Chamfer Vs Bevel: The When, Why, And How of The Connecting Parts

May 15,2023

May 15,2023

Creating objects with machines results in sharp corners. These are available in different shapes with edges and surfaces. Machines use chamfers and bevels to make the design interesting. Thus, it is necessary to learn about their qualities, properties, and other aspects. This article will teach us how to use them.

Chamfers vs Bevel is a famous discussion among mechanics and designers. Making the right decision can improve or ruin the design. Also, the designer must learn about the cost and time to create the part. You have come to the right place to familiarize yourself with chamfers and bevels.

What is a Bevel?

Let us begin the chamfer vs bevel conversation! Are you interested in learning what a bevel is? It is a corner edge whose angle is less than 90 degrees. You will find bevel cuts in the following objects.

- Baseboards

- Cupboards or cabinets

- Mirrors

- Furniture

The part takes its name from the French word “baivel.” Its root word is “bayer.” The word means to yawn. And it perfectly represents the bevel angle. Bevel was most used in the 1600s as a verb. It is because bevels were trending in architecture.

Bevels enhance the object’s appearance. They are used for décor purposes. Also, bevels prevent injuries. The part results in soft corners. There are no sharp turns that can cause cuts or bruises if someone bumps into furniture or mirrors.

A bevel has a certain angle that will connect two pieces. It can be a slope too. Most bevels are created from wood for customized results. Also, a bevel is used to soften the edges. It will cover sharp turns on the counter and tabletops. Bevels are very common in kitchens and bathrooms.

You will also notice a bevel on the baseboard. They are present on roof trims too. Bevels come in many different shapes and sizes to add eye appeal. But now you know the bevel edge also serves a deeper, safer purpose!

A bevel tool is used to create the slant/edge. The tool does not have an official name because of its diverse use. Most beginners create a bevel with a blade or knife. The trick is to trance the angle while cutting the material.

A bevel rule has two arms attached to a hinge. It also has a hidden protractor to measure the bevel angle. It is a very important tool in architecture to measure the angles exactly. It helps sketch and draw. Designers, architects, and artists use the tool regularly.

Bevels enhance the object’s appearance. They are used for décor purposes. Also, bevels prevent injuries. The part results in soft corners. There are no sharp turns that can cause cuts or bruises if someone bumps into furniture or mirrors.

A bevel has a certain angle that will connect two pieces. It can be a slope too. Most bevels are created from wood for customized results. Also, a bevel is used to soften the edges. It will cover sharp turns on the counter and tabletops. Bevels are very common in kitchens and bathrooms.

You will also notice a bevel on the baseboard. They are present on roof trims too. Bevels come in many different shapes and sizes to add eye appeal. But now you know the bevel edge also serves a deeper, safer purpose!

A bevel tool is used to create the slant/edge. The tool does not have an official name because of its diverse use. Most beginners create a bevel with a blade or knife. The trick is to trance the angle while cutting the material.

A bevel rule has two arms attached to a hinge. It also has a hidden protractor to measure the bevel angle. It is a very important tool in architecture to measure the angles exactly. It helps sketch and draw. Designers, architects, and artists use the tool regularly.

What is Chamfer?

