How to Lock The Bolts From Loosening?

Dec 02,2022

Dec 02,2022

As a tool commonly used in fixtures, bolts are widely used, but long-term use will also bring many problems, such as loose connection, insufficient clamping force, and rusted bolts. During the processing and production of parts, the quality and efficiency of processing will be affected due to the loose connection of bolts.

Bolted connections may be subjected to all kinds of fluctuating loads under working conditions, including extremely severe vibration and shock loads. Under the action of fluctuating loads, the failure of bolted connection is usually caused by its own loosening and fatigue damage. In general, the anti-vibration loosening life of the threaded connection is longer than that of its material and structure.

The fatigue life of the structure is much shorter, and long before the fatigue failure, there has been a loosening failure of the threaded connection due to looseness, or premature fatigue failure of the connecting part and the connected part due to loosening.

The failure of bolted connections will affect the normal operation of products and equipment, and even cause serious consequences. How to prevent the loosening of bolts is one of the important tasks in the development and design of threaded fasteners.

So how to prevent the bolt from loosening? There are three kinds of anti-loosening methods commonly used in actual operation: frictional anti-loosening, mechanical anti-loosening and permanent anti-loosening. But today China Shenzhen Tuofa CNC Machining introduce these 12 comprehensive methods of bolt loosening - professional knowledge

Anti-loose purpose: to work more effectively for a long time; to improve the reliability of related workpieces.

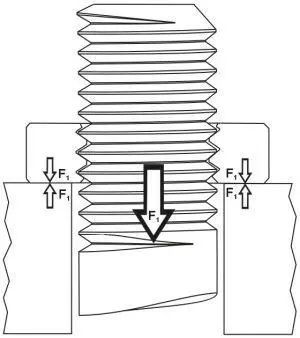

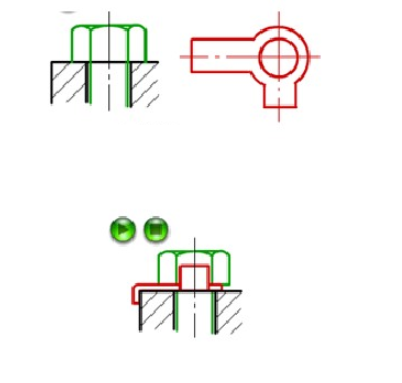

Double nut

The principle of anti-loosening nuts on the top: when double nuts are locked, two friction surfaces are generated. The first friction surface is between the nut and the fastened part, and the second friction surface is between the nut and the nut. During installation, the pretightening force of the first friction force surface is 80% of the second friction force surface.

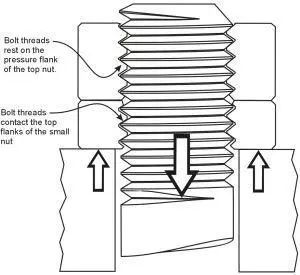

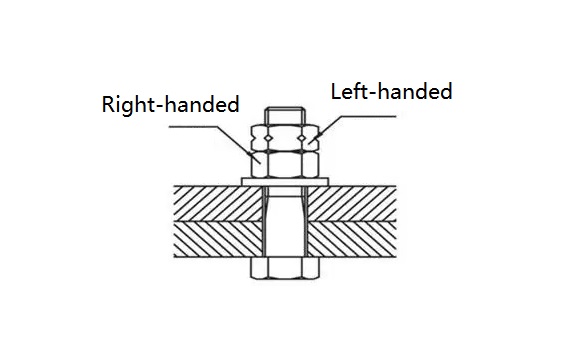

Anti-loosening principle of Down's thread: Down's thread fasteners also use double nuts to prevent loosening, but the rotation direction of the two nuts is opposite. When impact and vibration loads are applied, the friction force of the first friction force surface will decrease and disappear.

The first nut (right-handed in the figure) will have a tendency to loosen, that is, the nut rotates to the left. But the direction of rotation of the second nut (left-handed in the figure) is opposite to that of the first nut, so the loosening force of the first nut is directly converted into the tightening force of the second nut. In this way, the nut will never loosen.

