Riveting vs Welding: Join Sheet Metal Parts

Mar 11,2025

Mar 11,2025

You see complex structures in your daily routine, the simplest example is the bridge. Bridges contain beams and columns in their structure. We connect these pillars and columns somehow to make a bridge. Riveting and welding are two joining techniques which connect multiple parts and make a joint structure. The riveting process provides temporary joints, and welding makes permanent joints. In this article, you will read a comprehensive guide on the difference between riveting and welding.

What is Riveting in Metal Work?

Metalwork means joining metal sheets to make a joint structure. Riveting is a fastening process used to connect two sheets. Rivets are cylindrical rods with a head on one end and a flat surface on the other end. They are inserted into pre-drilled holes and then held together. The riveting process is used in many industries. The most common application is in streetlights or bridges.

You can see how many rivets are inserted into the bridge. That's how the rivets work.

Types of Riveted Joints

While riveting metal sheets together, we use different types of riveted joints. These types are briefly explained here.

Solid Rivets

These rivets are one of the oldest and are available in multiple materials such as Cu, Stainless Steel, Brass etc. You can use solid rivets in structural applications. This type of rivet provides permanent strong joints.

Blind Rivets

Blind rivets are tubular fasteners whose core centre passes through the holes. The rivets are used in installing steel sheets in the restricted areas. Its applications include the medical industry, scissors, nail cutters, dental instruments, sports and the leather industry.

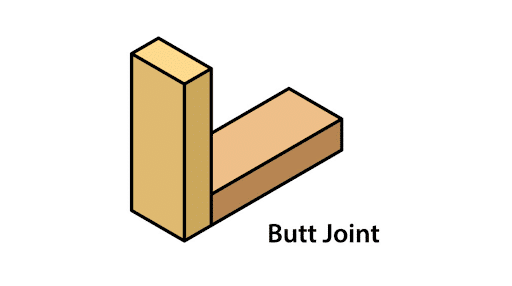

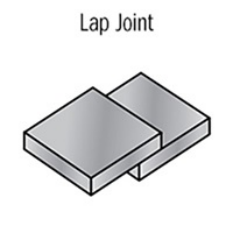

Rivet Joints

Rivet joints can be lap joints or butt joints. These joints are used for overlapping or end-to-end joints in industrial applications.

Rivet Connection Explained

A rivet connection involves inserting a rivet in a pre-drilled hole and then deforming it using a hammer or rivet gun. This process results in stronger permanent but temporary, in most cases, connections which can bear stress or vibrations easily. This riveted joint is very useful in many industrial applications.

Pros and Cons of Riveting

In this section, you will study some advantages and disadvantages of riveting.

Pros of Riveting

- Cost-effective

A rivet requires minimal material and machine, so the cost is very low. It is cost-effective but provides stronger joints.

- Ease of Use

It is very easy to use for making joints between metal sheets. You just need to insert these rivets in the pre-drilled holes and then deform them.

- Suitability of Sheet Metal

Rivets are the most suitable connectors to connect metal sheets strongly.

Cons of Riveting

- Although their riveted joints are good, their strength is still limited

- Due to the difference in material and electro potential, susceptibility to corrosion remains high

What is Welding?

We see many complex designs of pipes connected through welding. So, what is welding, and how does it do the job? Welding is a fabrication process that connects two parts through a melting process. A flame of very high temperature, i.e., 3000oC-4000oC, melts the required area of both parts and then fuses them. Welding provides very strong and permanent connections between two parts; that's why we find its applications even in the aerospace industry.

There are many welding techniques in this world, and a few of them are discussed briefly here:

- Shielded Metal Arc Welding (SMAW)

The most common technique is even used at local levels. In this technique, a consumable electrode and flux are used to make a strong joint.

- Gas Tungsten Arc Welding (GTAW)

In this technique, a non-consumable Tungsten electrode is used along with an inert gas such as helium or nitrogen. It is also known as TIG welding.

