What is the Density of Brass? A Comprehensive Guide

Jun 28,2024

Jun 28,2024

Brass is an essential material widely used in various industries due to its excellent properties. These properties include corrosion resistance, electrical conductivity, and machinability. Understanding the density of brass is crucial for professionals in the manufacturing and mechanical engineering fields. At Tuofa, we specialize in precision CNC machining. We have extensive knowledge of material properties. This ensures the highest quality and performance in all our products.

What is Brass?

Brass is an alloy primarily composed of copper and zinc. The ratios of these two elements can vary, resulting in different types of brass with distinct properties. Here are some common types of brass used in industries:

|

Type of Brass |

Composition |

Properties |

|

Alpha Brass |

Contains less than 35% zinc |

Ductile, can be cold worked, good for bending and deep drawing |

|

Alpha-Beta Brass (Duplex Brass) |

Contains 35-45% zinc |

Combines good strength with ductility, suitable for hot working |

|

Beta Brass |

Contains 45-50% zinc |

Hard and strong, less ductile, suitable for hot working |

|

Lead Brass (Leaded Brass) |

Contains up to 3% lead |

Excellent machinability, suitable for high-speed machining processes |

|

Tin Brass |

Contains a small percentage of tin |

Improved corrosion resistance, suitable for marine and naval applications |

|

Aluminum Brass |

Contains a small percentage of aluminum |

High strength and corrosion resistance, particularly in seawater |

Why Density Matters

Density is a fundamental property in material science that indicates how much mass a material contains in a given volume. Knowing the density of brass is crucial for various applications in manufacturing and engineering, as it affects the material's strength, weight, and performance.

Importance of Density in Manufacturing and Engineering

Density is crucial in manufacturing and engineering for material selection, weight calculations, and quality control. It ensures components are strong, lightweight, and consistent, optimizing performance and reliability.

Material Selection

Helps in choosing the right type of brass for specific applications.

Weight Calculations

Essential for designing components where weight is a critical factor.

Quality Control

Ensures consistency and reliability in production processes.

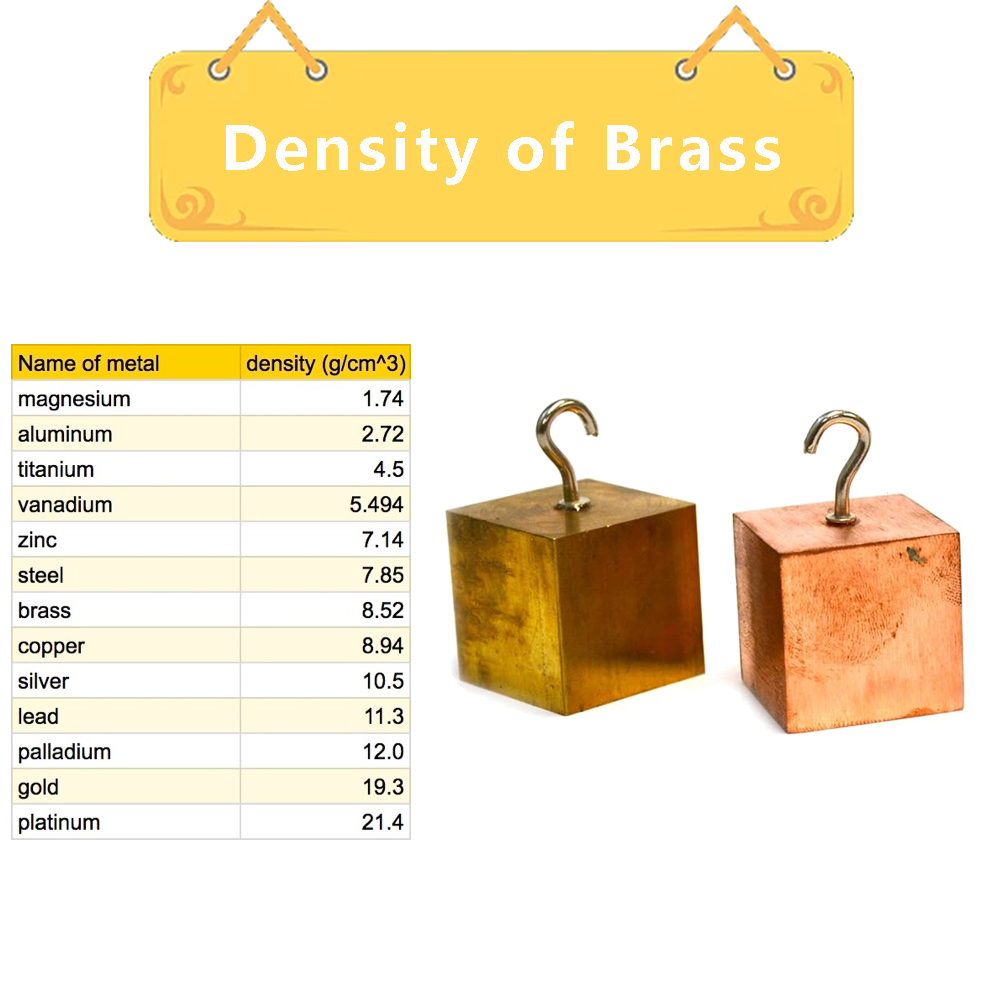

Density of Brass

The density of brass typically ranges from 8.4 to 8.73 g/cm³, depending on its composition. Factors that can affect the density include the ratios of copper and zinc and the presence of other alloying elements like tin and aluminum.

