How Bicycle Brake Parts are Made

Jun 30,2022

Jun 30,2022

The effect of gasoline prices on bicycles

With the increase in global gasoline prices, the traditional bicycle as a means of transportation has recently been chosen by more and more people, a 1% increase in gasoline price leads on average to a 0.726% increase in total bike trip duration.Therefore, the demand for bicycle parts is also increasing. There are bicycle brakes, bicycle bells, bicycle handlebars, etc. As the Chinese saying goes, "Peace in and out", safety is always the first priority, and the safety of a bicycle is of course closely related to its brakes.

Types of bicycle brakes

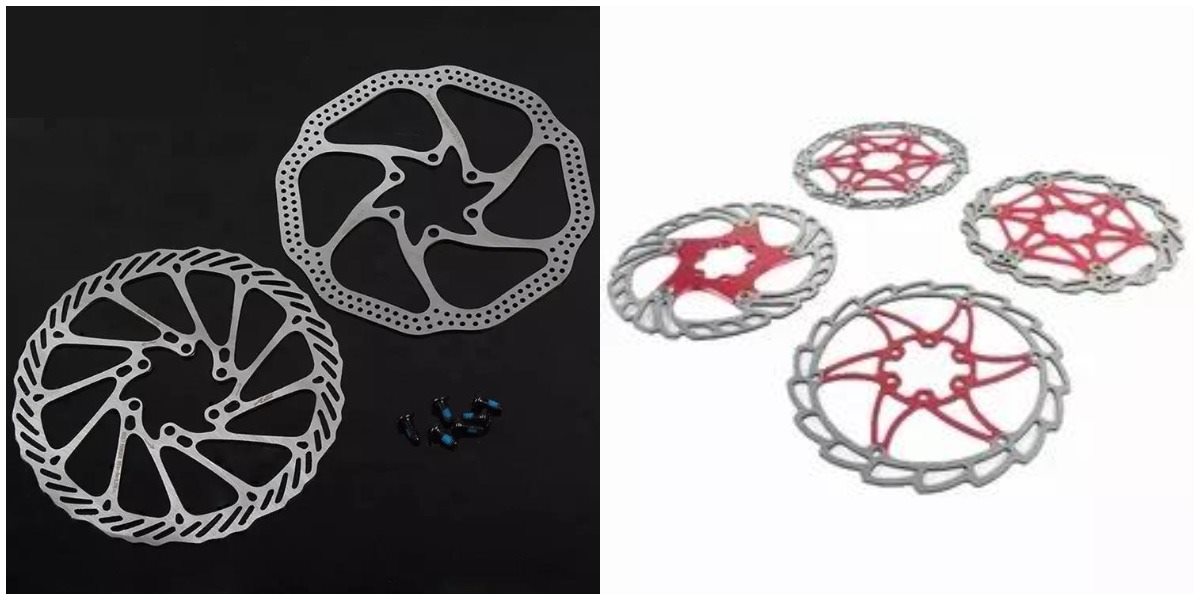

Bicycle brakes are different according to different types of brakes and different environments. There are basically three types of brakes: disc brake, V brakes, and C brakes.

What are brake parts made of?

In the production of C-brake, the clamp and the handle are two separate and synchronized production lines, which are finally assembled in the assembly line. Both clamps and handles have two production processes, die-casting and forging, except for the difference between die-casting and forging processes, and one more heat treatment process for forging.

How bicycle brake parts are made in China

I. Forging and forming

Off-forming-Forging-Fine cutting edge

- Fine aluminum profile

- Fine aluminum is cut according to the required length

- Fine aluminum is heated by heating machine and then sent to forging machine for forging and forming after heat treatment

- Then it is sent to the edge cutting machine for edge cutting

- After finishing the edges, we still need to grind the surface treatment for the small bumps.

2. Press-fit casting process

- Material preparation, material fusion, and pressing into shape

- Material proportioning according to the hardness required for each product

- The blended fine aluminum material is put into the fine aluminum furnace for fusion

- The initial semi-finished product is produced by the press casting machine.

3. Precision CNC machining bicycle brakes

The brake clamps processed by the precision CNC lathe can ensure the safety factor of the market consumers in the subsequent use.

tuofa-cncmachining.com use of precision computer lathe equipment greatly enhances production efficiency & quality stability!

4. Is it hard to assemble a bicycle?

The semi-automated machine controlled by personnel to assemble semi-finished products greatly reduces the physical wear and tear of personnel, and really improves the yield of the product, the guarantee of excellent quality is equivalent to the responsible performance of the market users! Our quality assurance is the same as being responsible to the market users!

The good and human-oriented quality working environment makes the products produced more stable and usable quality.

Clamp brake assembly

After the assembly of the clamp brake skin is completed

The importance of brakes to bicycles

Brakes are the patron saint of safety in bicycles, whether it is deceleration or emergency braking, so they are used very frequently. Therefore, the production process of brakes is also very delicate, at CNC machining factory from material proportioning to final assembly and inspection, and in view of the limited description, the above pictures are just a glimpse of the product, mainly for interested riders to understand the process behind the product.

CNC machining China factory

Shenzhen Tuofa is always on the front line to listen to the voices of employees and to create a quality working environment with heart and soul, which is called the happy factory in the industry. Online custom CNC parts Welcome to visit our factory anytime!

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Questions About Machining Accuracy | ISO9001 Quality Control

Questions About Machining Accuracy | ISO9001 Quality Control