How Much Does Prototype CNC Machining Cost?

Oct 08,2024

Oct 08,2024

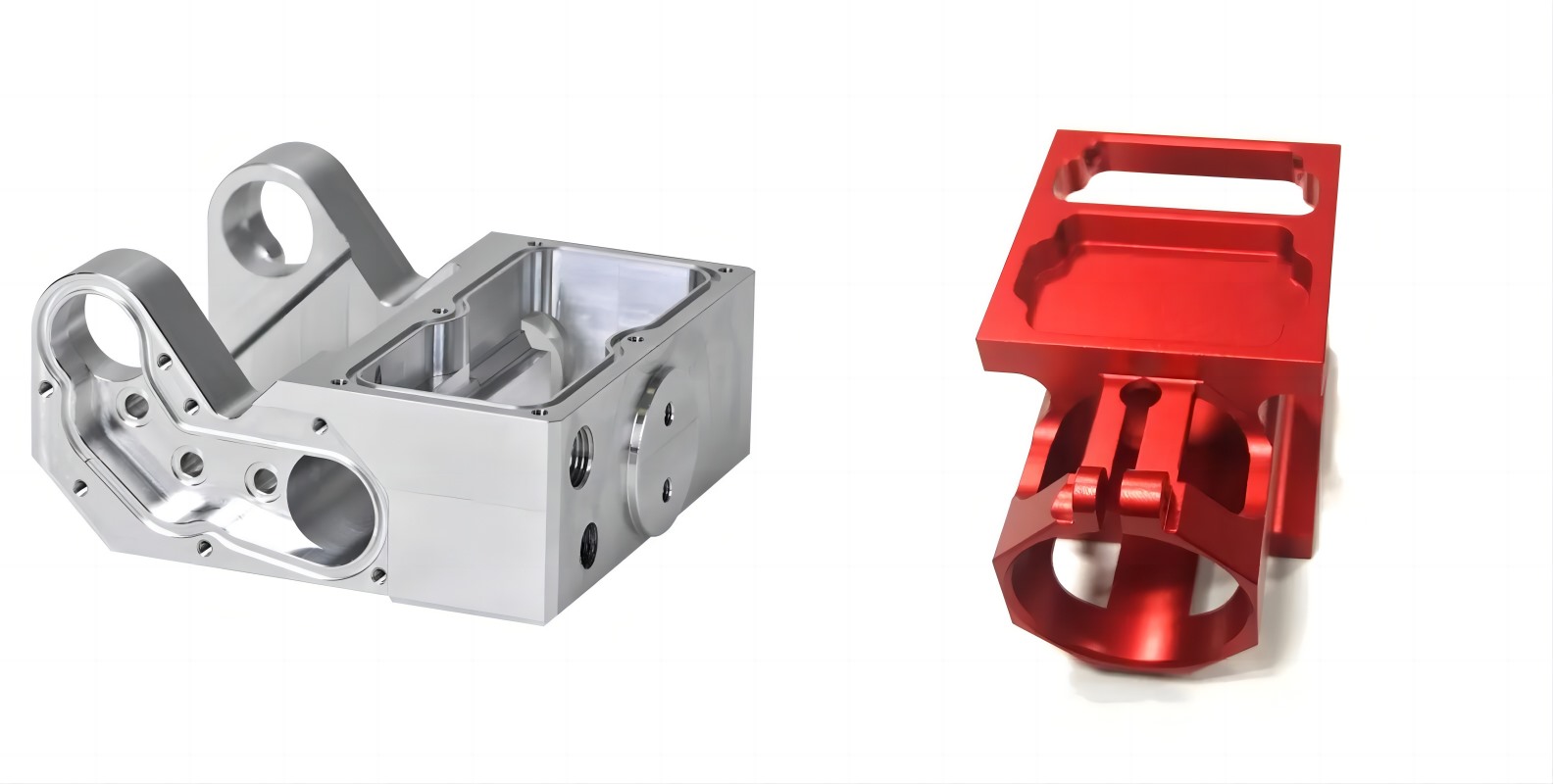

If you are considering prototype CNC machining part for your project, there are few things need to be understood related to the costs. These are effective financial planning, informed decision-making during product development and resource allocation. An average prototype machining cost is ranged between $50 to $500. A large cross section can cost up to $1000. This depends on the cost of raw materials, machining, post processing and overhead cost. This article will provide valuable tips to minimize expenses and guide the manufacturer to correctly estimate the cost of prototype CNC machining parts.

