What does SFM Mean in Machining for Common Materials?

Nov 26,2024

Nov 26,2024

SFM (Surface Feet per Minute) is of great importance to machinists for ensuring the precision in machining and longevity of the tool lifespan. It is actually a measure of the tool speed relative to the workpiece. Let’s discuss it a bit more!

What does SFM Stand for in Machining?

SFM is the abbreviation of “Surface Feet per Minute”. It is analogous to the effective speed of the tool as if it is travelling in a straight line. It helps the machinists and CNC specialists to determine the correct RPM (revolutions per minute), feeds and speeds spindle speed settings and the right tool for a specific material. Thus, it is quite pertinent for setting the CNC and lathe machine parameters optimally to boost up the performance of the tool and the precision of the operation.

Is SFM easy to use?

Yes! For a machinist it’s not a big job. There’s only a little formula that needs to be used.

What are the Units Used to Measure SFM?

Conventionally, SFM is an imperial unit as in the early days (1950s), machining was first adopted in the USA, the Americans used the imperial unit’s system that uses “feet”. But, later on as the machining became common on other parts of the world where people were more accustomed to the SI system of units, they began to use “millimeters” instead of “feet”. So, it became “Surface Millimeters per Minute".

For conversions:

Surface ft/minute = ![]()

Surface mm/minute = Surface feet per minute x 304.8

SFM to RPM Calculations

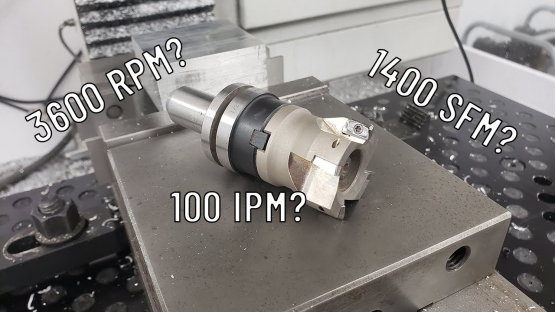

Is SFM the same as RPM?

As already discussed, SFM uses “surface feet” in contrast to RPM which uses “revolutions”. RPM depends mainly on the motor specifications and thus the spindle speed. But SFM is the actual measure of the distance that the tool covers per minute. Although both are directly proportional to each other but they cannot be used in place of each other. There are many other factors which affect the SFM like workpiece diameter or tool diameter. The chip load formula and IPM formula are also different from SFM and RPM but they also depend on the feed rate.

How to Calculate SFM in Machining?

The relationship between SFM, spindle speed (RPM), and the diameter of the tool or workpiece is expressed as:

SFM = ![]()

Where:

- D: Diameter (in inches) of the cutting tool (for milling) or workpiece (for turning)

- RPM: Spindle speed (revolutions per minute)

- 12: Conversion factor to go from inches per minute to feet per minute

Here is an example to explain it better:

Let’s say that in our case the workpiece diameter (D) is 12 inches and the RPM is 1500, then the SFM would be:

SFM = ![]()

SFM = 4712.38 SFM

Factors that Influence SFM in Machining

While, there could be many factors that influence SFM in machining, we’ll be discussing the material type, tool geometry and machining capability:

1. Material type:

Material characteristic like hardness, thermal conductivity and chip formation influence thee SFM in machining. For e.g relatively hard materials like titanium require a low SFM in comparison to softer materials like plastics or aluminum, due to higher resistance to cutting.

Materials with a good thermal conductivity like copper require a low SFM in contrast to materials with low thermal conductivity like stainless steel, due to better heat dissipation.

Materials like free machining steels have good chip formation characteristic so they tend to behave well under relatively high SFMs

2. Tool characteristics:

Tool characteristics like geometry, rake angle and even material properties can affect the SFM. These will be discussed in details

3. Machining capabilities:

A machine’s capabilities directly impact the achievable SFM. High RPM machines allow greater speeds for smaller tools, while limited RPM can restrict larger tools. Strong, rigid machines handle higher SFM without vibration, but less rigid ones need slower speeds for accuracy. Efficient coolant systems reduce heat and allow faster cutting, while poor cooling forces slower speeds. Advanced CNC controls optimize SFM in real time for better performance and a better material removal rate (MRR).