- Gas Metal Arc Welding (GMAW)

An electric arc between a workpiece and a wire electrode. This arc melts both and fuses two parts. A shielding gas protects the weld pool. It is also known as MIG welding.

- Flux-cored arc Welding (FCAW)

As the name shows, the flux is present in the core of the consumable tubular electrode. So, flux is not required separately.

Types of Welded Joints

Now, we will see some types of welded joints in this part of the article:

Butt Joint

A joint where two pieces of metal plates are connected end-to-end without overlapping. There is no special joint.

Fillet Joints

If you have perpendicular or angled metal pieces, use fillet joints. These welded joints are referred to as T-joints.

Lap Joints

Just overlap two metal sheets and weld them along the edges; it is called a lap joint.

Pros and Cons of Welding

Now, we will discuss some pros and cons of welded joints in this section.

Pros of Welding

- Stronger Joints

Since the metal sheets are fused into each other, the joint is very strong.

- Cleaner Finish

Welded joints are aesthetically pleasing because the appearance of these joints is seamless.

- Versatility

There are so many welding techniques, which is why, in welding, there is no issue of material. Welding joints apply to every material.

Cons of Welding

- Human Injury

The chances of skin burns are high because of heat.

- Skilled Labour

To make welded joints, you will need proper skilled labour.

- Higher Setup Cost

For welding, you will need many things such as gases, electrodes, PPEs, machines etc. These things make welding more expensive than riveting.

What are the Differences Between Welding and Riveting

Although welding and riveting are both joining processes, they are different in many aspects. This section presents detailed lists of differences between riveting and welding.

Materials and Metal Compatibility

In the case of riveting, the main issue is galvanic corrosion because of the difference in electro potential between metal sheets and rivets; for instance, you can see this in the streetlights as well. Welding is preferable for materials like Aluminum and steel. Riveting is compatible with those materials which are heat sensitive.

Speed and Efficiency

The efficiency of any process depends on the application. But in terms of providing strong and efficient joints in any application, welding is the best. In speed, riveting excels because in this process you do not need any skilled labour or tools, etc. For instance, to join two metal sheets, you just need to drill a hole in these sheets and then insert the rivet and deform it. The joint is completed but it is not permanent and so strong.

Performance Under Stress

As you know, welded joints are stronger than riveted joints, which is why these joints perform better under stress conditions.

Cost Comparison

In the riveting process, you just need:

- Rivets

- Rivet Gun

- A person

Another criterion is that the manufacturing costs are lower, which makes it a cost-effective joining process.

If we analyze the welding technique, we need electrodes, flux, inert gases, PPEs, etc. and a lot of initial cost. All these things make welding more expensive than the riveting process.

Are Rivets Stronger than Welds

The ultimate criteria to measure the strength or efficiency of a joint is its application. For instance, if the material is heat sensitive, such as wood, and you are using a welding process for making joints, the outcome will be a failure instead of strengthening the part. In general, welded joints are stronger than riveted joints.

Safety Considerations

There are no serious safety concerns for the riveting process. While comes up with some serious human injury concerns such as skin burns, inhaling fumes, etc.

Applications

In general, both joining processes are used extensively in many industries according to their compatibility. For making a prototype, use riveting instead of welding because it saves both time and cost. For the final design, you can use welding. Other applications of these processes are given below:

Riveting

- Aircraft Industry

- Bridge Building

- Ship Building

- Consumer Product Manufacturing

Welding

- Electrical Industry

- Construction Industry

- Defence Industry

- Oil & Gas Pipelines

- Repair of Automobile

Strength of Welded VS Riveted Ship

A ship remains in water where the chances of corrosion become even higher when the rivets are not compatible with the material. So, welding is preferable because it provides strength and permanent joints.

Why do planes use rivets instead of welds?

