Questions About Machining Accuracy | ISO9001 Quality Control

Jul 05,2022

Jul 05,2022

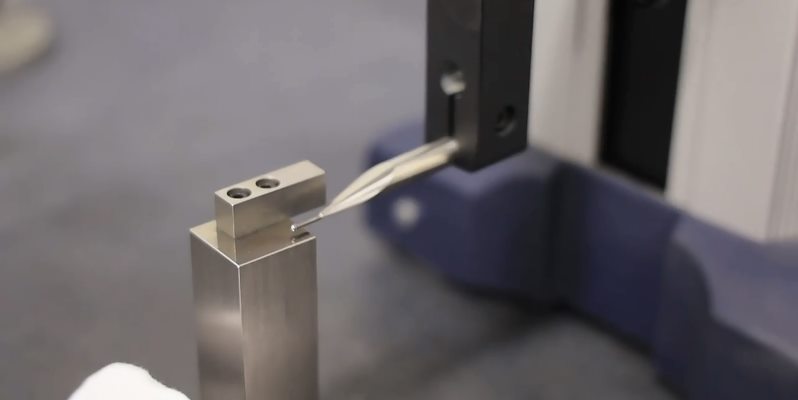

The actual parameters obtained by any machining method will not be absolutely accurate. From the function of the part, as long as the machining error is within the tolerance range required by the part drawing, it is considered that the machining accuracy is guaranteed. The workshop ISO9001 quality management system of Tuofa CNC machining parts factory, the tolerance of precision machining parts is as low as 0.01mm.

What does machining accuracy mean?

Machining accuracy refers to the degree of conformity between the actual geometric parameters (size, shape, position) and the ideal geometric parameters after machining of the part. The deviation between them is the machining error. Machining accuracy includes three aspects, dimensional accuracy, shape accuracy, and position accuracy.

What are the factors that affect machining accuracy?

The original error of the process system: the geometric error of the process system such as the processing principle error, the geometric accuracy of the machine tool, the manufacturing error of the tool and jig, the installation error of the workpiece, etc. The process system of force deformation, thermal deformation, internal stress caused by the error will affect the accuracy of the part processing. Machining principle errors such as production approximation, forming, etc., can often significantly increase productivity as long as they are limited to allowable tolerances.

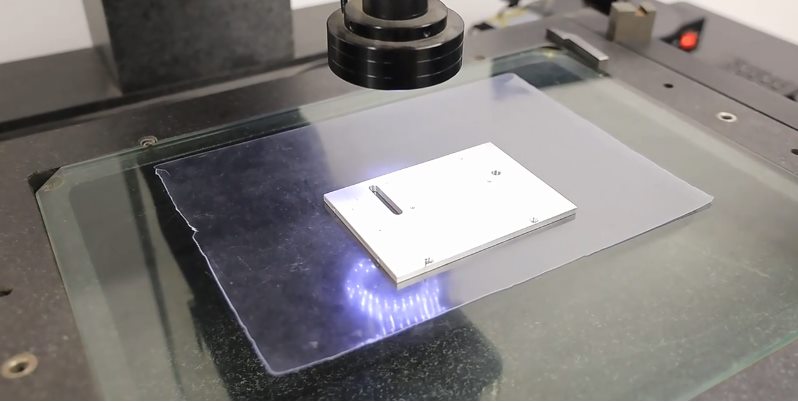

Machine geometric accuracy errors such as radial and axial runout errors during spindle rotation. The machine guide in the horizontal vertical direction of the straightness of the error, the parallelism between the guide and the guide error. The error of the drive chain of the machine. The error of tool error measurement, the error of thermal deformation of the process system. Workpiece, tool heat deformation, cutting heat, frictional heat, incidental heat, etc., so many precision machine tools are placed in the tantalizing workshop, (slow-walking machine tools, CNC machines, etc.). Deformation caused by internal stresses in the workpiece where the residual stresses in the cutting process make the workpiece deformed. Therefore, in order to reduce the original error caused by the machining accuracy, we usually think of machine tools for self-turning, self-milling, self-milling, self-cutting to try to recover the original error caused by machining errors.

Such as using the old milling machine shape of 200 * 20 * 400 aluminum alloy products parallelism, perpendicularity, flatness, within 0.03mm, such as the use of high precision lathe processing slender shaft, such as the use of the old wire-cut machine tools to process the coaxiality of the inner and outer circle within 0.02 set of parts, etc.. When we think of machining accuracy in the unmanageable when we have to think about taking the self-turn, self-milling, self-grinding, self-cutting these methods to lift.

Machining standard

The machining accuracy is measured by the tolerance level. The grade the level value, the higher the accuracy; the machining error is represented by a numerical value. The larger the numerical value, the greater the error. High machining accuracy means small machining error, and vice versa. There are 20 tolerance grades from IT01, IT0, IT1, IT2, IT3 to IT18, of which IT01 indicates the highest machining accuracy of the part, and IT18 indicates that the machining accuracy of the part is the lowest. Generally speaking, IT7 and IT8 have medium machining accuracy. level. In our Tuofa CNC machined parts factory according to the ISO 2768 standard, the metal tolerance will be maintained at +/- 0.005" (+/- 0.127mm). Plastic and composite materials will be +/- 0.010". (unless buyer requests otherwise).

Reliable CNC machining parts factory

The quality of the machine depends on the machining quality of the parts and the assembly quality of the machine. The machining quality of the parts includes the machining accuracy of the parts and the surface quality. We Tuofa CNC machining parts factory have more than 30 kinds of materials and 10 kinds of surface treatments to custom CNC parts for startups and engineers

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Surface Treatment Services | Tuofa Machining Inc

Surface Treatment Services | Tuofa Machining Inc