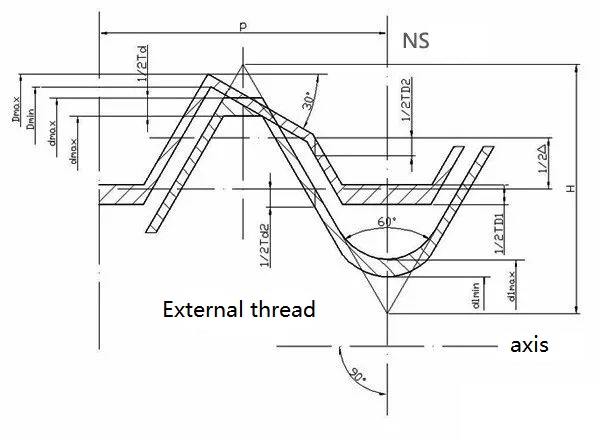

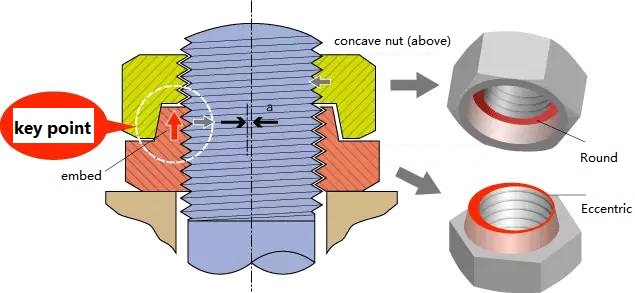

30° wedge thread anti-loosening technology

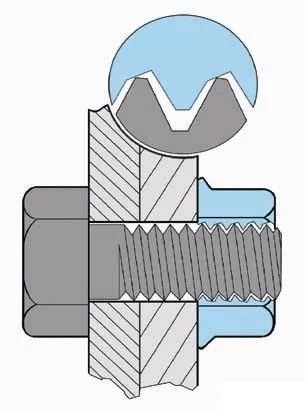

There is a 30° wedge-shaped slope at the bottom of the 30° wedge-shaped female thread. When the bolts and nuts are tightened together, the cusps of the bolts are tightly pressed against the wedge-shaped slope of the female thread, resulting in a great locking. force.

Due to the change of the angle of the tooth shape, the normal force generated by the contact between the threads is at an angle of 60° to the bolt axis, instead of the 30° angle like ordinary threads. Obviously, the normal pressure of the 30° wedge thread is far greater than the fastening pressure, so the resulting anti-loosening friction must be greatly increased.

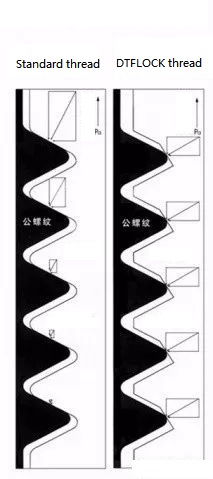

▲ Schematic diagram of DTFLOCK thread structure

From the figure below, it can be seen that the force represented by the two arrows is Pɑ, the normal pressure of the traditional 60° angle thread is P=1.15Pɑ; and the 30° wedge thread has a 30° wedge-shaped slope at the bottom of the tooth. The angle and size of the normal pressure are changed, and the normal pressure P=2Pɑ.

The ratio of the normal pressure between the 30° wedge thread and the traditional 60° thread is ≈12:7, and the anti-loosening friction force increases accordingly. The wedge-shaped surface of the 30° wedge thread can also eliminate the problems of uneven stress on ordinary threads, tripping and seizure.

