416 Stainless Steel Material Properties | 400 Series Stainless

Feb 01,2024

Feb 01,2024

The 400 series stainless steel data sheet includes 416 stainless steels which is categorized as martensitic stainless steels. It has improved physical and mechanical properties due to different heat treatments like annealing, tempering and quenching. These heat treatments improve the stainless-steel wear resistance and have high strength but reduced impact resistance. These 400 series of steels have more manganese and chromium content as compared to 300 series which contains 11% chromium and 1% manganese. These elements cause improvement in the mechanical properties like stainless steel wear resistance and strength. Valves, shafts and gear are all simple applications of 416 stainless steels. In these applications, wear resistance and high strength with corrosion resistance are the main required properties.

Material 416 Stainless Steel

There are different stainless steel data steels available as given below;

- UNS S41600: This designated system of numbering is for the 416 stainless steels. It is used to identify alloys and metal and is widely accepted numbering system.

- AISI 416: The American Iron and Steel Institute (AISI) provides each steel with 4-digit numbers. This is designed to specify the stainless-steel types.

- Type 416: These are very common but generic names; 416 stainless steel is one of them. 430, 304 and 316 are also the example of them.

- X12CrS13: This is the EN (European Norm) standard or European designation as 12 refers to chromium percentage, X refers to highly alloying steels and CrS refers as sulfur content for machinability.

- 416Se: These Se indicates as the presence of Selenium. So, this particular system addresses Se in 416 stainless steels.

- F6NM: Some specification and standard also use designation for the 416 stainless steel.

- AMS 5610: The AMS (Aerospace Material Specification) system where 5610 is used for the 416 stainless steels.

Is 416 Stainless Steel Austenitic?

416 stainless steel is magnetic martensitic stainless steel but not austenitic stainless steel. 416 stainless steels in 400 series are well known for high strength, wear resistance and corrosion resistance at quenched and tempered form.

Is 416 Stainless Steel Magnetic?

Yes, 416 is the martensitic stainless-steel alloy which is generally magnetic.

Does 416 stainless steel rust?

Yes, 416 stainless steels in 400 series are moderately corrosion resistive. It does not have high corrosion resistance as compared to ferritic and austenitic stainless steel. It retains its properties in humid atmosphere but in harsh environment containing chlorides and sulfur.

Different Forms of 416 Stainless Steel

416 stainless steel is a martensitic, free-machining grade of stainless steel with added sulfur or selenium. The composition makes it one of the first stainless steels specifically adapted for machining. China Tuofa has its own unique innovative methods for stainless steel machining. There are different forms of 416 stainless steel, primarily distinguished by their processing methods and resulting material properties. Here are the common forms:

Forging 416 Stainless Steel

Forging of 416 stainless steel is carried out to obtain homogenous structure to enhance the mechanical properties like yield strength, ultimate tensile strength and toughness.

Forging of 416 Stainless Steel

YouTube video of forging of the knife.

416 Stainless Steel Bar Stock

Straight bars are formed from 416 stainless steels with specific cross section which are used in machining application for the production of different components like valves and fasteners.

416 Stainless Steel Bar Stock

416 Stainless Steel Plate

416 stainless steels having the rectangular and flat metal plates which are used in the fabrication of parts. It covers the applications where a large surface area is required like structural components and making machine parts.

416 Stainless Steel Plate

416 Stainless Steel Sheet

416 stainless steel containing chromium content in its composition which is also available in thinner, flat sheet forms. It is used in the applications such as decorative trims and electronics components which required small surface area.

416 Stainless Steel Sheet

416 Stainless Steel Rod

AISI 416 also available in the form of the log circular metallic rod with specific circular cross section. It is used in the application where the strength and stiffness are required i.e., fabrication of axles and shafts.

416 Stainless Steel Rod

416 Stainless Steel Resistance

From 400 series, 416 stainless steel is well used in different applications due to its good physical and mechanical properties. Wide range of mechanical properties can be achieved due to different heat treatments like annealing, normalizing, quenching and tempering.

Corrosion Resistance

Wear resistance and strength of 416 stainless steel is high in hardened and tempered conditions. 416 stainless steel shows high resistance in the humid environment and can retain its properties without corroding. On the other hand, sulfuric humid environment gives tough time to 416 stainless steel which causes the corrosion. Eventually, reduction in its physical and mechanical properties happen.

