18-8 Stainless Steel vs 303: The Comparison Guide

Dec 12,2023

Dec 12,2023

In the world of materials engineering, understanding the nuances between different types of stainless steel is crucial for a wide range of applications. In this comprehensive guide, we will delve into the characteristics, differences, and applications of two commonly used types of stainless steel: 18-8 and 303 stainless steel. Our aim is to provide you with in-depth knowledge and practical insights to make an informed decision for your specific needs.

Definition Of 303 Stainless Steel

303 stainless steel is a popular grade of stainless steel known for its excellent machinability and corrosion resistance. It belongs to the austenitic stainless steel family, which means it has a face-centered cubic crystal structure. This structure provides the steel with high ductility and toughness, making it suitable for various applications.

Is 303 Stainless Steel Austenitic?

Yes, 303 stainless steel is classified as an austenitic stainless steel. Austenitic stainless steels are non-magnetic and are characterized by their high corrosion resistance and strength at elevated temperatures. This makes 303 stainless steel ideal for applications in harsh environments where corrosion resistance is crucial.

303 Stainless Steel Properties

The addition of sulfur or selenium to 303 stainless steel improves its machinability. These elements act as lubricants during the machining process, reducing friction and heat buildup. As a result, 303 stainless steel can be easily machined into complex shapes with tight tolerances.

Find out why Tuofa leads in stainless steel machining.

What Is 18-8 Stainless Steel?

The first number 18 refers to the chromium content in the steel, and the second number 8 describes the nickel content in the steel. This composition provides a balance of corrosion resistance, strength, and workability. It's a popular choice for a variety of applications due to its versatility and reliability.

Is 18-8 Stainless Steel Austenitic?

Yes, 18-8 stainless steel falls under the austenitic category. Austenitic stainless steels are known for their non-magnetic properties and excellent formability, making them suitable for a wide range of applications, including those requiring welding and fabrication.

Difference Between 18-8 And 303 Stainless Steel

18-8 and 303 Stainless Steel Chemical Properties

The chemical composition of 18-8 stainless steel and 303 stainless steel differs slightly, resulting in variations in their properties. Here are some key differences:

- Alloying Elements: 18-8 stainless steel, also known as 304 stainless steel, contains 18% chromium and 8% nickel. On the other hand, 303 stainless steel contains additional sulfur or selenium, which improves its machinability.

- Chemical Composition Chart: The following table compares the chemical compositions of 18-8 and 303 stainless steel:

Differences in Mechanical Properties

The mechanical properties of 18-8 and 303 stainless steel also differ. Here are some key differences:

- Density: 18-8 stainless steel has a density of 7.93 g/cm³, while 303 stainless steel has a slightly higher density of 8.03 g/cm³.

- Hardness: 18-8 stainless steel typically has a hardness of 85 HRB (Rockwell B scale), while 303 stainless steel has a hardness of 95 HRB.

- Corrosion Resistance: Both 18-8 and 303 stainless steel offer excellent corrosion resistance. However, 18-8 stainless steel is more resistant to pitting and crevice corrosion in chloride environments.

- Yield Strength: 18-8 stainless steel has a higher yield strength of 205 MPa compared to 303 stainless steel, which has a yield strength of 190 MPa.

- Thermal Conductivity: 18-8 stainless steel has a thermal conductivity of 16.2 W/m·K, while 303 stainless steel has a slightly lower thermal conductivity of 14.4 W/m·K.

- Surface Finish: 18-8 stainless steel can achieve a variety of surface finishes, including a bright annealed or polished finish. 303 stainless steel is often supplied with a ground or rough turned finish.

Chinese Machining Services

Send drawings to info@tuofa-cncmachining.com

Faster and Cheaper

Density

The density of a material refers to its mass per unit volume. In the case of stainless steel, density is an important consideration for applications where weight is a factor. 18-8 stainless steel has a density of 7.93 g/cm³, which is slightly lower than the density of 303 stainless steel, which is 8.03 g/cm³.