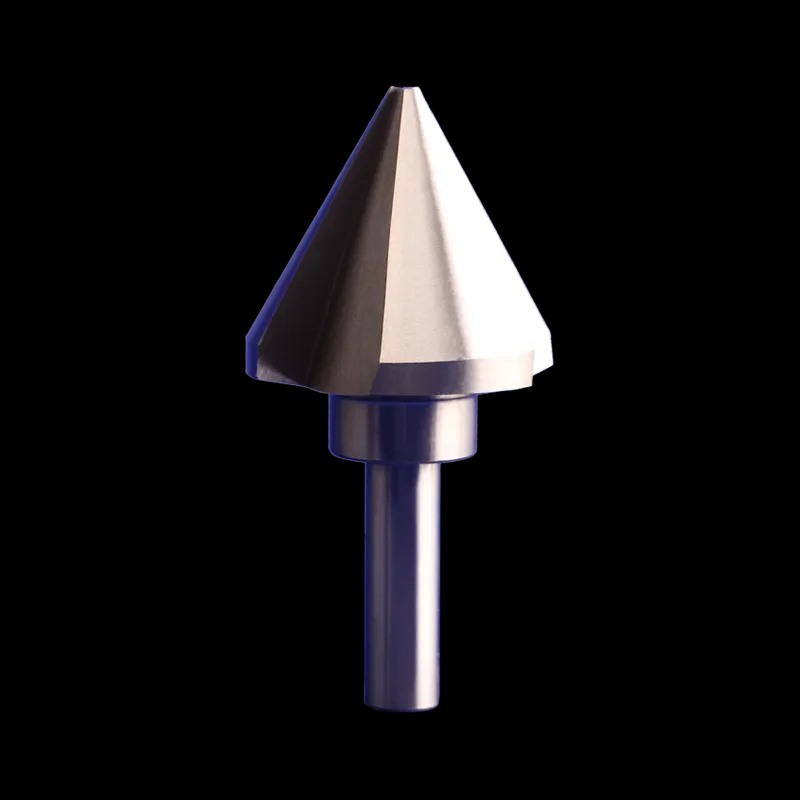

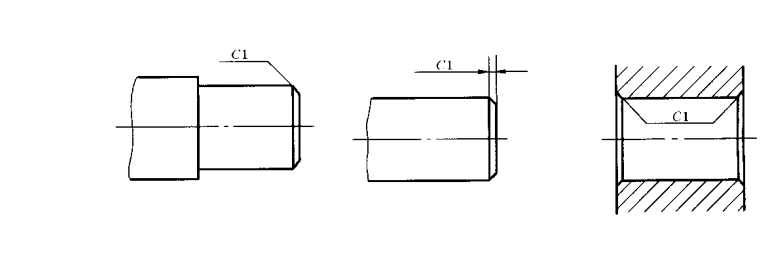

A chamfer looks a lot like a bevel. It is made from cutting material. The chamfer’s shape differs from the bevel because it has a 45-degree angle. The mathematics result in an octagonal shape. Chamfer is common in manufacturing and engineering. Chamfer planes are used to create the part. Also, chamfer plans are used.

Chamfer has an eye-catching appeal to it. Yet, they are also used for structural purposes too. You can identify chamfers in circuit boards and mirror designs. A chamfer has an inner and outer layer focusing on the following advantages.

Difference Between Bevel and Chamfer

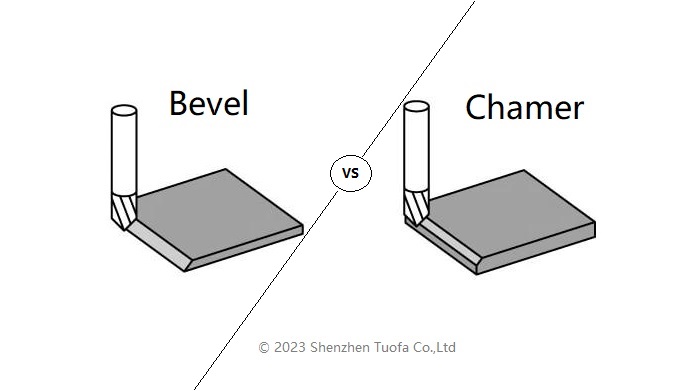

Bevel vs Chamfer: Edge

Chamfered edges are flat, angled cuts along the corners or edges of an object. They are used to make sharp corners smoother, so they don't hurt or cause injuries. Chamfered edges also make it easier to put parts together or take them apart.

Beveled edges, on the other hand, are sloping surfaces that go from one edge to another. They are mainly used to make things look nicer and more attractive. Beveled edges add decoration and make objects visually interesting.

Bevel vs Chamfer: The Tools

Automated machinery will measure the beveled surface. The tool is unique. It comes with horizontal and vertical settings. Chamfer milling does not need special machinery.

A chamfer tool has a dial to measure the angle accurately. Also, it is used to improve the slope gradient and size. A chamfer tool saves time because it is helpful in chamfer and bevel measurements.

Unfortunately, a bevel tool is reserved for bevel only. It has two blades attached with an angle measurer. A chamfer tool has units to measure the length. The user can measure one side of the raw material or both sides.

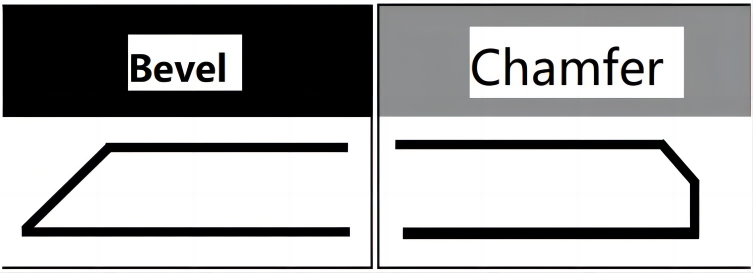

Bevel vs Chamfer: Angle

A bevel edge has a slope that joins two similar-looking raw material surfaces. A chamfer has an angle of 45 degrees between two opposite pieces of material. A chamfered edge has a shape of an octagon. On the other hand, the bevel’s slope looks like a parallelogram.

