10 Beginners Tips: How do you use a CNC Machine?

Dec 11,2024

Dec 11,2024

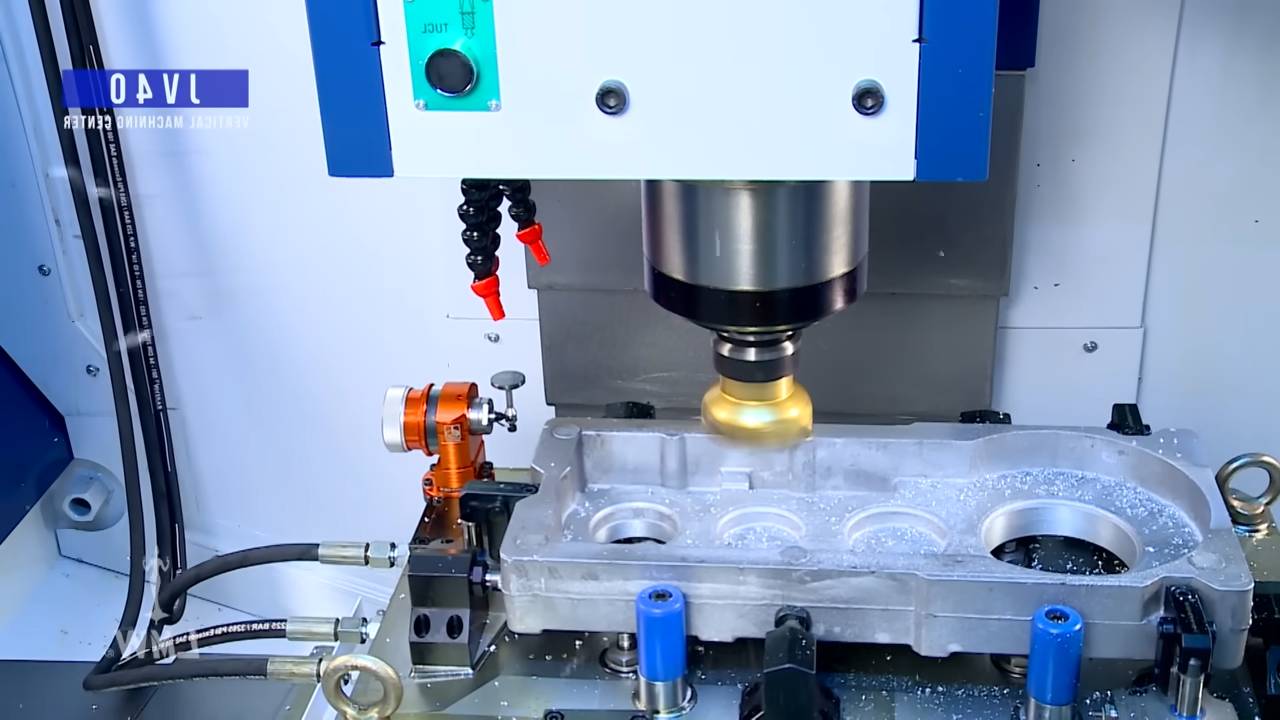

CNC machines have been used in manufacturing since the 1960s. They can perform multiple tasks, such as drilling, milling, tapping, etc., with perfect precision, making them versatile. These machines are used in many important industries like aerospace and automotive in which precision of dimensions is very important. This article is a guide to learning how a beginner can use a CNC machine efficiently.

What is a CNC Machine and How Does It Work?

A CNC machine is a manufacturing industry which is used to customize a part or component by cutting excessive material. It works through many cutting tools which are controlled by a CNC program i.e. G-code.

CNC Machining vs. CNC Routing: Key Differences

The key difference between CNC machining and CNC routing is the cutting speed.

CNC machining works with fast cutting speed and is used for hard materials like metals.

CNC routing is used for soft materials such as plastics and wood because of their lower or moderate cutting speed.

Essential Tools and Equipment You'll Need

The section will address the important tools and equipment related to a CNC machine. The most important tools include a spindle, tool holder, control board etc. Before using a CNC machine, CNC beginners must learn about the CNC basics, its essential tools and equipment.

CNC Machine Types: Milling, Turning, and More

There are many CNC machine operations which can be performed by using different CNC machines, for instance:

CNC Milling Machine: it is used for making complex shapes and parts.

CNC Tapping Machine: This machine helps make internal threads within the holes of parts i.e. nuts, screws etc.

CNC Drilling Machine: A CNC drilling machine is used to make holes in the parts.

CNC Turning Machine: This is mainly used to machine cylindrical parts.