Strength and Durability

a. 18-8 Stainless Steel

18-8 stainless steel, also known as 304 stainless steel, is known for its high tensile strength and resistance to stress corrosion cracking. It is a durable material that can withstand harsh environments, making it suitable for various applications.

b. 303 Stainless Steel

303 stainless steel has a lower strength compared to 18-8 stainless steel. While it offers good corrosion resistance, it may not be suitable for highly corrosive environments. However, its excellent machinability makes it a preferred choice for applications where intricate shapes and tight tolerances are required.

AISI 303 and 18/8 Material Comparison Chart

| Properties | 18-8 Stainless Steel | 303 Stainless Steel |

| Alloying Elements | 18% Chromium, 8% Nickel | Additional Sulfur or Selenium |

| Density (g/cm³) | 7.93 | 8.03 |

| Hardness (HRB) | 85 | 95 |

| Corrosion Resistance | Excellent | Excellent |

| Yield Strength (MPa) | 205 | 190 |

| Thermal Conductivity (W/m·K) | 16.2 | 14.4 |

| Surface Finish | Bright Annealed or Polished | Ground or Rough Turned |

Which Is Better 18-8 Or 303 Stainless Steel?

When determining which stainless steel grade is better for a specific application, several factors should be considered, including cost, availability, and required properties.

Cost and Availability

a. 18-8 Stainless Steel

18-8 stainless steel, being widely available, is relatively cost-effective. It is a popular choice for general-purpose applications due to its affordability. Its availability is also widespread, making it easy to source.

b. 303 Stainless Steel

303 stainless steel may be more expensive compared to 18-8 stainless steel due to its additional machinability properties. It may also have more limited availability compared to 18-8 stainless steel.

303 Vs 18-8 Stainless Steel: Manufacturing Process

Machinability

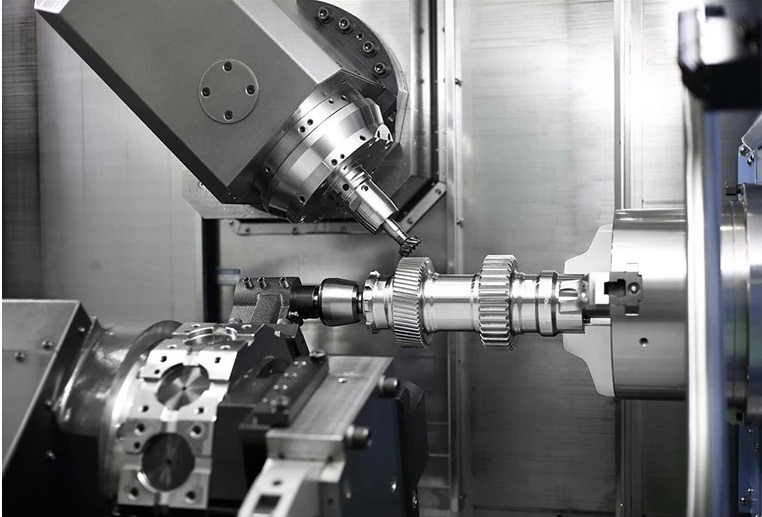

Machinability refers to the ease with which a material can be machined into a desired shape. 303 stainless steel is renowned for its excellent machinability. The addition of sulfur or selenium acts as a lubricant during the machining process, reducing friction and heat buildup. This allows for faster machining speeds and improved tool life.

Weldability

Both 18-8 and 303 stainless steel are weldable using appropriate welding techniques. However, it is important to note that 303 stainless steel may be more prone to hot cracking during welding due to its higher sulfur content. Proper welding procedures and precautions should be followed to ensure successful welds.

Try Tuofa Now!

Send drawings to info@tuofa-cncmachining.com

China Tuofa Engineer Support Team

Real human quotes are more accurate than software quotes

Applications Of 303 And 18-8 Stainless Steel

The applications of 303 and 18-8 stainless steel are diverse, given their unique properties and characteristics. Here's a look at how each type of stainless steel parts is commonly used:

What is 18-8 stainless steel used for?

