Is Carbon Fiber Stronger Than Steel? Strength and Weight

Oct 23,2024

Oct 23,2024

2060

2060

Carbon fiber and steel have different qualities and applications. Carbon fiber hybrid materials have just recently been used in place of steel, and their strength is already being compared to high-strength steel. This article will investigate the benefits of carbon fiber over steel in various applications.

Is Carbon Fiber Stronger Than Steel?

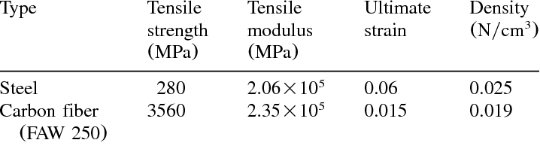

The following section presents you a comparison of the different properties of Carbon Fiber steel:

Tensile Strength Comparison

Steel has a tensile strength of 280 MPa but the carbon fiber comes up with 3560 MPa i.e. ~12 times stronger than steel.

Compressive and Flexural Strengths

Flexural strength is the resistance to bending or deformation and compressive strength is the resistance to reduction in size due to applied forces like crushing.

Carbon fiber is weaker against compressive forces but excels in flexural forces against bending forces.

Is carbon fiber the strongest material

Graphene is the strongest material in general. But if it is concerned with strength-to-weight ratio, then the carbon fiber is the strongest.

What is Carbon Fiber?

Carbon fiber, as the name implies, is composed of carbon atoms that are linked together in a crystalline manner via covalent connections. It is commonly used in the form of hybrid material i.e. Carbon fiber reinforced polymer (CFRP).

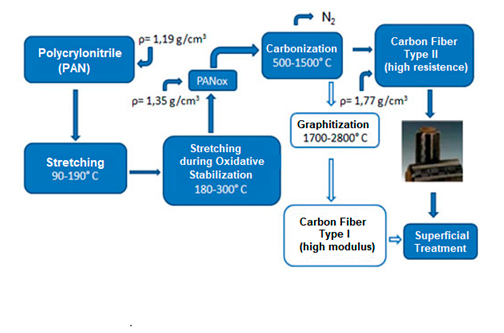

Composition and Manufacturing Process

Carbon fiber is mainly produced from PAN (Poly Acrylo Nitrile) as the following figure shows. Then the carbonization process is performed to eliminate any non-carbon materials. The final composition of Carbon fiber is 90% carbon.

https://www.youtube.com/watch?v=E-XLqrASMh0

Key Properties of Carbon Fiber

The main property of its excessive use in aerospace is the strength-to-weight ratio. Other key properties include Carbon fibre’s structural integrity, tensile strength, lightweight, fatigue and corrosion resistance.

6666

What is Carbon Fiber and Steel used for

Carbon fiber is used in the aerospace industry, racing cars and sports equipment.

While Steel is used in construction, manufacturing and transportation industries.

Carbon fiber vs Steel Driveshaft

The driveshaft is a part of an automotive car. Manufacturers like steel for making driveshafts because it is not expensive. It’s a heavy material but due to its affordability it can be repaired, that’s why steel is better for driveshafts. Carbon is used when the main concern is about weight.

Carbon fiber vs steel toe boots

Steel is considered as best choice for toe boots because it is cheaper and offers good compressive strength. Carbon fiber is not common for making toe boots as it is very expensive.

Carbon fiber vs Steel Exhaust

Heat exhaust made of carbon composites are lightweight but thermal conductivity is poor which causes a lack of heat dissipation. Since thermal conductivity and durability are important factors to be considered that’s why steel is more favorable than carbon fiber.

Carbon fiber vs steel bike

The common material is steel, but carbon fiber is a very good and expensive choice. Carbon fiber is used only for those bikes which need lightweight and high strength like racing or mountain bikes.

What is Steel Made of?

Steel is mostly made of Fe and C ~0.02% - 2.1%. Other alloying elements including Mn, Cr, Ni, Mo, and Si are added for different properties.

Is Carbon Fiber more Expensive than Steel

Steel is the most produced metal than any other. Carbon fiber is not as common as steel. Its raw materials and production processes are expensive which makes it a limited material for any application.