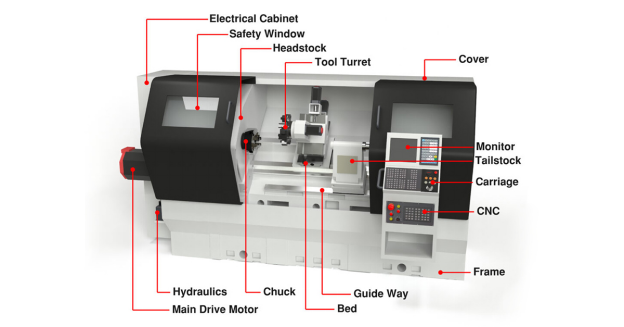

Key CNC Machine Components

The Key components of a CNC machine are:

Spindle: It is equipped with CNC machine tools i.e. cutting tools such as taps etc.

Tool Holder: This component holds the workpiece firmly for machining.

Control Panel: It consists of all the keys which control the functionality of different tools during work.

Tool Turret: It holds and rotates the tools for machining.

Chuck: It holds the workpiece ensuring the safety and stability of the workpiece.

CNC Machine Software Overview

To run a CNC machine, CNC software is very important and can be CAM (Computer-Aided Manufacturing). The primary function of this software is to convert a 3D design into a readable format for the machine. Further, it controls the CNC machine tools and the changeover of a workpiece.

How do You Operate a CNC Machine?

If you are a CNC beginner and want to operate a CNC machine, it is not very difficult. Make a 3D design of the required shape by using CAD software, convert it into a readable format through CAM software, and then feed the spindle speed etc.

Tip #1: Understand What CNC Machines Can Do

For CNC beginners, the very first tip is to know why these machines are important and in which applications they are useful.

Common Applications of CNC Machines

The most common applications of CNC machines are found in the aerospace industry to make important components such as landing gear parts, satellite parts etc.

The surgical tools and prosthetics are manufactured through CNC machines.

In the automotive industry, gearbox cases and engine blocks are made by CNC machinists.

How CNC Machines Benefit Your Projects

CNC machines are beneficial in your projects by saving time for manufacturing, keeping the precision machining, tight tolerance of the components, ensuring the safety of humans during work etc.

Step 2: Understanding CNC Programming Basics

A CNC machinist uses a CNC program to machine the parts, that’s why CNC beginners must learn the basics of this program.

What is G-Code and How to Use It?

Geometric Code is a programming language which uses its commands to control the spindle speed and movement of the tools and the workpiece. The data such as how fast tools need to cut the material etc. is stored in the form of a sequence of commands

The Role of CAM Software

This software converts the 3D design of the required parts into a readable format for the G-code. This conversion is important to work.

Tip #3: Select the Right CNC Machine for Your Job

Multiple versions of CNC machines are available on the market, which is why you are advised to choose the machine according to the respective application.

Types of CNC Machines: Milling, Turning, and More

CNC Milling Machine: it is used for making complex shapes and parts.

CNC Tapping Machine: This machine helps make internal threads within the holes of parts i.e. nuts, screws etc.

CNC Drilling Machine: A CNC drilling machine is used to make holes in the parts.

CNC Turning Machine: This is mainly used to machine cylindrical parts.

How to Choose Between a CNC Router and a CNC Mill

If your parsofte from a hard material like metals, then choose a CNC Mill and use a CNC router for the soft materials like wood and plastic.

CNC Machine Setup Pre-Operation Checklist

It is always better to check the setup before starting work. Any error during the work can lead to serious issues such as material waste, human injuries etc. Check the sample orientation etc. before starting the work.

Step 4: Preparing Your Materials

Preparation of materials before CNC machining includes checking their mechanical properties, their initial design etc.

Types of Materials for CNC Machining

Tough materials such as low carbon, stainless steel, polymers etc. are better for machining because of their toughness property. Materials such as high-carbon steel or composite are difficult for machining because of brittleness.

How to Secure Your Workpiece on the CNC Machine

The workpiece is secured by tightly fixing the workpiece on the tool holder and chuck tools.

Safety Considerations During Material Setup

- Check the orientation of the workpiece and cutting tools before working.

- Use Personal Protective Equipment (PPE)

- Make sure for daily inspection of your machine before working

- Correctly feed the data into software

Step 5: Setting Up the CNC Machine

It’s an essential step before starting work, which is addressed here.

Machine Setup: Installing the Tooling and Materials

CNC machining starts with installing the tools and materials. First, check the machine is off, then select the tool according to the material and application. Install tools and materials carefully and make sure the double-check by pushing both the tools and materials.

Comprehensive CNC Machine Safety Precautions

- Check the lighting of the workspace

- Use PPE

- Daily inspection of the machine

- Check the fixing of the tools and workpiece

Homing the CNC Machine: X, Y, Z Axes

Homing the CNC machine means the reference point is set to move the X, Y and Z axes. It provides a reference point for accurate movement of cutting tools.

Setting Tool Offsets and Calibration

Tool offsets include tool length and diameter offsets. Calibration means fixing the workpiece to the zero position before starting the work. This calibration and setting tool offsets ensure the precision of the cutting.

