Precision Machining 304 Stainless Steel: Tips for Optimal Results

Dec 01,2023

Dec 01,2023

In the list of stainless-steel grades, there lies a material called 304 stainless steel also known as SS304. It’s an austenitic stainless steel and belongs to the 300 series. The skill of handling 304 stainless steel is of the greatest importance in precision machining. The guide provides information regarding the techniques of machining 304 stainless steel, advantages, disadvantages, how precision machining can be done, and applications of SS304. It will also help to become an expert in machining this material. Regardless of one’s level of expertise as a machinist, this guide will benefit in advancing the knowledge in machining 304 stainless steel.

SS304 machining part

Properties of 304 Stainless Steel

Before moving on to the machining 304 stainless steel let us first look at the inherent properties of the material. SS304 is known for its ability to withstand corrosion, adaptability, and overall visual appeal. However, it can’t provide resistance to chlorides because of no molybdenum. An increase in sulfur content would increase the machinability and aid high quality precision machining. Also, a balanced set of properties in SS304 makes it a standard material in many industries.

The following table shows the values of different properties of SS304.

|

Properties |

Value |

|

Density |

8 (g/cm3) |

|

UTS |

510 (MPa) |

|

Yield Strength YS |

220 (MPa) |

|

Brinell’s hardness value |

124 |

|

Rockwell’s hardness value |

70 |

|

Vickers hardness value |

130 |

|

Knoop hardness value |

140 |

Note: Values of Brinell’s, Vicker’s, and Knoop hardness are converted from Rockwell’s value.

304 Stainless Steel Machinability Chart

Values (%) of machinability shows how much a material is machinable. For stainless steels, annealing can be done to improve the machinability, but 304L stainless steel machinability is even good without annealing. To better understand the machinability and the process of milling and turning 304 stainless steel, Following table shows the recommended values for certain operations involved:

|

Operations |

Values |

|

Machinability |

40-45 % |

|

Turning |

550-600 SFM |160-180 m/min |

|

Milling |

300-330 SFM | 90-110 m/min |

To show you how machining is being done on SS304, the following video shows turning 304 stainless steel,

Is Difficult to Machine 304 Stainless Steel on Lathe?

In recent times, CNC machining has gained a huge importance in manufacturing industries because of automation as manual methods induces a lot of defects and errors. There are certain difficulties that might occur during machining SS304 on lathe. However, they should be overcome to ensure precise machining. These difficulties include:

- Vibration of tool occurs could occur at high-speed leading to poor surface finish.

- At higher speeds, SS304 started a work-hardening phenomenon which results in higher cutting forces.

- The accumulation of heat occurs at the tool-workpiece interface which results in increased tool wear and material damage.

- Chip controlling would be difficult as they require chip breakers and proper geometry.

Do you want to know about 303 vs304 stainless steel, which material is more suitable for your project, please contact info@tuofa-cncmachining.com to give you the best answer.

304 Stainless Steel Machinability

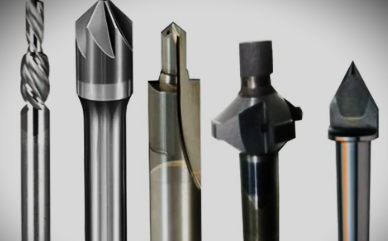

Tooling in Machining 304 Stainless Steel

Another important aspect to consider while machining any material is the right selection of the tool. The tool material itself should be compatible with the material to be machined.

- Carbide tools are often used for turning 304 stainless steels and especially 304H as they have high hardness and other required properties.

- Similarly, ceramic tools offer high speed performance and good wear resistance.

Carbide cutting tools for stainless steel

Additionally, 316 stainless steel machinability can be improved by adjusting tool geometries such as rake angle and clearance angle. Chip breakers should be used to help in keeping scrap away from the work. Furthermore, coolants and lubricants should be used to reduce heat concentration during cutting and to avoid workpiece discoloration.

8 Tips for Machining 304 Stainless Steel

To achieve optimum results after machining it is important to optimize the different parameters that are involved in the precision machining process. Following are the few techniques that can be employed to improve the machining of SS304:

1. Annealed stainless steel material

Annealing can be done to remove stresses within the material and can be prepared for better machining.

2. Use a slow cutting speed

Low cutting speeds are recommended for hard materials and for a better surface finish.

3. Use coolant or lubricant

Using coolant or lubricant during the precision machining process can help reduce heat buildup and improve tool life. It also helps to flush away chips and prevent them from re-cutting and causing tool wear.

4. Use a positive rake angle

A positive rake angle on the cutting tool helps to reduce cutting forces and improve chip evacuation. This is especially important when machining stainless steel, as it is a tough and gummy material that can cause chip packing and tool wear.

5. Take light cuts

When machining stainless steel, it is best to take light cuts to prevent excessive tool wear and heat buildup. This also helps to maintain a good surface finish and minimize the risk of work hardening.