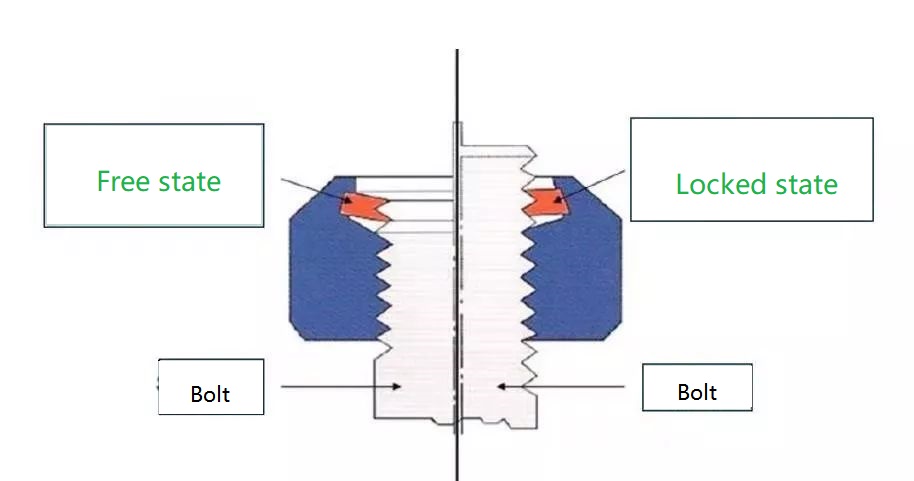

Self-locking nuts

Self-locking nuts generally lock themselves by friction. The 30° wedge thread anti-loosening we mentioned above should belong to the category of self-locking nuts.

It is divided into: high-strength self-locking nuts for road construction machinery, mining machinery, vibration machinery and equipment, nylon self-locking nuts for aerospace, aviation, tanks, mining machinery, etc., for working pressure not greater than 2atm working medium Gasoline, kerosene, water or air use the swimming self-locking nut on the product with a temperature of -50~100°C, and the spring clip self-locking nut.

▲Embedded nylon self-locking nut

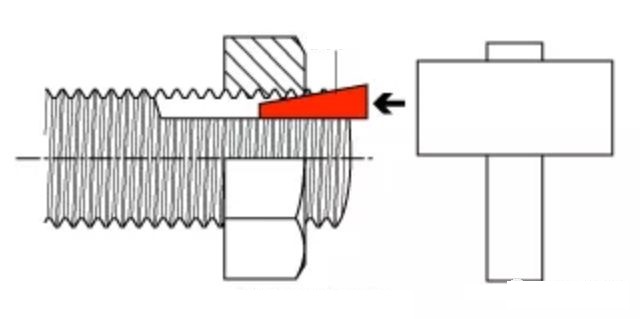

▲Insert a wedge between the nut and the screw to prevent loosening

▲Japanese Hadlock eccentric self-locking nut

|

Try Tuofa Now! Tuofa Engineer Support Team - Real human quotes are more accurate than software quotes |

Get a free quote |

Threadlocker

Thread locking adhesive is an adhesive composed of (meth)acrylate, initiator, co-accelerator, stabilizer (inhibitor), dye and filler in a certain proportion.