Heat Resistance

416 stainless steels wear resistance as well as resistance to scaling in service life time, can be maintained up to 1400°F (760°C) and 1247°F (675°C). It is also recommended to use it above the tempered temperature of 416 stainless steel if you want longer life for better corrosion resistance.

Heat Treating 416 Stainless Steels

416 stainless steels have tempering temperature of range 750-1110°F (400-600°C) which result in high wear resistance and less impact strength. Heat treatment can be performed at 1400°F to enhance the mechanical properties of the 416 stainless steels.

Chinese Machining Services

Precision Engineering for Innovators

Send drawings to info@tuofa-cncmachining.com

Faster and Cheaper

416 SS Composition

416 stainless steel data sheets of Composition

|

Element |

Composition (wt. %) |

|

Carbon |

0.15 max |

|

Manganese |

1.25 max |

|

Silicon |

1.00 max |

|

Chromium |

12.00-14.00 |

|

Phosphorus |

0.06 max |

|

Sulfur |

0.15-0.35 |

In 400 stainless steel series, high chromium content is present in the composition of 416 stainless steel. High chromium content makes it highly resistant to rust. Additionally, its malleability is enhanced by the presence of sulfur. The martensitic stainless-steel structure makes it durable and sturdy, but it may also tend to be brittle and less pliable as compared to other steel types. Wear resistance and wear impact are further improved due to the presence of carbon content in the composition of these 400 series. The 400 stainless steels can be tuned for changing and improving its properties.

Physical Properties of SS 416

416 stainless steel data sheets of Physical properties.

|

Property |

Value |

|

Density |

7,600(kg/m^3) |

|

Elastic Modulus |

200(GPa) |

|

Coefficient of Thermal Expansion |

10.8 x 10^-6/°C |

|

Thermal Conductivity |

24-27(W/m·K) |

|

Specific Heat |

460(J/kg·K) |

|

Electrical Resistivity |

0.55-0.6 x 10^-6(Ω·m) |

|

Specific Gravity |

7.6 |

SS 416 Mechanical Properties

416 stainless steel data sheets of mechanical properties

|

Tempering Temperature |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Hardness Rockwell |

Elongation (%) |

Hardness (Hv) |

|

150°C |

690 |

415 |

28 |

15 |

275 |

|

200°C |

655 |

380 |

27 |

16 |

255 |

|

250°C |

620 |

345 |

25 |

17 |

235 |

|

300°C |

585 |

310 |

23 |

18 |

215 |

|

350°C |

550 |

275 |

21 |

19 |

195 |

|

400°C |

515 |

240 |

19 |

20 |

175 |

|

450°C |

480 |

205 |

17 |

21 |

155 |

|

500°C |

445 |

170 |

15 |

22 |

135 |

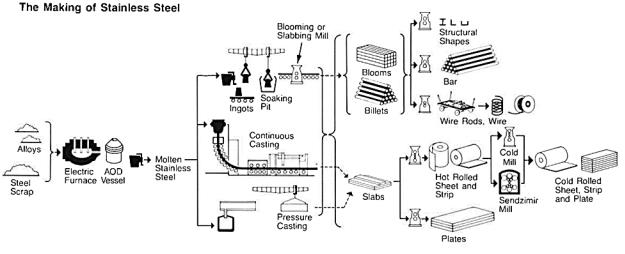

Manufacturing Process of 416 Stainless Steel

The development of 416 stainless steel involves electric furnace process. It may include the following process from manufacturing to heat treatments till machining.

Raw Material Extraction

The extraction of stainless steel is done in desired percentage of the alloying elements. The raw materials may contain a lot of other metal like iron ore, chromium nickel and other alloying elements.

Melting and Refining

The raw material is melted in a basic oxygen furnace or the electric arc furnace. The composition of the alloying element like chromium, sulfur and carbon should be adjusted by refining the molten metal.

Casting

when composition is adjusted then the molten 416 stainless steel is converted into semi-finished form like slabs, blooms and billets. These are further processed by the hot rolling.

Hot Rolling

Hot roller causes the heating and processing of the slabs, blooms and billets in to a thinner form such as bars and coils.

Annealing

The annealing of the 416 materials carried out so that the fabrication stresses can be relieved and to enhance the machinability. Annealing is the type of post heat treatment in which the metal is taken to certain temperature and the slowly cooled down. Slow cooling avoids internal stresses.