Bevel vs Chamfer: The result

The bevel meaning does not mention always using a tool. Also, removing materials to create a bevel edge is not required. Yet, some manufacturing process result in a slanted edge between two same-looking materials. The slant is called a bevel.

Chamfer requires removing the material. Hand-held tools or machinery are used. The process softens the edges. Chamfer improves the appearance and avoids injuries as well.

Bevel vs Chamfer: Other Differences

- Chamfer slope has 45 degrees. Bevel has a custom slope that is not 45 or 90 degrees.

- A chamfer needs a milling machine. A bevel needs a bevel tool.

- You can measure a chamfer using a gauge, ruler, or dial. A bevel needs a protractor for accurate measurement.

What are the Advantages and Disadvantages of Chamfer?

Following are some of the advantages of chamfer

Promotes safety

Eliminate sharp corners to focus on safety. Sharp edges will not hurt workers, employees, and loved ones.

Becomes a guide

Chamfers are a teaching experience. It represents the person’s skills and crafts.

Pleasing to the eyes

Thirdly, chamfers also make items and parts very beautiful. It engages with the audience. Chamfers increase the chances of a sale.

Prevents future damage

Steel is chamfered before it goes into protection. Chamfering is an essential step before heat is applied to the metal. The procedure releases stress. It reorganizes internal structure too. Chamfers remove cracks. Steel does not crack in the future.

Why are Chamfers not Always the Best Idea?

Chamfers will depreciate over time. The chamfer edges become unappealing and ruin the design.

Chamfers usually require an expert. The individual must study and understand chamfers before creating them.

Do Chamfer and Bevels Impact the Machining Parts?

Let’s continue with the bevel vs chamfer discussion. Yes, the parts affect the item in many different ways. Here are a few:

Handling the object

Bevels and chamfers make the product easier to handle. Chamfers are installed on the edges of the items to soften the edges. As a result, furniture transports without accidents.

Bevel will soften the edge facing the user. Yet, it will sharpen the edge facing away from the individual. Because bevels sharpen and soften the item, they are inaccurate for objects needing transportation.

Bevels are used to design the perfect fit with the base material. It improves the layout and the features.

Production cost

Bevels and chamfers are created after completing the item. They use additional machining time. It can make the production process longer by five to ten percent of the time. Also, the machine will need an employee to operate it. It will use more electricity which increases electricity.

Businesses now add bevels and chamfers to the process of manufacturing. The costs after production are removed. Thus, reducing expenses.

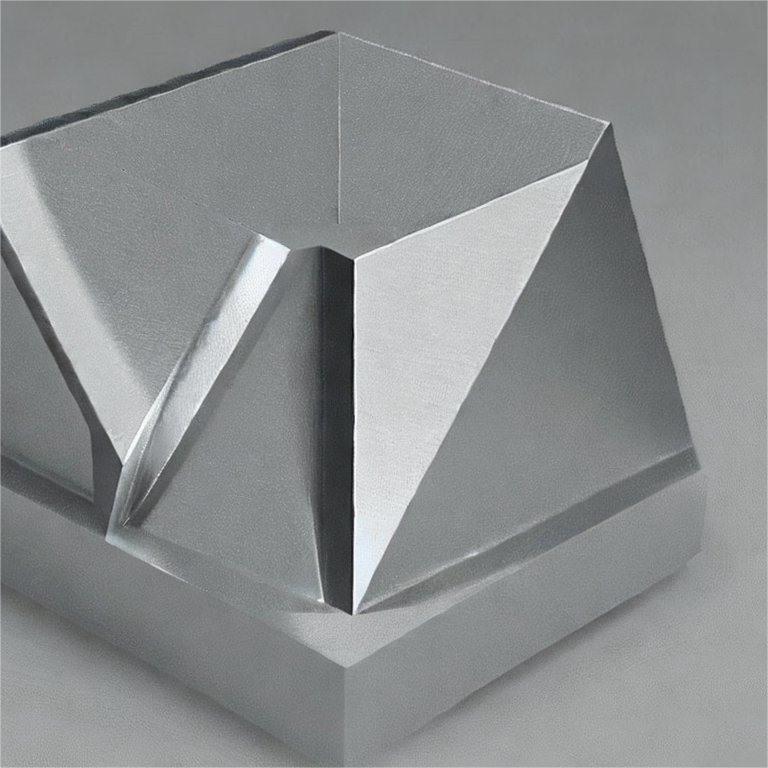

Item

The final piece does not have sharp turns or edges because of chamfers and bevels. The additions make the item more appealing. Chamfers are used mostly in woodworking projects. They result in elegant outcomes and smooth edges. Bevels and chamfers are also common in jewelry to improve the appearance and the overall design.