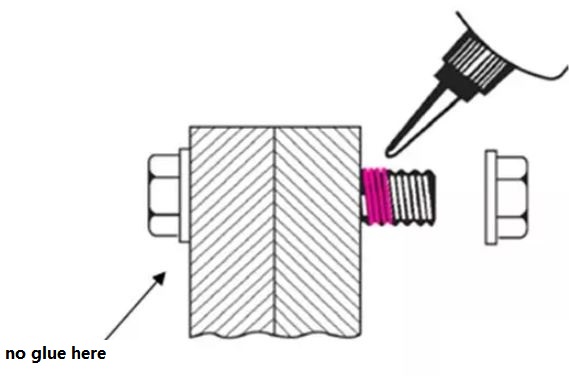

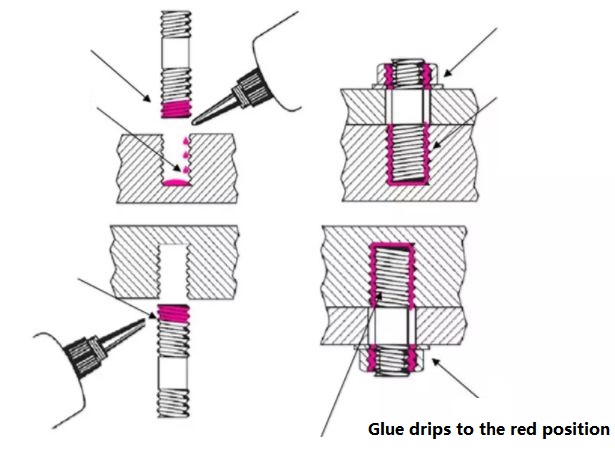

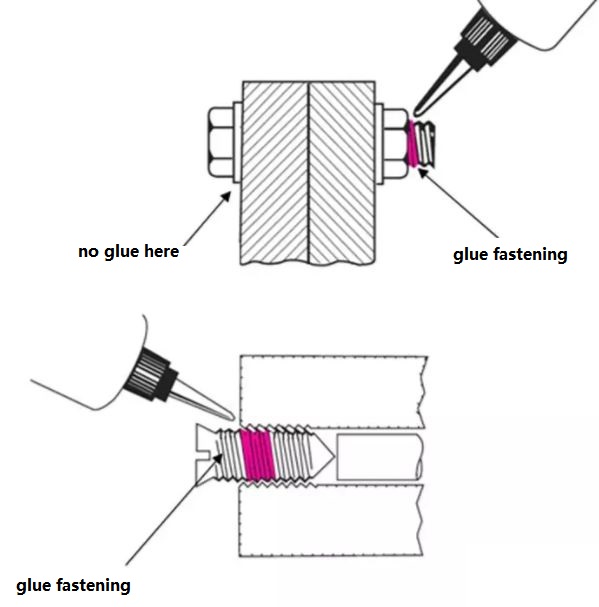

For through-hole conditions: pass the bolt through the screw hole, apply thread locking glue to the thread of the engaging part, assemble the nut and tighten it to the specified torque.

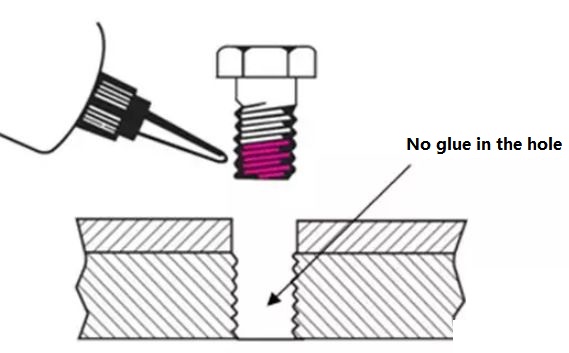

For working conditions where the depth of the screw hole is greater than the length of the bolt: apply locking glue to the thread of the bolt, assemble and tighten to the specified torque.

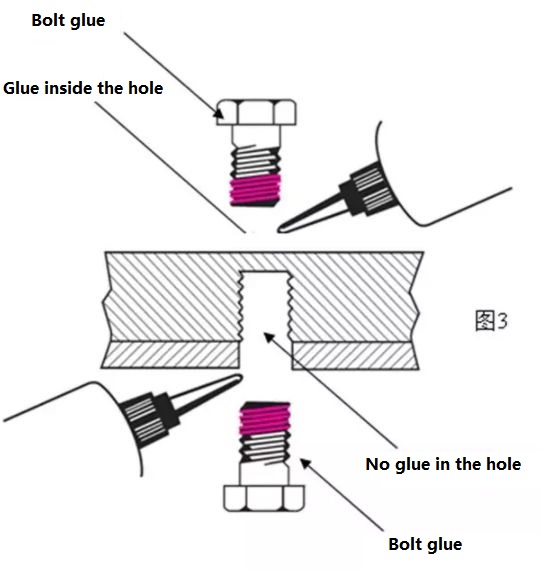

For blind hole working conditions: drop the locking glue to the bottom of the blind hole, then apply the locking glue to the thread of the bolt, assemble and tighten to the specified torque; if the opening of the blind hole is downward, just apply the locking glue It can be applied to the thread of the bolt, and no glue is required in the blind hole.