Cold Working

It is an optional process but is done in all type of stainless steels including 400 series. It is also known as cold rolling and cold drawing which is carried out to improve mechanical properties.

Cutting and Machining

It involves the machining and cutting of the 416 stainless steel to convert it into the desired final product with proper dimension and surface finish. It includes grinding, milling and turning and other.

Heat Treatment

The mechanical properties can be enhanced by changing the microstructure of the 416 stainless steels. The desired combination of mechanical properties like hardness, ductility, toughness and strength can be obtained. Typical heat treatment for the 416 stainless steel is the quenching to make martensite followed by tempering.

Testing and Quality Control:

ASTM A582, ASTM A484, and AMS 5610 standards are used for quality Esurance.

Finishing

The polishing and pickling type of finishing process are used to improve surface finish of the 400 series of stainless steel and so is the case with 416stainless steel.

Making of the 400 series of stainless steel including 416 stainless steel.

Try Tuofa Now!

Custom solutions for complex designs: send drawings to info@tuofa-cncmachining.com

Real human quotes are more accurate than software quotes

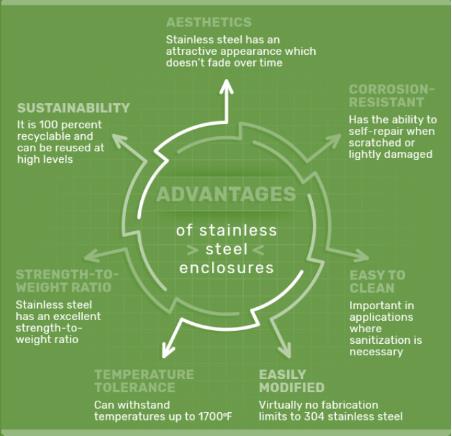

Pros and Cons of AISI 416

Advantages

AISI 416 stainless steel has advantage in high machinability making it ideal for the manufacturing processes that contain precise and efficient demand operations. The addition of the sulfur helps in chip breaking during machining which cause reduced production coat and improved tool life.IT help in the enhance production and contribution with widespread use in the industries that priorities the cost effective and streamed lined manufacturing processes.

Limitations

416 stainless steels have limited corrosion resistance in certain conditions which makes its application reserved. Caution needs to be taken where corrosion resistance is critical. It required a lot of post weld heat treatments and pre-heating to resist the risk of cracking and preserving the material mechanical properties. It is important for the engineers to keep these limitations in mind while choosing SS416 for specific applications.

What is 416 Stainless Steel Used For

Following are the uses of the 416 stainless steels.

- Machined Components.

- Shafts and Pump Parts.

- Valve Components.

- Firearms and Weaponry.

- Automotive Applications.

- Medical Instruments.

- Food Processing Equipment.

- Machining Fixtures and Tooling.

- Aerospace Applications.

- Textile Industry.

Conclusion

It is concluded that the martensitic 416 stainless-steel is the magnetic steel used in the application where strength and wear resistance is the most desired application. It also possesses non- galling and good machining properties due to high sulfur content. It does require heat treatments like annealing, quenching and tempering for fabrication. ASTM A582, ASTM A484, and AMS 5610 standards are used for quality Esurance of 416 stainless steels. It has applications in diverse industries like medical instrument, automotive, firearms and weapon.

How China Tuofa Can Help You Custom 416 Stainless Steel Parts

Experience the excellence of Tuofa in CNC machining for your 416 stainless steel parts. Trust our expertise for quality and precision. Don't wait - send your designs to Tuofa today and join the many satisfied customers benefiting from our exceptional service and technical prowess. Act now, share your drawings, and let Tuofa bring your vision to life with unmatched professionalism. send an email to info@tuofa-cncmachining.com to start your project.

FAQ

Is 416 stainless steel good for knives?

AISI 416 stainless steel is not recommended for knife production due to its limited edge retention, hardness, and toughness properties...

416 vs 416r stainless steel

AISI 416 and 416R both are types of martensitic steels well known for machinability but both have different content of sulfur in them...

4140 chrome moly steel vs 416 stainless

4140 chrome moly steel and 416 stainless are different types of stainless steel in composition as well as in properties...

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Understanding 3003 Aluminum: a Comprehensive Guide

Understanding 3003 Aluminum: a Comprehensive Guide