What is Prototype Machining?

It is a process of creating product testing parts rapidly using CNC machines. This is a low-volume production. It has the purpose of providing visual and functional testing prototypes of the final product. This helps in determining the physical turn out of a digital design.

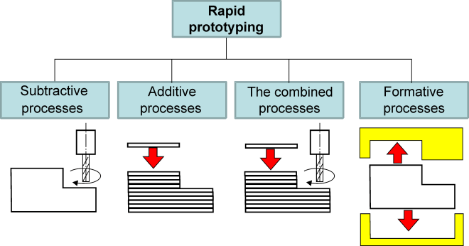

Rapid Prototype Machining Definition

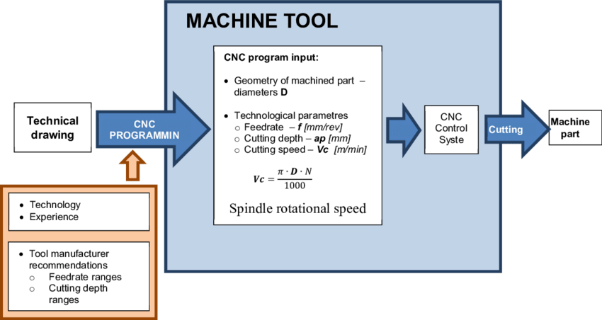

Rapid prototyping is a quick process of a part or assembly production with high-tolerance machining by using computer-aided designs (CAD). The rapid prototype development is completed by additive manufacturing or 3D-pritnign method. With this method, designers can pursue protype development directly in the CAD software from digital models faster. This helps in executing quick and frequent design modification based on real world testing after functional testing prototypes.

Tolerances in Prototype CNC Machining

Machining tolerance is the total variation amount to a specific dimension from a reference value. This variation is acceptable and as expressed in upper and lower limit. A standard prototype CNC machining tolerance is 0.13mm or +/-0.005in. This represents that any feature of a part like length, width, diameter, thickness must not be exceeded from this number in functional testing prototypes.

Pros and Cons of CNC Prototype Services

The pros and cons of CNC prototype development are as:

Advantages

- Digital process

Being a digital element eliminates all kinds of risks of human error. This process sends instruction digitally with CAD software to the cutting tools for porotype development. The digital deigns have easy modifications and designers have to modification to the file in product testing parts.

- Product quality and consistency

Protype development through machining has low fidelity to designs due to high-tolerance machining. The product quality does not change with repeatability. This feature is important when iterative porotype development is concerned and when the final part must be made with same machine.

- Wide choice for material selection

protype machining has a variety of material option unlike 3D printing. These options include stronger, durable and reliable materials,

- Proximity to the final part

Prototype machines can create parts with highly resemblance to final parts. This is almost impossible with other machining options. The same material used in prototype machining can make same final product with same features and properties as functional testing prototypes.

Disadvantages

There are few limitations too with prototype machining.

Costly

Prototype machining is an expensive technique. Workshops require heavy amount of machinery which needs high investment. If cost-effective is a big concern, then most manufactures do not consider this an option.

Geometrical Limitations

Elaborated structures are not accommodated in prototype machining. However, 4-axis and 5-axis offer some CNC machines offers flexibility, but still not enough.

Material wastage

prototype machining is a subtractive method. Extra material is cut away form part and ends p like chips or waste material. This increases the material costs.

Factors that Impact CNC Machining Costs

There are a few factors that influence CNC machining costs.