For the stud bolt working condition: the locking glue should be dripped into the screw hole, and then apply the locking glue on the bolt, assemble the stud and tighten it to the specified torque; after assembling other parts, apply the locking glue to the stud Assemble the nut and tighten it to the specified torque at the meshing part with the nut; if the opening of the blind hole is downward, no glue is needed in the hole.

For pre-assembled threaded fasteners (such as adjustable screws): After assembling and tightening to the specified torque, drop the locking glue into the thread engagement, so that the glue can penetrate by itself.

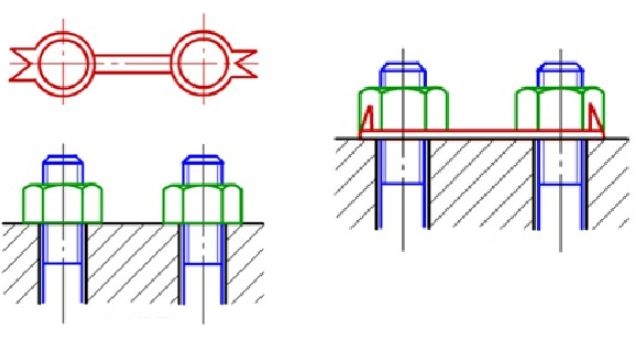

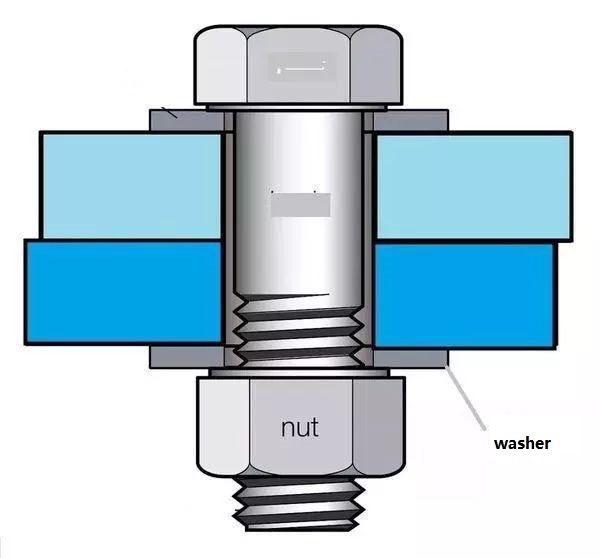

Wedge Locking Locking Double Stack Washers

The radial serrations on the outer surface of wedge lock washers engage the surface of the workpiece they contact. When the anti-loosening system encounters a dynamic load, displacement can only occur on the inner surface of the washer.

The expandable distance along the thickness direction of the wedge lock washer is greater than the longitudinal displacement that can be produced by the bolt along the thread.

The other existing anti-loosening methods are completely different. The wedge-type anti-loosening tightens the bolts by clamping force rather than frictional force.

The 120-year-old HEICO-LOCK wedge anti-loosening system products include wedge lock washers, RING-LOCK wedge washers and wedge lock nuts. The main materials are carbon steel coated with Dacromet and 316 Stainless steel, stainless steel materials such as 254SMO, C276 and 718 are also widely used.

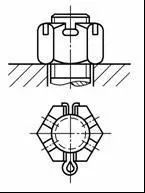

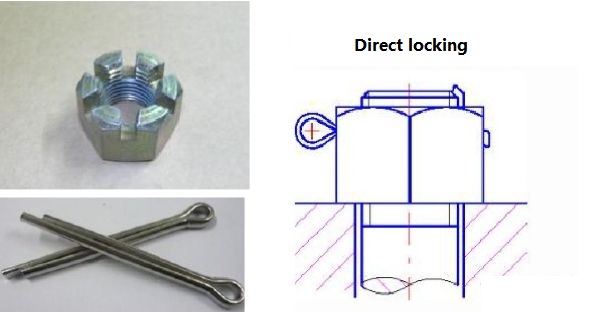

Cotter pins, slotted nuts

After the nut is tightened, insert the cotter pin into the nut groove and the hole at the end of the bolt, and open the tail of the cotter pin to prevent the relative rotation of the nut and the bolt.