Advantages and Disadvantages of Carbon Fiber and Steel

Advantages of Carbon Fiber

- Strength-to-weight ratio

- Lightweight

- Fatigue resistance

- Higher stiffness

Disadvantages

- Complex Manufacturing Process

- Expensive

- Brittle

Advantages of Steel

- Tough and Durable

- Corrosion resistant

- Higher thermal conductivity

- Cheaper than Carbon fiber

Disadvantages

- Higher thermal expansion rate

- Heavier

Carbon Fiber vs Steel: Weight Comparison

Carbon fiber is approximately 5 times lighter than steel as its density is 1.75 – 2 g/cm3 and the density of steel is 7.85 g/cm3.

How heavy is carbon fiber?

Density is the main factor in checking whether the material is heavy. This density shows it is a lightweight material as compared to commonly used materials like steel or Al.

Density and Material Weight Differences

Density:

Mass per unit volume and unit is g/cm3.

Weight:

W = m.g

m= mass, g= gravity

Force exerted by gravity on the object. The unit is Newton (N).

How Weight Impacts Applications

Weight affects the speed of the vehicle and fuel efficiency. Lightweight materials are effective in increasing the speed of vehicles with a reduction of fuel.

Carbon Fiber vs Steel: Durability and Resistance

In durability and thermal resistance, steel excels while in the case of corrosion resistance and strength carbon fiber is superior to steel.

Corrosion Resistance in Different Environments

Mostly stainless steel is used for corrosion resistance because of its low cost as compared to its features. But the conditions which are very severe like high temperatures and salts in a rocket nozzle, carbon fibre is more useful.

Fatigue Life and Impact Resistance

Carbon fiber offers higher fatigue resistance than steel but lacks impact resistance due to its brittle structure.

Carbon Fiber vs Steel: Thermal Properties

Carbon Fiber has poor thermal conductivity but excellent resistance to thermal expansion as compared to steel.

Fire Resistance

Steel provides better fire resistance because carbon fiber has epoxy in its composition which is flammable.

Thermal Expansion and Conductivity

Steel has higher Thermal expansion and thermal and electrical conductivity than carbon fiber.

Temperature Resistance in High-Stress Applications

Steel is considered best for temperature resistance in high-stress applications. Carbon composites involve resin in their composition which is flammable.

Carbon Fiber vs Steel: Cost and Availability

Steel has high availability but low cost due to the easily available raw material and easy manufacturing process as compared to Carbon fiber.

Cost of Raw Materials

Polyacrylonitrile is expensive itself because in its pure form, it is not stable. A further process is done like stabilization to make it stable for the next phase to 99% pure produce carbon fiber.

Manufacturing and Machining Costs

Carbon fiber has higher manufacturing and machining costs than steel.

Lifecycle Cost Analysis

Lifecycle costs include the production, machining, maintenance and recycling costs. According to that cycle, carbon fiber is far more expensive than steel.

FAQs

Is carbon fiber stronger than steel in cars?

Yes, carbon fiber is used in the form of carbon fiber composites in formula cars as it is far stronger and light than steel.

Is there a material stronger than carbon fiber?

Graphene is the strongest material ever produced.

Does Carbon fiber break easily?

It depends on the direction of applied forces. Carbon fiber has comparatively low compressive strength and fails in a brittle way.

Is Carbon fiber more expensive than titanium?

Yes, due to its raw materials and manufacturing costs, carbon fiber is more expensive.

Carbon fiber vs steel vs stainless steel

Carbon fiber is lightweight, high strength but expensive material and fails in a brittle way.

Steel is cost-effective, and has good strength but corrosion is the issue.

Stainless steel is durable and corrosion-resistant.

Can carbon fiber stop a bullet?

No, it has poor impact strength. Kevlar is used in bullet-proof jackets.

How does steel’s recyclability compare with carbon fiber?

Steel can be recycled but not carbon fiber. Recycling is very difficult because of composite nature and the degradation of materials upon recycling.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

German

German French

French Spanish

Spanish Russian

Russian Arabic

Arabic Norwegian

Norwegian Dutch

Dutch Finnish

Finnish Japanese

Japanese Chinese (Simplified)

Chinese (Simplified) Home

Home

Does Brass Rust? Corrosion, Oxidation, and Care

Does Brass Rust? Corrosion, Oxidation, and Care