High Carbon Steel Knives: Pros and Cons

Oct 22,2024

Oct 22,2024

Quality knives require both hardness and sharp edges. In this regard, high-carbon steel does the job. This article presents the data on why high-carbon steel knives are common and what are their drawbacks.

What is High Carbon Steel?

High-carbon steel is an alloy which contains higher amounts of Carbon i.e. 0.6% - 1.5. High-carbon steel is used where high hardness is required for instance in making blades, springs, knives etc. Due to higher amounts of C, this alloy is brittle.

Does High Carbon Steel Knives Break Easily?

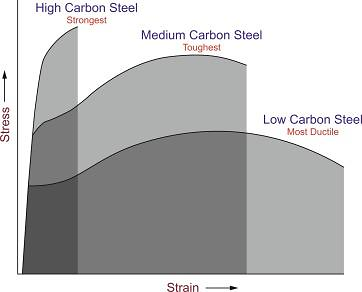

High-carbon steel is a brittle material due to the high amount of carbon. C content increases the yield strength, as you can see in the following graph, high-carbon steel has the highest yield strength than others, which means it is not easy to break them.

Is High Carbon Stainless Steel Good for Knives

A good knife requires the following characteristics:

- High strength and hardness

- Knife Sharpness

- Durability

- Rust Resistance

High-carbon steel stands with these properties. Rust is the main issue, but in the following section, different methods are discussed to prevent it.

How to Clean High Carbon Steel Knife

You can clean your high-carbon steel knives with baking soda or wrap them in vinegar.

How to Care for a High-Carbon Steel Knife

Dry high-carbon steel knives well after use. Secondly, coat a layer of oil which will enhance rust resistance.

How to Tell if a Knife is High Carbon Steel

Scratch the knife then place it for a day and night, if it rusts then it is a high-carbon steel knife. Any stainless steel or low carbon steel knife remains shiny after long usage. Place one or two drops of lemon juice on the steel and leave it to sit for a while. If the lemon juice produces a black spot, then the chances are it is most likely carbon steel.

Does High Carbon Steel Knife Rust

If proper care for high carbon steel is not taken, then the chances of rust are high. Fe reacts with Oxygen and air in the environment, and forms rust.

How to Keep High Carbon Steel Knife from Rusting

Apply a coat of mineral oil, olive or vegetable etc. Dry the knife well after use. Place it in a dry place. Clean it regularly.

High Carbon Stainless Steel Knife Pros and Cons

The pros and cons of high-carbon steel are discussed below:

Edge Retention and Sharpness

High-carbon steel knives are very hard and sharp due to the high percentage of C i.e. 0.6% - 1.00%. High carbon steel knives have the quality of re-sharpen which helps in edge retention.

Due to its higher hardness, the knife will chip and break if it accidentally hits a hard surface. Rust is another issue if proper care is not taken. Rust affects knife performance badly.

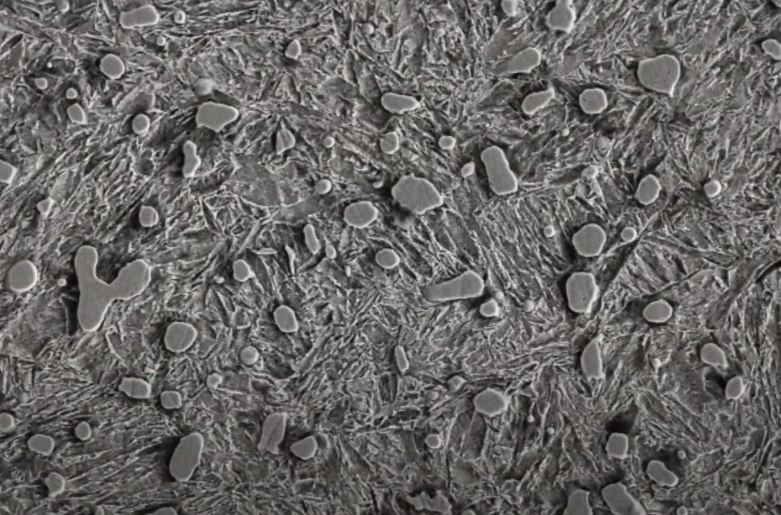

Heat Treatment for High Carbon Steel Knives

High carbon steel is first heated to 780ᵒC to 850ᵒC temperatures. Then it is quenched in water or oil according to the hardness requirement. This treatment helps in achieving a hardness of 55 to 62 HRC. Then tempering is performed to reduce the brittleness and induce some toughness.