The installation form of cotter pin is as follows:

Slotted nuts are used in conjunction with threaded rod hole bolts and cotter pins to prevent the bolts from rotating relative to the nuts.

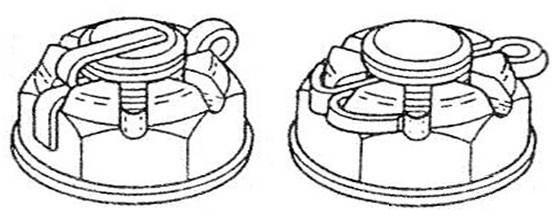

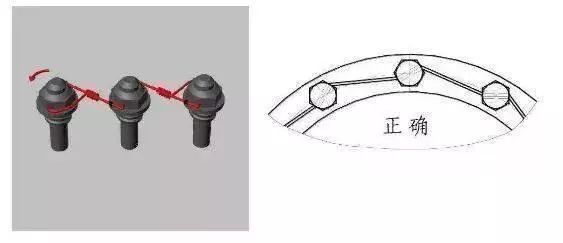

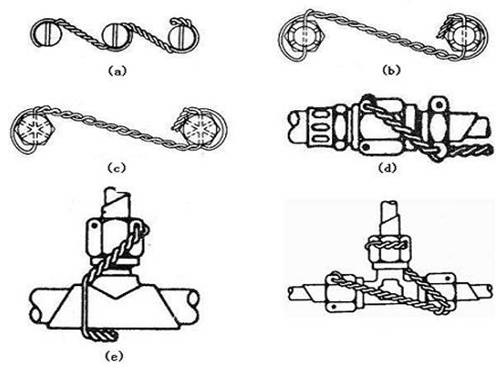

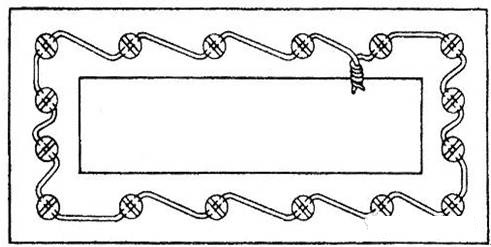

Series wire, anti-loosening

The series steel wire anti-loosening is to pass the steel wire into the hole of the bolt head, connect the bolts in series, and play the role of mutual containment. This loosening method is very reliable, but it is troublesome to disassemble.

This method of anti-loosening is often used in aircraft and rockets.

Single-strand steel wire is generally used in small screw groups with close spacing or places that are difficult to reach, as shown in the figure.

Stop washer

After the nut is tightened, the single-ear or double-ear stop washer is respectively bent and tightly attached to the side of the nut and the connecting piece, so that the nut can be locked. If the two bolts need to be double locked, a double brake washer can be used to make the two nuts brake each other.

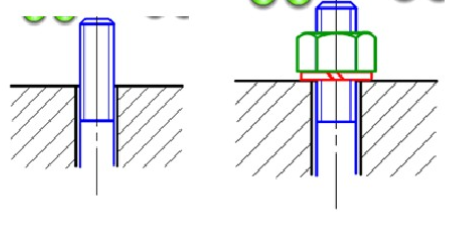

Spring washer

The anti-loosening principle of the spring washer is that after the spring washer is flattened, the spring washer will generate a continuous elastic force, so that the threaded connection pair between the nut and the bolt will continue to maintain a frictional force, generate a resistance torque, and prevent the nut from loosening.

At the same time, the sharp corners of the opening of the spring washer are respectively embedded in the surface of the bolt and the connected part, so as to prevent the bolt from rotating relative to the connected part.

