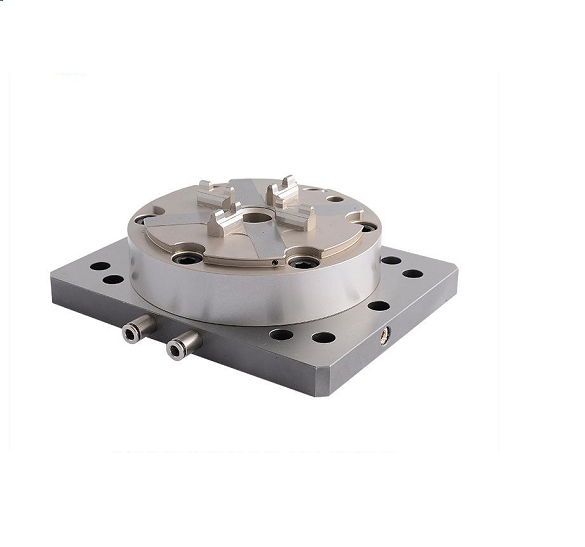

(1)General fixtures: such as vices, indexing heads, chucks, etc.;

(2)Modular fixture: The modular fixture is composed of a set of common components with standardized structure and standardized size

(3)Special fixtures: fixtures designed for certain or similar Process parts

(4)Adjustable fixtures: the combination of modular fixtures and special fixtures can not only ensure the accuracy of processing but also have more flexibility in clamping

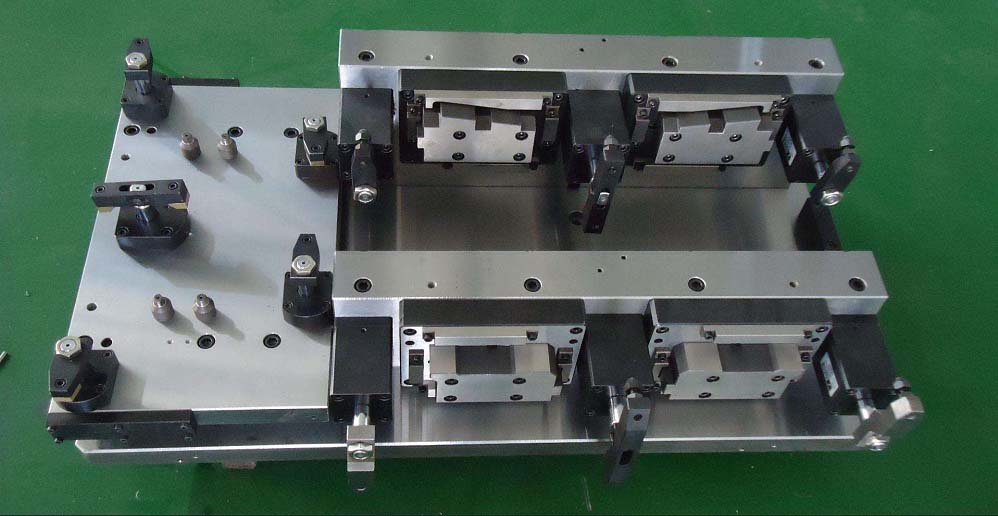

(5)Multiple-stage fixtures: Fixtures are capable of clamping multiple workpieces at the same time

(6)Group fixtures: specifically for clamping workpieces with similar shapes, similar sizes, and the same or similar positioning, clamping, and processing methods

3.The selection principle of a fixture in a CNC machining center:

(1)Under the premise of ensuring machining accuracy and production efficiency, the general fixture is preferred

(2)Simple and special fixtures can be considered for batch processing

(3)For batch processing, consider the use of multiple-stage fixtures and special fixtures such as air clamp and hydraulic clamp

(4)Group fixtures should be used when group technology is applied

Flexible solutions

Chinese machining parts manufacturers provide the best solution -ISO9001 quality control. Professional machinists in precision machining workshops customize CNC parts online

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Turning Parts Machinery and Turning Materials

Turning Parts Machinery and Turning Materials