Understanding 3003 Aluminum: a Comprehensive Guide

Feb 11,2024

Feb 11,2024

Aluminum is a ductile material and lightweight. However, it is considered as a weak metal in pure form for structural and other applications. To make it applicable, it is melted and mixed with other alloying elements at elevated temperatures. The resultant aluminum has high corrosion resistance, strain-hardened and high hardness. 300 series aluminum is one of the resultant products which has different alloying elements and different properties.

This article will describe the 3000 aluminum properties along with its data sheet and applications and a brief comparison with other aluminum alloys and other metals. If you are dealing with aluminum alloys or have any project related to 3000 series aluminum, then this piece of writing will be helpful for you in deciding the best material for your project.

Introduction to 3003 Aluminum

AA3003 is a commonly used alloy from 3000 series aluminum because of its exceptional properties. It is composed of aluminum, added with Mn and Cu. These elements enhance its corrosion resistance and cold working properties when combined at higher temperatures. manages is almost 1.2% and copper has 0.12% in its composition.

3003 aluminum properties like machinability are considerable for many applications like for cookware and container. It is also used in making pressure vessels, for sheet metal fabrication, and for making hardware.

Historical background and development

The most abundant metal aluminum is not present on Earth as a free metal or native element. It is combined with other minerals such as bauxite and then isolated as pure aluminum. It was first discovered by Antoine Lavoisier in 1787. And in 1825, it was first extracted from bauxite by a Danish chemist Hans Christian.

Different terms for 3003 Aluminum

AA 3003 is also called diamond plate as treadplate. Because it has a shiny surface and has a diamond pattern. This has common applications as ornaments

.

Is 3003 Aluminum Magnetic?

AA3003 is a paramagnetic metal which implies it is weak magnet around the magnetic field but cannot attract other metal. It oxides rapidly and hard and brittle after plastic deformation.

Does 3003 Aluminum Rust?

AA3003 has high corrosion resistance and has long lifespan in the environment with high moisture and other aggressive medias.

Different forms of 3003 Aluminum

3003 aluminum properties are exceptional when it comes to machining and milling. AA3003 has different forms when it is tempered, strain-hardened, or has gone through cold working or plastic deformation. The cutting and extrusion of aluminum creates rods, hollow or solid shaped, rod and bars, pipes and tubes for many applications.

Chemical Composition

The datasheet of Chemical composition of AA3003 is shown in the table below:

|

Elements |

Percentage |

|

Aluminum |

97-98% |

|

Manganese |

1-1.5% |

|

Copper |

0.05-0.2% |

|

Silicon |

0.6% |

|

Iron |

0.7% |

|

Zinc |

0.10% |

|

Others |

0.05% |

Physical Properties

The datasheet of Physical properties of AA3003 are given below:

|

Physical properties at 20℃ |

Values |

|

Density |

2730kg/m3 |

|

Melting point |

650℃ |

|

Electrical conductivity |

50%IACS |

|

Electrical resistivity |

0.034m.ohm.m |

|

Thermal conductivity |

193 Wm/℃ |

|

Poisson’s ratio |

0.33 |

|

Tension |

68.9GPa |

|

shear |

25GPa |

|

Mean coefficient expansion |

21.5x10-6℃ |

|

Specific heat |

0.123 Btu/lb ᵒF |

Mechanical Properties

The datasheet of Mechanical properties of aa3003 and its tempers like O, H12, H14,H16, and H18 are given below:

|

Alloy &temper |

UTS (ksi) |

Yield set .2% |

1/16” thickness |

½” dia |

Tensile strength MPa |

Elongation %min |

Brinel hardness |

|

AA3003-0 |

14-19 |

6 |

30% |

40 |

95-130 |

14-21 |

28 |

|

3003-H12 |

17-23 |

18 |

10% |

20 |

115-160 |

3-8 |

35 |

|

3003-H14 |

20-26 |

21 |

8% |

16 |

135-180 |

1-8 |

40 |

|

3003-H16 |

24-30 |

25 |

5% |

14 |

165-205 |

1-4 |

47 |

|

3003-H18 |

27 |

27 |

4% |

10 |

185 |

1-4 |

55 |

The datasheet of Key to Tempers are as:

|

Tempers |

Condition |

Tempers (second digit x) |

Condition |

|

|

0 |

Annealed (soft) |

8 |

Full hard |

|

|

H1x |

Strain-hardened only |

6 |

3/4hard |

|

|

H3x |

Strain hardened and stabilized |

4 |

1/2hard |

|

|

- |

- |

2 |

1/2hard |

|

Chinese Machining Services

Precision Engineering for Innovators

Send drawings to info@tuofa-cncmachining.com

Faster and Cheaper

Manufacturing Process

Common manufacturing process of aluminum 3003 are hot working and cold working which further include rolling, extrusion, forging, upsetting, liquid or semi-liquid forging, continuous casting and rolling, and continuous casting and continuous extrusion.

Heat treatment

Heat treatment of aluminum 3003 alloy is carried out at 260-510℃by hot working. Annealing is carried out 413℃. As pure alloy it cannot be cast and has no response by heat treatment.

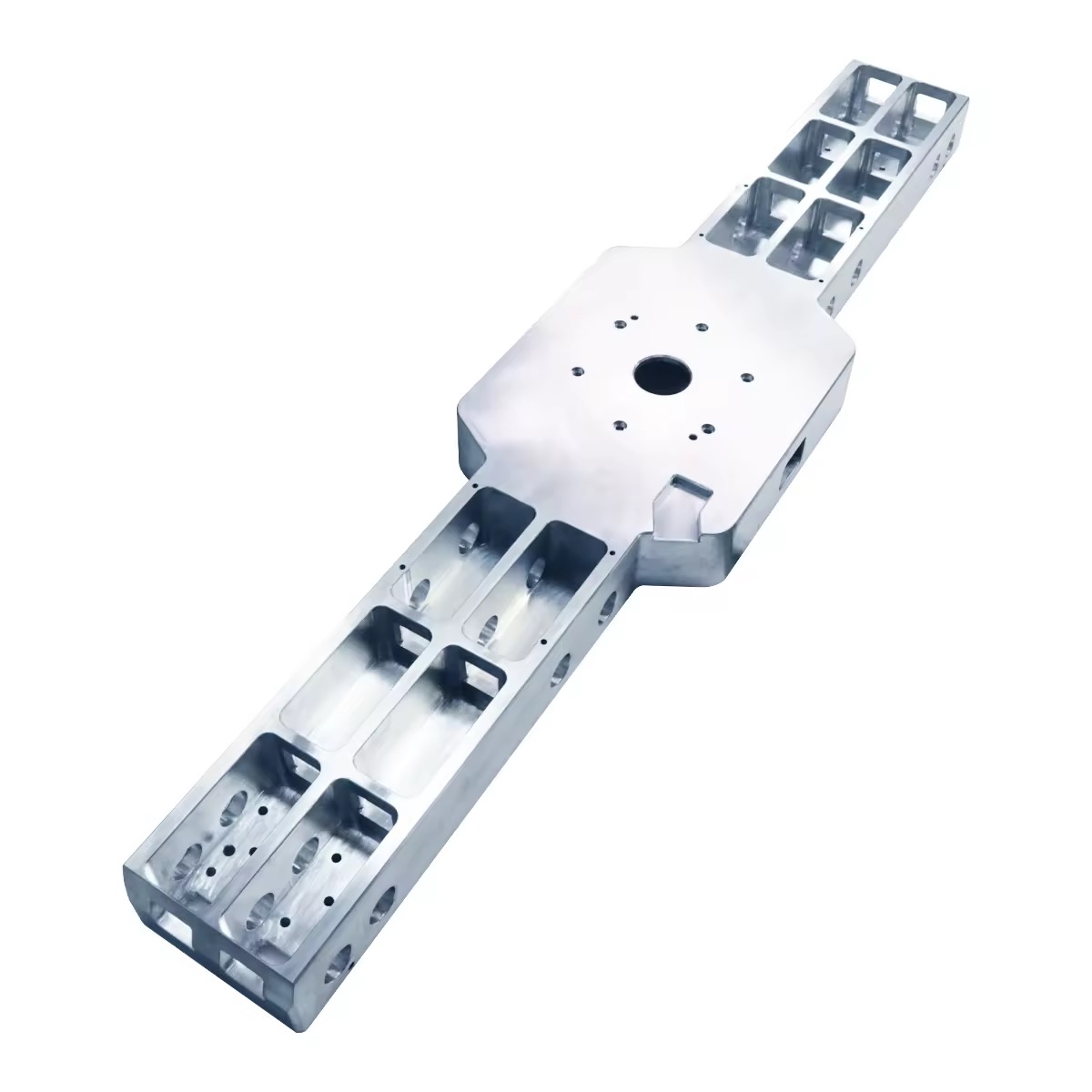

CNC Machining

Aluminum is the most used cutting alloy for CNC routers. AA3003 can easily CNC machined and can be cut, drill and mold into any desired shape. 3003 aluminum is considered as the excellent alloy in machinable metals.

Weldability

3003 aluminum is the best choice when requires medium hardness and good weldability in material. AA3003 can be welded by using standards of Gas tungsten arc welding, gas metal arc welding and shieled metal arc welding.

Surface Treatment

Normally the surface treatments given to AA3003 are anodic oxide coatings, mechanical surface treatments, Alodine coating, anodizing, bright anodic coatings, enamel coatings, coloration and electroplating.

What is 3003 aluminums used for?

3003 aluminum properties are exceptional and have many applications.

Utensils and cookware

Food containers and cooking utensils are normally made of aluminum 3003 because it has good heat resistance, corrosion resistance and does not melt even at high temperatures. oxidation resistance of 3003aluminum is high and does not corrode when expose to heat for a long time.

Decorations

Aa3003 is soft and ductile material and can attain any shape for intricate and ornate designs. It is good for warping and bending.

Construction

Aa3003 is famous as a construction material because it is lightweight and has a long lifespan. It is also ductile and can gain any shape for parts like hinges, locks, sheets, garage doors. It is easy to install, and energy efficient garage doors are highly demanded.

Gas pipelines