The Role of CNC Tools in SFM Calculation

The selection is the right CNC cutting tool is of paramount importance to enhance and optimize chip and material removal with precision and cost effectiveness. Here are some of the parameters that should be considered:

1. Cutting Tool Materials

High Speed Steel (HSS): Tools made with this material generally require a low SFM to prevent rapid wear. But it can be a good balance between cost and effectiveness

Carbide Tools: These tools can withstand high temperature and these show resistance in wearing. Thus, a higher SFM can be employed.

Ceramics and Cermets: These tools offer an even more SFM than the HSS and Carbide tools due to more tolerance to heat and wear. These are employed in high speed machining applications.

2. Tools Coatings:

- Hard coatings like TiN or TiAlN, severely enhance the surface characteristics like coefficient of friction and wear resistance which in turn allows for larger SFMs in CNC machining applications.

3. Tool geometry:

- Larger diameter tools allow for a smaller SFM in comparison to the smaller diameter tools. But the chip load in this case might be more in CNC machining.

Common Mistakes and How to Avoid Incorrect SFM Settings

Optimum SFM setting are desired for maintaining a good precision, good surface finish, good MRR and longevity of the tool lifespan. Here are the common consequences of the incorrect settings:

If SFM is too high:

- Excessive heat generation due to high friction

- Low tool life due to tip radius becoming blunt quickly

- Material deformation due to excessive heat

- Thermal expansion leads to dimensional errors

- Surface finish degradation

If SFM is too low

- Low material removal rate (MRR)

- Excessive pressure on the tool: Its lead to low tool life

- Tool chatter

How to Adjust SFM for Different Materials?

When adjusting the Surface Feet per Minute (SFM) for different materials, it's essential to consider factors like tool type, material hardness, and cutting conditions. Here’s a general approach to adjusting SFM for various materials and processes:

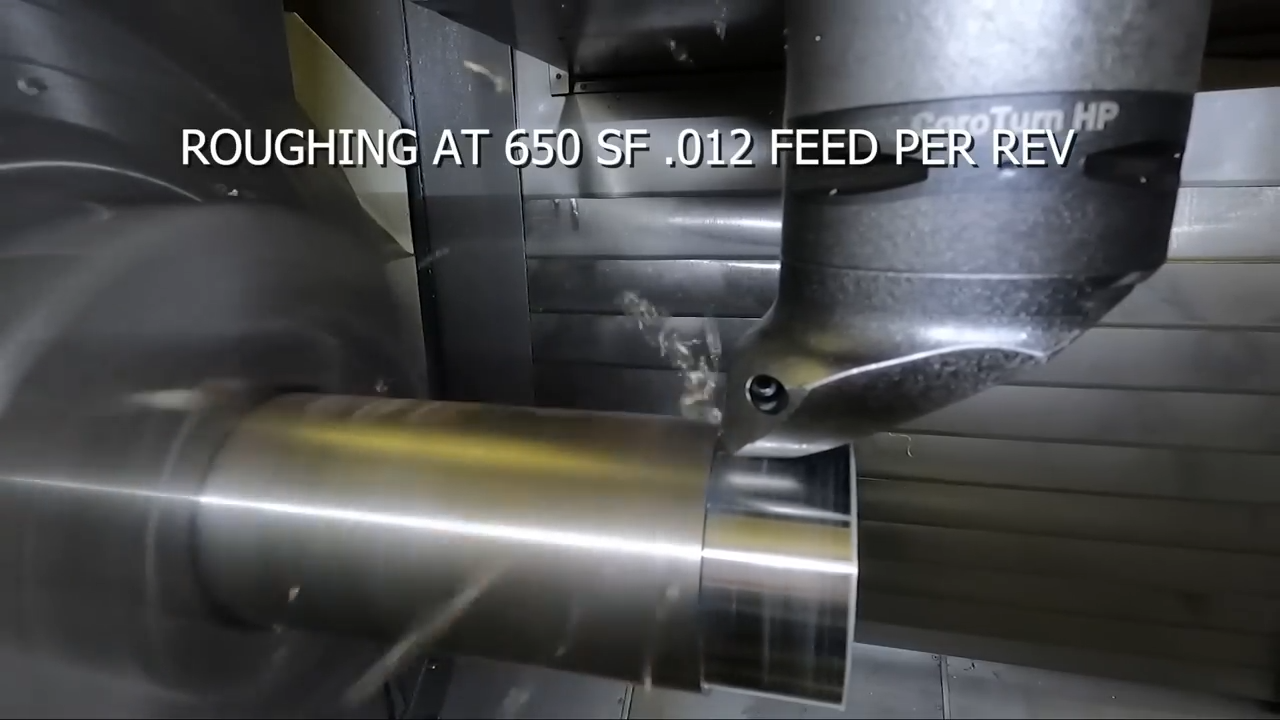

SFM for Turning 303 Stainless Steel

For turning 303 stainless steel, a variety of factors like tool material and the type of cut (continuous vs. interrupted) can affect the SFM. Typically, carbide tools allow for higher SFM, but if using HSS tools or making interrupted cuts, the SFM should be reduced. Coolant usage is also recommended to control heat buildup.

SFM for Drilling 304 Stainless Steel

Drilling 304 stainless steel requires careful adjustments depending on the tool material and size. For larger drills or when using HSS tools, reducing the SFM is advised. Carbide tools and coatings allow for higher speeds, and using peck drilling can help control heat during the process.

SFM for Milling 4140 Steel

Milling 4140 steel benefits from higher SFMs when making lighter cuts with carbide tools. For deeper cuts or setups with lower rigidity, reducing the SFM will help avoid tool wear and improve machining stability. Using coolant or air cooling can also help manage temperature and prolong tool life.

SFM for Turning 4140 Steel

Turning 4140 steel requires adjusting the SFM based on the material's condition. For annealed 4140, higher SFMs are suitable, but for hardened material or low-rigidity setups, the SFM should be lowered. Coolant is crucial to prevent overheating and improve cutting efficiency.

SFM for Cutting 6061 Aluminum

6061 aluminum is relatively soft, so higher SFMs are appropriate, especially when using polished carbide tools. However, for larger tool diameters or to avoid tool chatter, reducing the SFM might be necessary. Coolant, whether mist or flood, is recommended to reduce heat and improve surface finish.

Optimal SFM Chart for Common Machining Materials and Processes

|

Material & Process |

Optimum SFM Range (ft/min) |

Adjustment Guidelines |

|

Turning 303 Stainless Steel |

300 - 600 |

Use carbide tools for higher SFM; reduce for HSS or interrupted cuts. Coolant recommended. |

|

Drilling 304 Stainless Steel |

50 - 100 |

Increase with carbide tools and coatings; reduce for larger drills or HSS. Use peck drilling for heat control. |

|

Milling 4140 Steel |

250 - 400 |

Increase for light cuts and carbide tools; reduce for deeper cuts or less rigid setups. Use coolant or air cooling. |

|

Turning 4140 Steel |

300 - 500 |

Higher SFM for annealed material; reduce for hardened 4140 or low-rigidity machines. Coolant is essential. |

|

Cutting 6061 Aluminum |

600 - 1,200 |

Increase with polished carbide tools; reduce for larger tool diameters or chatter. Use mist or flood coolant. |

Tools for Accurate SFM Calculations

A list of commonly used tools is give below for the readers:

- FSWizard

- Machinist’s Calculator Pro (Please see the Youtube Link)

- HSMAdvisor

- G-Wizard

Frequently Asked Questions (FAQs)

How does surface speed relate to SFM?

SFM and surface speed are directly proportional to each other. The more the surface speed the more the SFM and hence the more the material removal rate (MRR) in the optimum range of SFM.

What happens if SFM is too high or low?

Any deviation from the optimum range of SFM results in lack of precision, imperfections on the surface, dimensional inaccuracies, increase in cost, frequent need to change the tool and material deformation.

How do I choose the right SFM for my CNC machine?

Keep a consideration on parameters like material of workpiece, material of tool, geometry of tool and the dimensions of the workpiece. An example of the SFM for common materials is given in the table above. To convert RPM to SFM, use the formula given above.

Can SFM vary during the same machining process?

Yes, SFM also depends on the diameter (D), if it changes, SFM changes.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

CNC Tapping: Process, Benefits and Applications

CNC Tapping: Process, Benefits and Applications