18-8 stainless steel is suitable for applications requiring excellent corrosion resistance. It is commonly used in outdoor structures, marine equipment, and kitchen utensils. Its hygienic properties also make it a preferred choice in the food processing and pharmaceutical industries.

What is 303 stainless steel used for?

303 stainless steel is popular in machining applications. Its excellent machinability makes it ideal for precision parts, fittings, and shafts. It is also used in the automotive industry for components that require both corrosion resistance and machinability.

Conclusion

In conclusion, 18-8 stainless steel and 303 stainless steel have distinct properties that make them suitable for different applications. 18-8 stainless steel offers excellent corrosion resistance and is widely available at an affordable cost. On the other hand, 303 stainless steel is known for its exceptional machinability, making it a preferred choice for machining applications.

When selecting the appropriate stainless steel grade for your specific needs, consider factors such as corrosion resistance, machinability, cost, and availability. By understanding the differences between 18-8 and 303 stainless steel, you can make an informed decision for your application requirements.

The Best Chinese Stainless Steel Machining Service

The benefits of choosing China Tuofa for stainless steel machining services: I'm here to tell you about the wonders of choosing China Tuofa (www.tuofa-cncmachining.com) for your stainless steel machining needs. Imagine us working together, with me bringing the precision and expertise of Tuofa to your projects.

You see, when you team up with Tuofa, your projects get a whole new level of attention. China Tuofa engineers understand stainless steel like no other, tailoring we approach to fit exactly what you need. I can assure you, your challenging projects are in safe hands, and they'll be handled with the efficiency and effectiveness you desire.

Now, let's talk about value. I know how important it is for you to balance cost and quality. This is where I believe Tuofa really stands out. Tuofa stainless steel machining services are not just affordable; we come with a commitment to quality that's hard to find elsewhere.

So, how about we take this step together? With Tuofa, you're not just choosing a service provider; you're choosing a partner who's dedicated to bringing the best out of your projects.

FAQs

Does 303 stainless steel rust?

Yes, 303 stainless steel can rust, but it is more corrosion-resistant compared to many other steel grades. Stainless steels, including 303, contain chromium, which forms a thin passive layer of chromium oxide on the steel's surface, helping to prevent corrosion. However, this layer can be compromised under certain conditions, leading to rust.

303 stainless steel is specifically designed for ease of machining, but this comes at the cost of some decrease in corrosion resistance and toughness compared to other austenitic stainless steels like 304. The presence of sulfur, which is added to enhance machinability, can also reduce its corrosion resistance slightly.

It's important to note that while 303 stainless steel is more resistant to corrosion than ordinary carbon steels, it is not completely rust-proof. In environments with high salinity, exposure to certain chemicals, or under certain processing conditions, 303 stainless steel can corrode. Regular maintenance and proper cleaning can help to mitigate this risk.

Can 303 stainless steel be hardened?

303 stainless steel, known for its excellent machinability, is not well-suited for hardening through heat treatment. This is due to its austenitic structure and the presence of sulfur, which is added to improve machinability.

Austenitic stainless steels, like 303, contain a high proportion of chromium and nickel, resulting in a face-centered cubic crystal structure. This structure does not change or harden with heat treatment, unlike martensitic or ferritic stainless steels.

However, 303 stainless steel can be slightly hardened through cold working. This process involves deforming the steel at room temperature, which can increase its strength and hardness to some extent. But the extent of hardening achievable through cold working is much less than what can be achieved with heat-treatable stainless steels.

If hardness is a critical requirement for your application, other grades of stainless steel that respond well to heat treatment (like the 400 series martensitic stainless steels) might be more suitable.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

303 Stainless Steel: Properties, Applications, and Machinability

303 Stainless Steel: Properties, Applications, and Machinability