Aa3003 has many applications in gas lines due to high strength. It is also a cost-effective material and has high corrosion resistance and durability.

Ductwork

It is one of the common applications of 3003 due to being lightweight, easy in installation, high strength and can endure high temperature without failing.

Heating/cooling systems

Aa3003 is best suited for heating and cooling applications. Radiators of aluminum are lightweight and have high thermal conductivity. Other than that, AC evaporators, car radiators and heat exchanger are made of AA3003.

Roofing

It can cover flat and pitched roofs and its sheets are flexible. It can withstand heavy snowfall and remain corrosion resistant.

Standards and Specifications

The ASTM Product specifications of aluminum 3003 are as:

|

Specifications |

Titles |

|

B209 |

Aluminum and aluminum alloy sheet and plate |

|

B210 |

Aluminum and aluminum alloy drawn seamless tubes |

|

B483 |

Aluminum and aluminum alloy drawn tubes for general purpose applications |

Pros and cons of 3003 Aluminum

The pros and cons of 3003 Aluminum are as:

Advantages

· Durable

Alloy 3003 is highly durable due to Al2O3 film over the surface. It provides weather protection, oxidation resistance and temperature resistance to the alloy.

· Lightweight

Aluminium has low density of 2730kg/m3 which makes it a lightweight material. This has many applications as construction material and also in automobile, aerospace, space and marine industries.

· Strength

Aa3003 contains Mg and Mn which increases its strength at high temperatures and in aggressive environments. High stiffness and strength make it suitable for many applications.

· Formability

Aa3003 has good formability, welding properties and shows good plasticity after plastic deformation. The strength and ductility perform better at lower temperatures. The working performance is also better at low temperature.

· Corrosion resistance

Presence of protective layer over the surface of aluminium 3003 protect it from corrosion and oxidation. It has good high temperature resistance. The alloy can survive harsh environments with salt and toxic chemicals. It is a good roofing material because it can bear heavy snowfall and still weather protection.

· Appealing appearance

Aluminium 3003 are dived into non-painted and painted plates. The painted or treated aluminium like anodized, or Alodine coated aluminium has good surface finish and looks good when used for domestic applications.