There are many reasons why riveting is preferable to welding in the case of planes, such as:

- Ease of inspection, maintenance and repeatability

- Resistant to fatigue cracks

- Allow stress distribution

- Lightweight

- The thickness of aircraft skin does not make welding a suitable technique

Tables of Differences Between Welding and Riveting

The following table is a summary of the above differences:

|

Aspect |

Welding |

Riveting |

|

Strength |

Stronger |

Less Strong |

|

Cost |

Higher |

Lower |

|

Speed |

Slower |

Faster |

|

Skill Required |

High |

Low |

|

Applications |

Construction, Manufacturing |

Aerospace, Automotive |

Is Welding Better Than Riveting?

As we mentioned earlier, the respective application decides which is better, the riveting or welding process. For instance, although we need strong joints in a plane, we prefer rivets because they have more advantages in that case. But in most cases, yes, welding is better than riveting because of its stronger joints and pleasing appearance.

Conditions to Choose Welding Over Riveting

The following are some of the reasons why you should choose welding over riveting.

Material Type and Compatibility

It is the most important criterion for deciding between the riveting and welding joining process. If a material is heat-sensitive and you use welding as a joining process, it will result in the loss of the material's integrity and then money.

Strength and Structural Requirements

If the application requires a high strength of the joint, you should choose the welding process.

Aesthetics and Finish

The welding provides both strength and a nice appearance in the structure.

High-Temperature Applications

Welding is a suitable joining process in high-temperature environments such as exhaust systems and heat exchangers.

Skills, Equipment, and Cost

The specialized equipment and skilled labour required for welding as compared to the riveting process while riveting is simple you do not require a training course.

Conditions to Choose Riveting Over Welding

Now, we will discuss the conditions when we should use

Material Sensitivity

Riveting sheet metal is better for heat-sensitive materials. It provides strong connections to those materials where welding is not suitable.

Joining Dissimilar Materials

In the case of welding, the main concern is the thickness of the respective parts. Welding is not suitable sometimes when the thickness of the parts becomes a problem for making joints. In such conditions, riveting excels. That's why we use riveting on planes.

Accessibility and Ease of Use

Riveting is often easier to apply in hard-to-reach areas than welding.

Non-Permanent Applications

Scenarios where riveted connections are more suitable for temporary structures or quick repairs. You can easily break the joint when it is not required; for instance, in streetlights, temporary riveted joints are made.

Cost and Time Efficiency

Riveting does not require specially trained labour or tools, etc., that's why it is a cost-effective joining process. Further, the machining costs to make a rivet are far lower than the welding tools.

Tuofa's Expertise in Welding and Riveting

Tuofa is a Chinese company which is equipped with advanced manufacturing tools. We offer both types of joining processes at reasonable costs. We have all types of welding techniques and can make riveted joints efficiently. For mass or low-level production of metalworking, you can come to us. We will deliver our products on time.

Conclusion

Welding and Riveting are joining processes in the manufacturing industries. Both processes have their applications in important industries such as construction, aerospace, automotive, medical, etc. Welding provides stronger and more permanent joints. Rivets provide temporary joints and use where welding is not accessible, as in the case of planes.

FAQs

Is Riveting Permanent or Temporary?

In most cases, Riveting provides temporary joints. You can break riveted joints when they are not required any more.

Is Riveting Cheaper Than Welding?

Yes, because in riveting you do not need any special tools or trained labour.

Which Method Offers Greater Strength?

To make very strong joints, welding is required because it fuses two metal sheets or parts into each other and makes a very strong joint.

When Should I Use Welding Instead of Riveting?

When you need strong and permanent joints, the aesthetic appearance of the joint and metal sheets is dissimilar, you should use welding instead of riveting.

Why Is Riveting No Longer Used in Some Applications?

Welding has replaced riveting in many applications because of superior strength and durability. Still, riveting is in use where weight and vibration resistance are critical.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Hydraulic Fitting Types and Their Applications: A Complete Guide

Hydraulic Fitting Types and Their Applications: A Complete Guide