Step 6: Loading the CNC Program

It is the base of CNC machining. Different CNC programs are used for different operations such as G-code for CNC milling etc.

Loading Your Design File to the CNC Machine

The 3D design is not directly installed into the CNC machine, first, it is converted into a readable format by using CAM software then it is loaded into the machine through the CNC program.

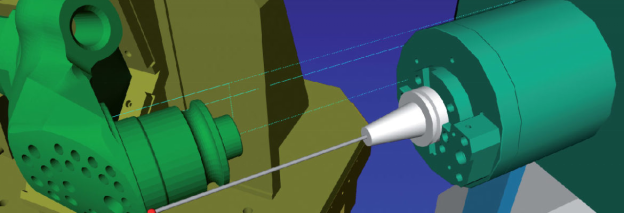

Verifying the G-Code

It is important to verify the G-code to avoid the risk of errors during the work. You can verify your G-code by using G-simulators. These simulations show the working of tools visually. If any error occurs during the work, it can be removed before practically starting the work.

Simulation vs. Real-Time Execution

Simulations provide a visual representation of how a tool will work, its speed, rate of material removal, production etc. Real-time execution cannot be 100% as same as the simulation but the simulations provide an idea of what possible errors can occur or what the production rate etc.

Step 7: Starting the CNC Machine and Monitoring Progress

You can start the machining process by turning on the CNC machine when all these steps are executed. Once, the machine is started, it is important to check continuously the working to avoid issues.

Running the CNC Program

You can start your CNC machine running by installing the program and turning on the machine. The Control Panel component is important to control the features of the CNC machine.

Monitoring the First Few Cuts

If a cutting tool is not working properly, its signs can be seen through the first few cuts. The finish of these cuts provides an idea of working. The rough cuts mean the tools are not working accurately.

How to Pause or Stop the CNC Machine Safely

In an emergency, you can pause or stop the CNC machine by pushing the red button on the control panel. To stop working after completion, first turn off the machine, then wait for the spindle to stop completely. Then remove the cutting tools. Clean the machine.

Step 8: Troubleshooting Common CNC Issues

These common issues include overheating, workpiece or tool vibration, power supply issues etc.

Identifying Tool Wear and Breakage

There are many ways you can identify the tool wear and breakage by changes in speed, sounds, the vibration of the spindle and workpiece, sensing the temperature, and visual inspection.

Resolving Alignment and Cutting Errors

It is important to resolve the issues of alignment and cutting errors instantly to avoid some serious loss. You can resolve the issue by pausing the process.

Addressing Machine Failures

It is important to address if any failure in the machine occurs. This address will include the cause and prevention of the failure. It will help avoid further failures.

Step 9: Post-Processing Your Workpiece

The following steps are included in the post-processing of your workpiece:

Removing the Finished Part from the CNC Machine

When the processing is completed, turn off the machine and remove the finished workpiece.

Cleaning and Inspecting the Finished Part

The cleaning and inspection of the finished part is significant because it would ultimately cause failure when used in the application.

Deburring and Surface Finishing Techniques

Deburring techniques include thermal or electrochemical deburring. The finishing techniques include grinding, polishing, etc.

Step 10: Maintaining Your CNC Machine for Longevity

These are the some of easy techniques for maintaining your CNC machine for longer times:

Regular Cleaning and Lubrication

Regular cleaning removes dirt, debris etc. Lubrication helps reduce friction during the work. Debris and friction decrease the performance of cutting tools.

Checking for Wear and Tear

Fast spindle speed causes wear and tear on cutting tools, that’s why daily checking is very important.

Preventive Maintenance Tips to Avoid Downtime

- Daily inspections of the machine.

- Ensuring the correct voltage supply.

- Providing lubrication at the right times.

Tuofa China CNC Machining for Prototyping and Production

Toufa China CNC Machining is the best service provider company for prototyping and production. We have the most skilled CNC machinists who will ensure the precision and accuracy of the parts and prototypes. We will deliver your products within a short time and with the best prices.

FAQs About Using a CNC Machine

How Long Does It Take to Learn CNC Machining?

Learning the basics of CNC machining will not take long enough. Daily practice of these basics will make you a master of CNC machines. It would take 2-3 months to learn CNC machining.

What Are the Most Common Mistakes Beginners Make?

Beginners make mistakes like errors in coding, orienting the workpiece wrongly, trying to do more than learnt etc.

Can CNC Machines Be Used for Home Projects?

Yes, small CNC machines are available in the market at low costs which take up small spaces.

How Much Does a CNC Machine Cost?

The cost of a CNC machine depends on its features and size. Its average cost is in the range of 30,000$-60,000$.

Basic CNC Cutting Strategies for Beginners

Learn a little CNC basics daily and then practice it regularly.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

CNC Router vs Milling Machine: A Complete Comparison

CNC Router vs Milling Machine: A Complete Comparison