6. Use a smaller depth of cut

Stainless steel has a tendency to work harden, especially when machined at higher speeds. To prevent this, use a smaller depth of cut to reduce the amount of material being cut at once.

7. Use a high feed rate

A high feed rate can help to improve chip evacuation and prevent chip re-cutting. This is especially important when machining stainless steel, as it is prone to chip packing and can cause tool wear.

8. Use a sharp tool

A sharp cutting tool is essential when machining stainless steel. Dull tools can cause excessive heat buildup and result

Also, SS304L can be used as it has low carbon content that helps good 304L stainless steel machinability. Do you want to know more about machining 316 stainless steel? Contact Tuofa engineers info@tuofa-cncmachining.com

Try Tuofa Now!

Send drawings to info@tuofa-cncmachining.com

Tuofa Engineer Support Team

Real human quotes are more accurate than software quotes

Surface Finish and Polishing of 304 Stainless Steel

Obtaining a good surface finish is among the final touches in the precision machining process. There are different designations for stainless steels however, the few most common and related finishes for SS304 are:

No. 1:Hot-rolled, annealed, and descaled. This finish is often used in industrial applications where heat and corrosion resistance are required.

No. 2B:Cold-rolled, annealed, and pickled. Most popular SS304 smooth and reflective finish.

No. 4:Polished finish, used for wide range of applications such as kitchen equipment, food processing, and architectural usage.

Pros and Cons of Machining 304 Stainless Steel

Advantages

- Since there is presence of sulfur in chemical composition of SS304 which aids better machinability.

- It exhibits good mechanical properties such as high tensile strength and wear resistance, making its use in high end applications.

- SS304 has better cleaning and has many different finishes and provides good oxidation resistance under exposed environments. [8]

- It has a high melting point making its use in high temperature applications.

Disadvantages

- 304 stainless steels have no resistance to corrosion in marine environment as it has no molybdenum unlike SS316.

- Its processing is relatively expensive than other stainless-steel grades.

- It is prone to work-hardening while machining which makes turning 304 stainless steel difficult.

Machining 304 Stainless Steel Uses

Due to its good corrosion resistance, high strength, good aesthetics, and high temperature enduring limits, SS304 is being used in a variety of industries. Few of its uses are as follows:

- It is being used in utensils and cookware items for making pans, bowls, pots.

- It is being used in the food industry to provide better hygiene as it shows no oxidation or degradation at elevated temperatures.

- It is being used in petrochemical industries for storage tanks to store chemicals.

- It has applications in Bio-medical as it can be used as non-reactive implants for joints.

- It can be used in the automotive industry for making rims and exhaust systems.

SS304 applications

Stainless Steel Machined Parts Manufacturers in China Tuofa

As a leading player in the industry, Tuofa (www.tuofa-cncmachining.com) stands out among stainless steel machined parts manufacturers in China. We pride ourselves on delivering precision and excellence in every component we produce.

When you choose Tuofa, you're choosing a reliable partner dedicated to meeting your exact specifications. Our commitment to quality craftsmanship and advanced machining technologies ensures that your stainless steel parts not only meet but exceed industry standards.

Ready to elevate your projects with top-notch stainless steel machined parts? Contact Tuofa today and witness the excellence that sets us apart in the world of machining. Send the drawings now to obtain a free quotation with info@tuofa-cncmachining.com

FAQs about 304 Stainless Steel

Does stainless steel 304 rust?

Stainless steel 304 has a high resistance to rust and corrosion, but it is not completely immune. Under certain conditions, such as exposure to harsh chemicals or high levels of humidity, 304 stainless steel can still corrode. However, with proper care and maintenance, it is highly resistant to rust and is often used in corrosive environments.

Is 304 stainless steel parts suitable for outdoor use?

Yes, 304 stainless steel parts is highly suitable for outdoor use. It has excellent corrosion resistance, which helps it withstand exposure to moisture, rain, and other environmental elements. This makes it a popular choice for outdoor applications such as architectural features, outdoor furniture, railing systems, and signage. However, it is important to properly clean and maintain stainless steel 304 to ensure its long-term durability and resistance to corrosion.

How thick is 10 gauge 304 stainless steel?

10 gauge stainless steel refers to a thickness of approximately 0.135 inches or 3.43 millimeters. This is a common thickness for 304 stainless steel in various applications, including fabrication, construction, and automotive industries.

How hard is 304 stainless steel?

304 stainless steel has a hardness rating of approximately 70 on the Rockwell B scale (HRB). It is considered to have a moderate level of hardness, making it suitable for a wide range of applications. However, it is important to note that the hardness of stainless steel can vary based on factors such as the heat treatment, cold working, or other alloying elements present in the material.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Milling Stainless Steel Explained: Advantages, Applications, and Processing Techniques

Milling Stainless Steel Explained: Advantages, Applications, and Processing Techniques