Design complexity

Part design can affect the cost greatly. The simple designs are cheaper to build than the complex designs because simple design are faster to machine. If a design has undercut, hole sizes and high detailing increase the machining time

Tolerances

CNC machining is one of the high-tolerance machining process today. But it does not necessarily mean that the assembly always require highest degree of accuracy. Tighter tolerance can result in cost increment of CNC machining process. This also increase the production times. CNC machining cost can increase by double between +/-0.03 and +/-0.005 tolerance where one is rough and the other one is standard tolerance, respectively.

Material selection

The choice of material can affect the overall cost of CNC machining. Raw material cost cannot be changed but lower production cost is always preferred. For example, plastic is cheaper than metal. Therefore, plastic is more common option in low-volume production. ABS, POM, PC, PA all are common material. Among metal, aluminium alloy is cost-effective material.

Finishing choice

Post-processing procedures can also increase overall cost of project. But there are options that require no post-processing procedures. Finishing procedures are normally carried out for to enhance different features of product testing parts. These are functional properties like durability, smoothness, or aesthetic qualities.

Steps to Develop a Prototype

There are a few steps involved in prototype development.

Product vision

The most important part of any project is the purpose of this project. Without knowing it, it is impossible to know what your users desire, the risk involves in overall project, and the gap that product filled between the user and their needs.

Creatin model by CAD

CAD software is used to create 3-D replica of the design for product testing parts.

Physical Prototype development

The main purpose of the prototype development is to get insights into what work for users. There are few types of protypes for selection:

- Low-fidelity - Basic, or mock-ups.

- High-fidelity - Highly functional testing porotype.

- Live data - in the form of code and uses live data.

- Feasibility – to test one specific feature of a product.

The porotypes can be built by 3Dpritnig which is a cost-effective option. Other option is CNC machining whish creates s high functional testing protypes.

Prototype testing and results evaluation

The prototype testing can provide the insight of user response and helps in gathering feedback.

Production-ready protype

once the design is tested and verified; it is ready to produce in bulk.

How Much Does Prototype Machining Cost?

The prototype machining cost has various factors to consider. These are as:

Prototype Cost Estimation

- Material and machinery Costs

Material cost involves bill of quantities that include the supplies, and the amount of raw material needed. The number of machines and tools to be use will be included.

- Labor Valuation

Labor cost is different for each product testing part. Some requires high-skilled labour, but some can be done with medium-skilled labour. Sometimes training is also required before staring the project, this would be included in the labour cost. This includes the work to produce parts, assembling and working of the parts.

Risks Estimation

All the risk related with the porotype development must be addressed before the project beginning. Some risk requires modification in model that would be done before the project implantation. And there are few risks that requires necessary precautions like kits, masks etc which will be included in cost. Therefore, risk estimation is also important.

- Profit

Profit must be included in the prototype development cost. This will be used in sending bill to clients and customers.

Lead Times in Prototype CNC Machining

Lead time is normally from a few days to serval week depending on the parts geometry and complexity. Lead time is also affected by the CNC machining service that has been selected.

Tips to reduce the cost of rapid prototyping

There are few tips to reduce the cost of rapid prototyping.

- Design optimization by choosing simple and easy designs of prototype.

- Order small quality of batch to test and validate the design before large production

- Use compatible material that is cost-effective and readily available to avoid shipping cost

- Save on post processing procedure by choosing right material

Prototype Cost vs Production Cost

Prototype development has a smaller total cost. It is always ordered in small batches and has a low-volume production. But this involves high-tolerance machining, which can be costly sometime if the design is complex. Production cost is cost effective when high-quality products are required for mass markets.

Best Online CNC Service at Tuofa China

TUOFA offers the best CNC services in the market, which has greater accuracy, more precise control and greater efficiency for low-volume production. The prototypes parts are created and inspected thoroughly at every stage to minimize the production delays caused by malfunctions.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

TOP 10 CNC Machined Parts Suppliers in the World

TOP 10 CNC Machined Parts Suppliers in the World