18/10 vs 304 Stainless Steel: Which Triumphs?

Jun 11,2024

Jun 11,2024

Stainless steel is well known for its outstanding properties and numerous applications, especially in the realm of materials science. It comprises of various grades which are categorized based on their distinct properties and usage. In this article, a comprehensive comparison between 18/10 and 304 stainless steel that are famous for properties like corrosion and heat resistant along with other characteristics. So, regardless of your educational background, this article will provide you with a base to select the respective material for your application.

YouTube Link:

18/10 Stainless Steel

18/10 SS is considered as one of the high-quality steels with chromium and nickel as its major alloying elements. It comprises of properties like good heat resistance, corrosion resistance with ease of fabrication. Moreover, it is nontoxic in nature and does not trickle into food. Major applications include cookware, cutlery etc.

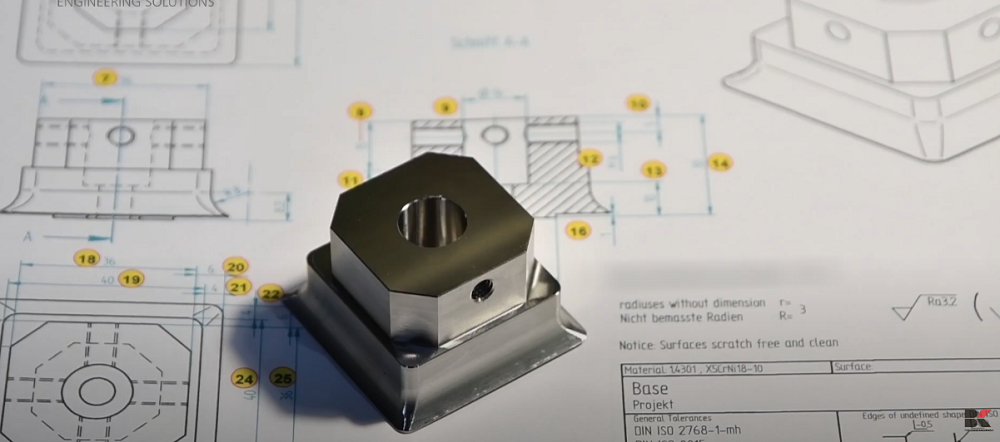

Figure 1: 18/10 SS grade

Is 18/10 Stainless Steel Rust Proof?

The presence of chromium and nickel in its composition makes it resistant to rust as well as corrosion. A passive layer is formed on the surface of 18/10 SS due to chromium which helps it against rusting. In addition, nickel contributes to adding lustrous finish and provide resistance against corrosion. However, it may alter its behavior in aggressive conditions.

SS 304 Stainless Steel

SS 304 constitutes of chromium, nickel, and iron along with other alloying elements. This austenitic SS is usually non-magnetic in nature along with high corrosion resistance. Furthermore, it can withstand elevated temperatures without altering its properties. Additionally, it offers ease of fabrication and hygienic properties which allows it to be utilized in commercial as well as industrial sectors. Major applications include kitchen appliances, automotive etc.

Figure 2, 304 grade stainless steel.

YouTube link:

https://www.youtube.com/watch?v=7T4GvUNUWxQ&pp=ygUMMzA0IGdhcmRlIHNz

Are 304 and 18/8 the Same?

As far as chemical composition is concerned, both grades comprise of somehow similar composition but there are other factors in terms of properties and cost which makes a little difference. 18/8 is best for mildly corrosive environment while 304 SS is exceptional when aggressive conditions must be tailored. Moreover, 18/4 is less expensive than 304. Apart from this, 18/8 is mostly suitable for general applications i.e., cookware, flatware etc. while 304 grade is ideal for highly corrosive environments.

Advantages and Disadvantages 18-10 and 304

Below are some of the pros and cons of both grades:

18/10 Stainless Steel

| Advantages |

Disadvantages |

| High corrosion resistant | Non magnetic |

| Aesthetic appeal | Weight |

| Durability | Susceptible to chlorides |

| High heat resistant | |

| Non reactive surface |

304 Stainless Steel

| Advantages | Disadvantages |

| Versatility | Easy to scratch |

| Good corrosion resistant | Poor high temperature resistant |

| Fabrication ease | |

| Non magnetic | |

| Recyclable |

Applications and Parts

Both grades have numerous applications. Some of them are mentioned below:

18/10 SS:

- Jewelry

- Pharmaceutical

- Decorative Elements

- High-End Appliances

- Kitchenware

Figure 3: 18/10 SS Applications

304 SS:

- Marine

- Architectural

- Healthcare and Laboratory

- Automotive

- Food and Beverage

Figure 4: 304 SS Applications

Food grade stainless steel

This grade of stainless steel is designed to meet the performance criteria particularly for food related applications. It can maintain necessary food safety standards such as hygiene and resistance to corrosion to avoid contaminants and other harmful chemicals to mix up with food. Common grades include 304, 316, 18/10 etc.

18-10 and 304 Stainless Steel: Chemical Composition

Below is the chemical composition of both grades of stainless steel:

Table 1: Chemical composition

|

Elements |

18/10 SS |

304 SS |

|

Cr |

18 |

18-20 |

|

Ni |

10 |

8-10.5 |

|

Fe |

Balanced |

Balanced |

|

C |

0.08 |

≤0.08 |

|

Mn |

2 |

2 |

|

Si |

1 |

1 |

|

P |

0.045 |

0.045 |

|

S |

0.030 |

0.030 |

AISI 304 stainless steel vs 18/10: Corrosion Resistance

304 SS grade offer exceptional corrosion resistant due to adequate amount of carbon that helps to form a protective layer for an extended period resulting in the prevention of water and oxygen to react with the surface. On the other hand, 18/10 grade SS lack this thing therefore more prone to corrosion comparatively. However, suitable for mild environment.

