What is a Machining Center? 2025 Complete Guide

Nov 25,2024

Nov 25,2024

A Machining centre (MC) is a part of a CNC machine, which is equipped with many cutting tools. In any manufacturing industry, you would find its usage because of its useful features for the preparation of components or parts. This article would be a source of information for you regarding every aspect of the machining centre.

What is a Machining Center?

A machining centre consists of many cutting tools which remove the excessive material from the workpiece to provide the required shapes. These cutting tools help perform operations like boring, milling etc.

Origins and History of Machining Centres

The first CNC machine was made in 1952 by German scientists. At that time, it was used only for making saws files, and chisels. The features of automation and machining centre were installed in the late 1980s.

Advantages of Using Machining Centers to Manufacture Parts

The advantages of using machining centres are:

- Fast machining due to ATC (Automatic Tool-changing).

- The production of the prepared parts is higher.

- Greater accuracy and efficiency for tight tolerance.

Key Components of a Machining Center

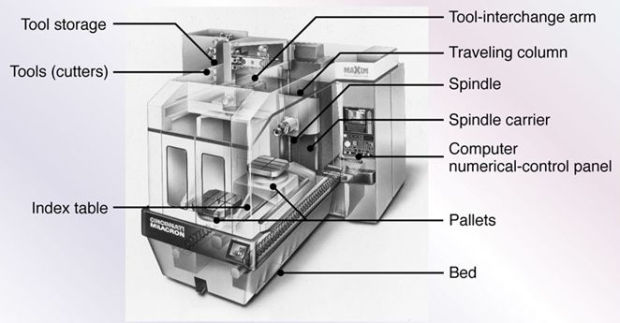

The given figure represents many components of a machining centre, but the key components include tool storage which store various cutters, spindle which controls the rotation speed of these cutters, pallets which are helpful in changing the workpiece and the bed on which machining of the components is done.

What Operations are Performed in a Machining Center?

- Different drill bits are used to make blind or through holes in the components. This process is called Drilling.

- Different taps are used to make internal threads within the pre-drilled holes i.e. called tapping.

- The diameter of pre-drilled holes is enlarged by a boring process in the machining centre.

- A milling processin the machining centre is performed to make complex shapes by cutting.

Types of Machining Centers

Let’s have an overview of different types of machining centres:

Vertical Machining Centre

This type of machine centre is famous for providing tight tolerances. In this machine, the orientation of the spindle is vertical to the workpiece. Features such as ATC and APC are helpful for the machining of small parts. Due to vertical orientation, the removed material remains on the workpiece, which means is removed manually.

Horizontal Machining Centers (HMC)

The spindle is oriented in the horizontal direction as compared to the vertical machining centre. This machine has one advantage over the vertical VMC which is you do not need to remove material chips from the workpiece, the material does not accumulate on the surface. Another advantage is that this machine can perform operations on 3-4 surfaces of the workpiece at a time. This machine is worth it for its high-precision machining.

In summary, both machines have one technical difference and that is the orientation of the spindle.

5-Axis Machining Centers

A 5-axis machining centre can work at the same time in 5 different directions of a workpiece. A tool storage component stores various cutting tools which are used in performing different tasks like boring, milling etc. Every CNC machine works by using CNC software, this software controls the tools of the CNC machine.

This machine comes with more uses than any other machine. To do undercutting for different parts is a difficult task, but using this machine would be quite easy for you. Custom machining solutions are not possible with other machines, but 5-axis machines excel in this task as well. Due to its brilliant features, the efficiency, precision, quality and production of the parts is greater than any other machine. .

Machining Center Price

If you are planning to build a manufacturing industry of different parts of the automotive or aerospace field, you would need these machines for sure. Every machine has its own features, which decide the price. The second thing is the brand of these machines in pricing. Here in this section, the prices of three commonly used machines have been mentioned after analyzing the market.

Vertical Machining Centers (VMC)

50,000 $ - 60,000 $

Horizontal Machining Centers (HMC)

52,320 $ - 57,900 $

5-Axis Machining Centers

401,428 $ - 410,000 $

This analysis shows that the 5-axis machining centre is the most expensive because of its versatile uses.

What Industries Use Machining Centers?

The following section addresses some of the industries where the machining center is used.

Aerospace Industry

In this industry, safety concerns are higher than in any industry, to meet high standards of safety, highly precise parts are required. To tackle those concerns, advanced technology like machining centres is used to prepare parts of complex shapes such as turbine blades, fuselage etc.

Automotive Industry

This is the second most critical industry after aerospace. Machining centre machines are used to prepare complex shape automotive parts which are brake systems, chassis, engine components etc.

Oil and Gas Industry

The parts including pump parts, riser systems, valve bodies etc. are prepared through the machining centre machines. These parts are useful in exploring the resources of oil and gas and production.

How to Know if My Parts are Manufacturable/Machinable

There are certain criteria to be fulfilled before machining and manufacturing. Be careful regarding the geometry of the workpiece, processes and process optimization, tools and their availability and most important, the material of the workpiece. The mistakes in selecting even a single wrong tool can cost you in waste of money, time and energy.

FAQ

What is the difference between a machining centre and a turning centre?

A CNC machine can perform both operations i.e. milling and turning. After reading this article, you would have an idea that a machining centre can perform operations like boring, milling etc. A tuning centre is used to machine cylindrical workpieces through turning or facing etc.

What is the difference between a milling machine and a machining centre?

Both are different things. The main differences include:

|

Machining Centre |

Milling machine |

|

A part of a CNC machine can operate automatically. |

It works manually. |

|

Operations such as boring, milling, drilling and tapping can be performed. |

Only specified for milling operation to remove excessive material to provide complex shapes. |

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What does SFM Mean in Machining for Common Materials?

What does SFM Mean in Machining for Common Materials?