The strength of the design

Chamfers flatten the design because it removes sharp corners. Pointy edges can cause the structure to crack from the everyday weight. Thus, the item weakens and falls apart.

A bevel focuses on the design and improves the surface area. The item can endure heavy objects. It is the go-to strategy for joining pieces.

The final product

Bevels and chamfer remove material from the item. The object reduces in weight. It shrinks because of smart design. Also, bevels and chamfers simplify a difficult design. The parts fit into each other nicely. For example, attaching a bevel to two wooden slabs increases the surface area.

Bevel vs Chamfer: Which one to Choose?

Congratulations on knowing the differences! Are you curious about which one to use in chamfer vs bevel? This section is for you.

Structure

A chamfer plain is not always the right answer to stabilize joints. A chamfer has less surface area. It means the chamfer will have less material. As a result, the chamfer will not strongly bond with the base material.

Bevel seeps into the design. It has enough surface area to bond with the base material. Bevel introduces strength and does not weaken the design. The structure’s thickness also increases. The bevel is the correct choice if the individual wants a strong bond.

Visual

A finished item from the industry line has sharp edges. The rough corners make it difficult to hold, lift, and transport. It can hurt the workers and scratch the machinery. Industries use chamfers in many items, such as glasses and mirrors. The vertical chamfers make the item safer for everyone. The designs look beautiful too.

Chamfering also has bolts. The nuts make it easy to handle the items. Also, a chamfer piece increases strength. There are no more sharp corners that will crack. A bevel makes the edges sharper. An object with bevels will crack easily because the edges are thin.

Time and money

Bevels and chamfers need time to make. Also, creating these pieces adds to the cost of production. Chamfers and bevels reduce output. It can take a longer time to produce many times. The cost and time requirements can make the item very expensive. Only add them when the structure demands it.

Raw material

Complex parts need bevels to attach to the design successfully. Bevels are present in slabs and other woodworking. Bevels ensure that woods and materials are easy to layer.

A blunt chamfer tip makes it easier to fit into the design. The material is not damaged.

Summarize

We have now learned that chamfer and bevel are a lot similar. However, they are different in use. Chamfers increase the strength of the item. Bevels improve the design.

Bevels and chamfers need additional machining time. It increases expenses. Therefore, the parts are added where they are necessary. The step requires understanding the design.

Chamfers and bevels are not necessary If you enjoy doing woodworking as a hobby. It will shorten the time to create objects. Also, you can save money.

Choose Tuofa for Design and Production Services!

Tuofa is a brilliant team of engineers, programmers, machining experts, sale team to help clients with their orders. We are skillful and provide training to our employees every month. Tuofa works closely with cars, electronics, and robotic industries. So, hire us today for design input. Tuofa offers excellent production services.

The company exports to more than 50 countries. Tuofa is part of a growing network with clients in Australia, South America, and Europe. You can reach us using email. Call us at +86-13828703141. Clients can also contact us through Skype, WhatsApp, and WeChat.

FAQs about Bevel and Chamfer

Is a chamfer always 45 degrees?

A chamfer is a small piece of material that connects two faces of the primary objects. The angle of the bevel is usually 45 degrees. It is the angle between the original surfaces. A Chamfer of 45 degrees creates an isosceles triangle. It is the correct length to join two equal sides of the material. What is the use of PVC chamfer?

Homeowners can use PVC chamfers to inspect pipes without requiring official help. Chamfers do not complicate the fixing process. Experts use PVC chamfers to identify if the damage is on private or public property. PVC chamfers will also identify sewers. Repairs are cheap too. Chamfers are helpful in different systems. You can weld the metals to make molds. However, cast iron and steel welding will not work for heavy equipment. It will not absorb stress. Chamfering vs filleting: What is the difference between?

Fillet is to replace the original edge with an arc. On the other hand, a chamfer will join two pieces of raw material at an angle. Fillets are used in structures that will endure the weight. Therefore, they add strength. A chamfer is ideal for joining materials that must be connected. Chamfer vs bevel vs fillet

A fillet is present inside the corner. Also, you will notice a fillet on the outside of the corner in assembled pieces. Secondly, a bevel has a slope. It can be vertical or horizontal. Lastly, a chamfer is a 45-degree angle piece that connects the edges of the design. These three components are very different. Yet, they look similar. |

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Crankshaft VS Camshaft: Understanding the Key Differences

Crankshaft VS Camshaft: Understanding the Key Differences