|

Type of Brass |

Density (g/cm³) |

|

Yellow Brass |

~8.47 |

|

Red Brass |

~8.75 |

|

Naval Brass |

~8.4 - 8.7 |

Density of Common Brass Alloys

The density of brass varies based on its composition. Here are the densities of some common brass alloys:

Yellow Brass

Yellow brass, with its vibrant color and good mechanical properties, has a density of around 8.47 g/cm³. It is commonly used in applications such as plumbing fittings and musical instruments.

Red Brass

Red brass, known for its durability and corrosion resistance, has a density of approximately 8.75 g/cm³. It is often used in applications requiring high strength and resistance to wear, such as in valves and gears.

Naval Brass

Contains about 60% copper, 39% zinc, and 1% tin, with a density ranging from 8.4 to 8.7 g/cm³.

Measuring the Density of Brass

Measuring the density of brass involves determining its mass and volume accurately. Here are common methods used:

Archimedes’ Principle

Archimedes' principle is a practical method for measuring the density of brass. Here is a step-by-step guide:

Equipment Needed

A balance, a water container, and a sample of brass.

Procedure

Measure the mass of the brass sample using the balance.Submerge the brass sample in water and measure the displaced water volume.Calculate the density using the formula: Density = Mass / Volume Displaced.

Density Meters and Hydrometers

Density meters and hydrometers are instruments that provide accurate density measurements. Each has its advantages and limitations:

Density Meters

Provide high precision but can be expensive and require calibration.

Hydrometers

More affordable and easy to use but less precise than density meters.

Mass and Volume Calculation

For regularly shaped brass samples, density can be calculated by measuring the mass and volume directly:Measure the mass using a balance.Measure the volume by calculating the geometric dimensions.Use the formula: Density = Mass / Volume.

Factors Influencing Brass Density

The density of brass can be influenced by several factors, including its composition, manufacturing processes, temperature, impurities, and microstructure. Understanding these factors is crucial for achieving desired material properties in various applications.

Manufacturing Processes

The manufacturing processes, such as casting, extrusion, and rolling, can significantly affect the density of brass.

Casting

May introduce porosity, leading to a lower density.

Extrusion and Rolling

Typically result in a more uniform and higher density material.

Temperature and Impurities

Temperature variations and the presence of impurities can also impact the density of brass.

Temperature

Higher temperatures can cause expansion, reducing density.

Impurities

Elements like lead or tin can alter the density, either increasing or decreasing it depending on their concentrations.

Microstructure and Defects

The microstructure and presence of defects, such as voids or inclusions, play a crucial role in determining the density of brass.

Microstructure

A fine, uniform microstructure generally indicates a higher density.

Defects

Voids and inclusions reduce the overall density and can affect mechanical properties.

Applications of Brass Based on Density

The density of brass plays a significant role in determining its suitability for various applications. Different types of brass, with their unique densities and properties, are used across diverse industries.

Industrial Applications

Different types of brass are used in various industrial applications based on their density and other properties.

Manufacturing

Brass is used in the production of components like bearings, bushings, and gears.

Plumbing

Due to its corrosion resistance, brass is ideal for plumbing fittings and fixtures.

Electrical Fittings

Brass's excellent electrical conductivity makes it suitable for electrical connectors and terminals.

Artistic and Decorative Uses

Brass is also popular in artistic and decorative applications due to its aesthetic appeal and workability.

Musical Instruments

Brass is commonly used in wind instruments like trumpets and trombones.

Sculptures

Its malleability and attractive finish make brass a favored material for sculptures.

Decorative Items

Brass is used in the creation of decorative objects such as candlesticks, ornaments, and jewelry.

Conclusion

Understanding the density of brass is essential for selecting the right type for specific applications. This ensures optimal performance and reliability. At Tuofa CNC machining services in China, we have the expertise to assist you in choosing the appropriate brass type for your needs. We leverage our precision CNC machining capabilities to deliver high-quality, consistent products.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Bead Blasting VS Sandblasting: A Comprehensive Comparison

Bead Blasting VS Sandblasting: A Comprehensive Comparison