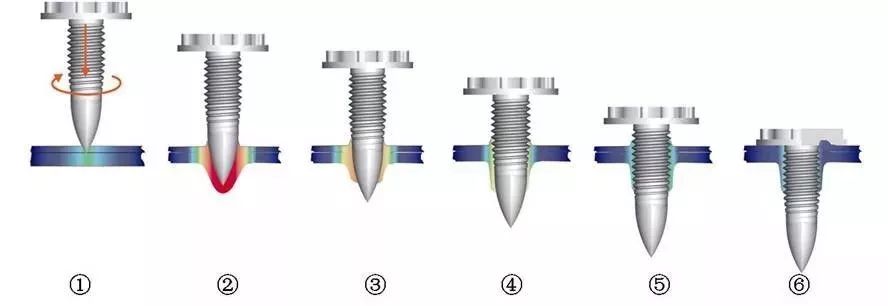

Hot melt fastening technology

Hot-melt fastening technology does not require pre-drilling, and can be directly tapped to achieve connection under the closed profile, which is widely used in the automotive industry.

This hot-melt fastening technology is a cold forming process that conducts the high-speed rotation of the motor through the central tightening shaft of the equipment to the plates to be connected after friction and heat to produce plastic deformation, and then self-tapping and screwing.

The hot melt fastening process steps and process include six stages: rotation (heating)→penetration→through hole→tapping→threading→tightening.

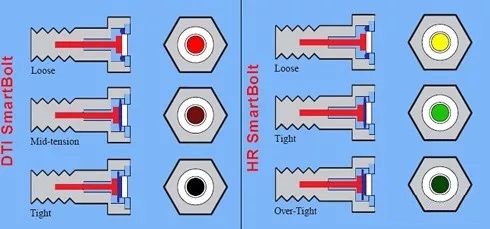

Color changing bolt

Smart color-changing bolts, to be precise, this is a kind of induction bolt called Smartbolt. The bolt head of the induction bolt has an induction plate, and the tighter you tighten it, the darker its color will be.

When the intensity reaches 90%, it turns from yellow to green, and when it reaches 100%, it becomes black.

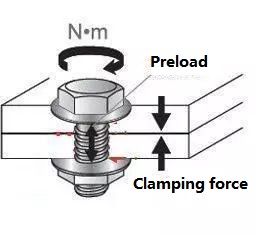

Preload

The High-strength bolt connections generally do not require additional anti-loosening measures, because high-strength bolts generally require a relatively large pre-tightening force, such a large pre-tightening force creates a strong pressure between the nut and the connected parts, This pressure creates a frictional torque that stops the nut from turning, so the nut does not loosen.

I wonder if you have learned the classic anti-loosening design of the above 12 kinds of bolts. Of course, after mastering the anti-loosening design of the bolts, the tightening method and torque distribution during tightening should also be considered when manually clamping the bolts.

| Let's Start A New Project Today |

| Get a Free Quote |

Summarize

- As long as the pre-tightening force is sufficient to meet the requirements, as long as the clamping length is not too short (such as lk≥3d), even if there is a certain vibration load, the bolt will generally not loosen itself.

- The combination of good bolted joint design, proper clamping force development, and proper bolt lockouts can reliably secure bolted joints to meet the many loosening challenges presented here.

- A good bolted connection will be designed with the proper size and type of bolts and nuts, and specify the optimum tension to achieve the clamping force necessary to maintain the integrity of the connection.

- Proper clamping force in an application requires the correct level of tension (preload) in each bolt to be maintained at that level throughout its service life.

Tuofa CNC machining top-level manufacturing capabilities

Good design comes from communication, and finding a good supplier starts with you contacting info@tuofa-cncmachining, so do you want to know more about our resources, whether it is part design or ordering samples, we are competent.

Our complete industrial manufacturing services include CNC machining, sheet metal manufacturing, and 3D printing. We believe that Tuofa's manufacturing capabilities will allow you: one online ordering experience, 100 million sharing.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Chamfer VS Fillet: The Cost is in The Details

Chamfer VS Fillet: The Cost is in The Details