18/8 Stainless Steel vs. 304 Stainless Steel: Physical Properties

Below are some of the physical properties of 18/8 and 304 SS grade:

Density

18/8 SS and 304 SS grade has a density of around 7.9 g/cm³.

Melting Point

Both 18/8 SS and 304 SS grade has melting point ranges from 1,400 to 1,450°C.

Magnetism

Both grades are nonmagnetic in annealed condition therefore suitable for applications like food processing.

Thermal Conductivity

Both 18/8 and 304 SS grade has a low thermal conductivity of about 16 W/m·K making them suitable for heat resistant applications.

Coefficient of Thermal Expansion

18/8 SS as well as 304 SS grade constitute of a similar coefficient of thermal expansion which is 17.2 µm/m°C.

Electrical Resistivity

Likewise, both grades have almost same electrical resistivity of around 0.72 µΩ·m. Hence, suitable for non-conductive applications.

18/10 vs 304 Stainless Steel: Mechanical Properties

Mechanical properties comprise of a great importance in material structural integrity. Below is the description of major mechanical properties of both 18/10 and 304 SS:

Tensile Strength

18/10 SS demonstrates a tensile strength between 500 to 700 megapascals (MPa), which is like 304 SS which indicates their capability to withstand pulling forces.

Yield Strength

Both steel grades show similar yield strength of 200 to 350 MPa showing their ability to bear mechanical stresses without deforming permanently.

Compressive Strength

Both steel grades show similar compressive strength of 1000 to 1500 MPa showing their ability to bear compressive stresses without buckling occurs.

Shear Strength

18/10 SS demonstrates a shear strength between 300-500 MPa, which is like 304 SS which indicates their capability to resist shear forces that leads to material failure.

Young's Modulus

Both steel grades show similar young’s modulus of 190 to 210 GPa.

Shear Modulus

The shear modulus value for both 18/10 and 304 SS is 70-80 GPa indicating their resistance against shear deformation.

Fracture Toughness

18/10 SS grade comprises of higher fracture toughness as compared to 304 SS grade and is more resistant to cracking.

Elongation

Both steel grades have adequate amount of elongation i.e., 40-60% demonstrating their capability to stretch without failure.

Impact Strength

18/10 SS grade comprises of higher impact strength as compared to 304 SS grade showing their capability to absorb energy during sudden impact.

Resilience Modulus

The modulus of resilience of both these SS grades is comparable showing their capability to absorb energy as well as resistance against fatigue.

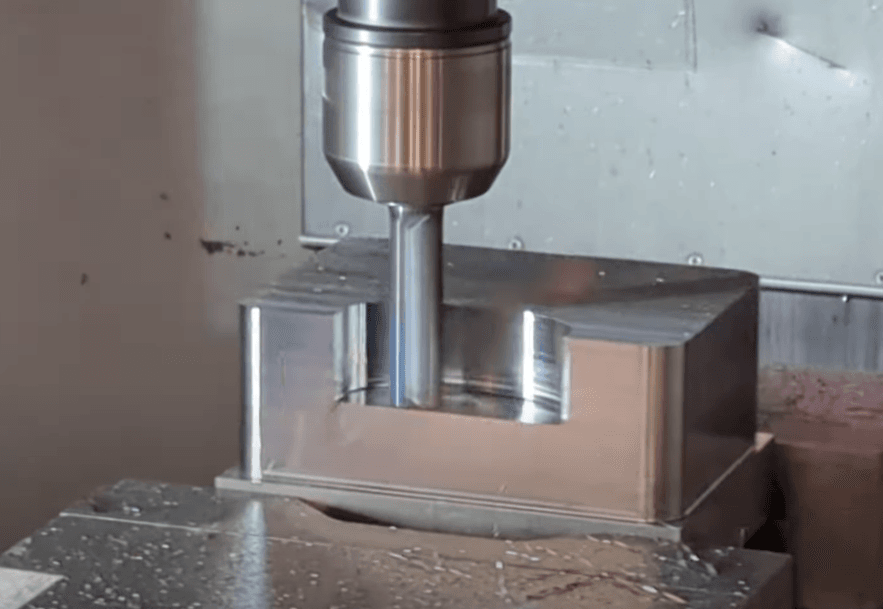

Machinability of 18/10 vs. 304 Stainless Steel

18/10 grade SS is difficult to machine as it constitutes of high Ni content while 304 SS has remarkable machinability especially in annealed conditions.

Differences Between 304 and 18 10 Stainless Steel

Table 2: Comparative analysis

|

Major Properties |

304 Grade SS |

18/10 Grade SS |

|

Chemical Composition |

18% Cr, 8% Ni |

18% Cr, 10% Ni |

|

Corrosion Resistance |

Excellent |

Better |

|

Strength |

Stronger, can resist deformation |

Less strong, can be deformed |

|

Magnetism |

non-magnetic |

magnetic |

|

Applications |

Food processing

|

Marine environments |

|

Cost |

More expensive |

Less expensive |

Is 304 or 18 10 Stainless Steel Better

It totally depends on your application requirements which grade is more convenient and sustainable. Both grades are exceptional in their own aspects yet there are some factors based on which both can be differentiated effectively. If your major requirement is good corrosion resistant along with high strength and good budget, then 304 SS is better. In contrast, if you want cost effective material along with durability for mildly corrosive environment then 18/10 SS is better choice.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Mild Steel vs Stainless Steel: Which is Better

Mild Steel vs Stainless Steel: Which is Better