· Cost-effective

It is cost-effective material which provides, corrosion resistance, oxidation resistance, good weldability, formability, ductility, easy to bend or reshaped, easy to install and can be surface treated easily.

Limitations

300 Aluminum properties are exceptional but still have some limitations. It is difficult to harden with heat treatment. Hardening can be done by cold working and through ‘Tempers like H12 quarter hard and h14 half-hard and soft annealed by ‘O’ temper condition but this makes the process long and costly.

Other than that, the fracture toughness of aluminum 3003 is lower than steels which make it limited for many applications. It also limits its applications at high temperatures.

Try Tuofa Now!

Custom solutions for complex designs: send drawings to info@tuofa-cncmachining.com

Real human quotes are more accurate than software quotes

Comparison with other Materials

Comparison of aluminum 3003 with other materials describes the major differences that can affect the performance and applications of materials. Aluminum alloy 3003 H14 is known for its high welding properties and workability. But aluminum alloy 3105 H14 has better strength and finishing properties. While the alloy 3004 H14 has high formability which is good in making complex shapes and intricate designs.

What is equivalent to 3003 Aluminum?

3003 aluminum h14 is one of the famous alloys and its equivalent alloys are 3105-H14 and 3004-H14. They both have equivalent mechanical properties and also used in the place of 3003 aluminum alloy H14. These alloys also have properties like corrosion resistance, stiffness, and formability same as 3003-H14 which make them suitable for many applications like for manufacturing, transportation, packaging and construction.

When to use 3003 Aluminum Parts?

3003 aluminum alloy has many applications due to outstanding properties. It is mostly used for heating and cooling applications. It is also a thermally conducting material and serves as radiators and heat exchangers. It also has exceptional corrosion resistance and moisture resistance, so it is also a good roofing material.

Cost-Benefit Analysis

3003 series aluminum are relatively cost-effective materials and has low price as compared to other materials available in market. For example, aluminum alloy 6001 is a very in demand alloy and has many applications but it has higher cost than 3000 series aluminum which makes it some of the applications limited.

Advanced Fabrication Techniques

The common fabrication techniques of aluminum are casting, forging, rolling and extrusion. But high-quality properties in 3003 series aluminum are possible to obtain if these are applied with different techniques. Therefore, these techniques with modifications are commonly used for the fabrication of aluminum.

Conclusion

Aluminum alloy 3003 has Mn and Cu in its chemical composition. This increases its strength and corrosion resistance. It is a lightweight material which increases its demands in construction. It is nonmagnetic in nature. It also has good thermal conductivity and electrical conduction properties. Common applications of aluminum 3003 are storage tanks, piping, pressure vessels, heating and cooling systems and roofing. It is not a heat treatable alloy, but the workability and formability are good in aluminum 3003. AA3003 in tempered conditions or strain-hardened alloy like O, H12, H14, H16 and H18 are widely used for different applications.

TUOFA CNC machining offers the best services in aluminum sheet metal fabrication. Tuofa offers services like lean manufacturing, rapid prototyping, and custom manufacturing services of aluminum parts. TUOFA has years of experience with high quality equipment and well-trained staff that can guide you in selecting the best material and technique for your project. Feel free to contact at https://www.tuofa-cncmachining.com/

FAQ

Is 3003 aluminum food safe?

3003 aluminum alloy has moisture resistance. Its higher oxidation resistance properties help in extending the life of a variety of things. 3003 aluminum foil is non-toxic, safe, and high-quality food grade material. This implies it has no side effects.

3003 aluminum vs 5052

3003 aluminum alloy is ductile and has good corrosion resistance. the workability, drawing ability, weldability, and strength are also good in 3003. But in comparison with 5052 aluminum alloy, the properties of aluminum 3003 are low. 5052 aluminum alloy has high strength and corrosion resistance. it also has better formability and weldability

3003 vs 3004 aluminum

3003 aluminum and 3004 aluminum alloys have the same composition. But 3004 aluminum alloy has better strength because of having extra 1% magnesium.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Understanding 5052 Aluminum: A Comprehensive Guide

Understanding 5052 Aluminum: A Comprehensive Guide