Is 440C Steel Good for Knives

It is a grade of stainless steel which comes with good wear and corrosion resistance due to 16-18% Cr content. It is easy to heat treat. It has good strength and durability. All these properties are required to make a good knife.

Is 440A Steel Good for Knives?

This steel grade stands with high corrosion resistance but with moderate strength in the 440 family. It is easy to machine and good for making performance knives.

1095 High Carbon

1095 high carbon shows higher hardness and wear resistance in all steel grades. It is used in making weapons like swords, and knives.

1070 High Carbon

Lower carbon content than 1095 grade steel. Offers a balance between durability, hardness and edge retention.

1080 High Carbon

It is considered the favorite grade of steel because of its high strength, hardness and toughness. Carbon content is greater than 1070 but lower than 1095 grade.

Types of High Carbon Steel for Knives

There are various types of steel which are used in making different knives for different purposes. Every grade affects the knife’s performance.

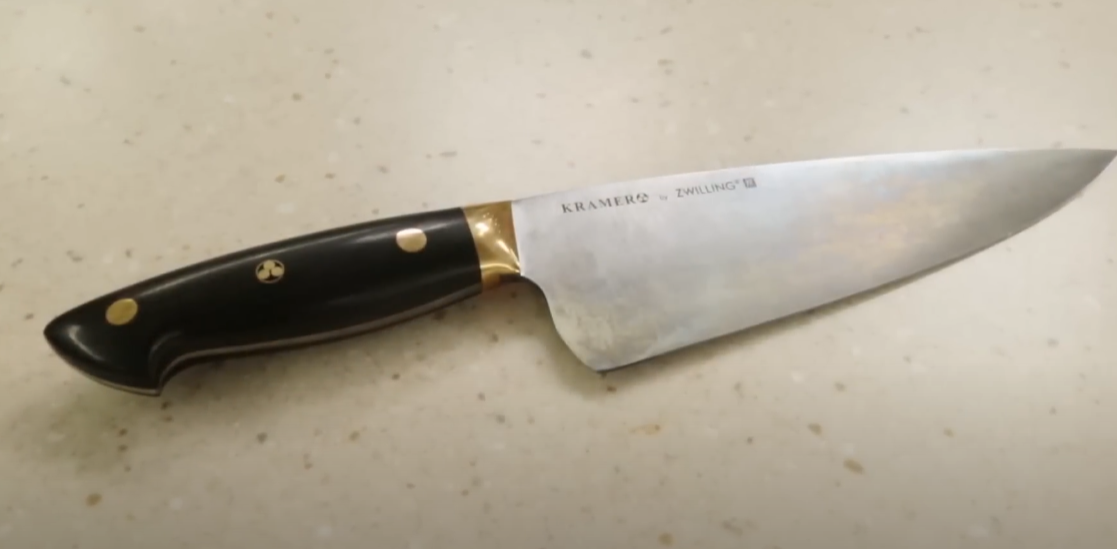

Blades

High-carbon steel blades are used for chef knives, pocket knives and utility knives.

Knife Set

The knife set contains high-carbon steel chef knives which have high hardness and wear resistance.

Kitchen Knives

Most kitchen blades are composed of high-carbon steel due to their increased ability to maintain edges.

Boning Knife

Due to their adaptability and spotless, fresh-cut, high-carbon steel is an astounding decision for bone knife creation.

Pocket Knife

Pocket knives are typically made of high-carbon steel due to their sharpness.

Best High Carbon Steel for Knife Making

1095-grade steel is regarded as the best choice for blades because of its goof balance of durability and sharpness.

Best Steel for Kitchen Knives

VG-10 steel is a Japanese-grade steel that excels in edge retention, sharpness, and erosion resistance. It is one of the most incredible choices for kitchen blades.

High Carbon Steel Knives vs Stainless Steel

High Carbon Steel knives excel in edge retention and stainless-steel knives are brilliant against corrosion attacks.

Comparison with Other Steel Types

High Carbon Steel vs Low Carbon Steel for Knives

Carbon is an important factor for hardness and machinability. High-carbon steel has greater hardness and wear resistance but is difficult to machine as compared to low-carbon steel.

High Carbon Steel vs AUS-8 Steel

High-carbon steel is sharp, yet it rusts quickly. AUS-8, the Japanese grade, is rust-resistant and easy to deal with, however, needs sharpness.

High Carbon Steel vs S30V Steel

S30V steel excels in rust resistance and toughness. It requires lower maintenance.

High Carbon Steel vs VG-10 Steel

VG-10 steel has Cr content in its composition which makes it corrosion resistant and has good sharpness as well.

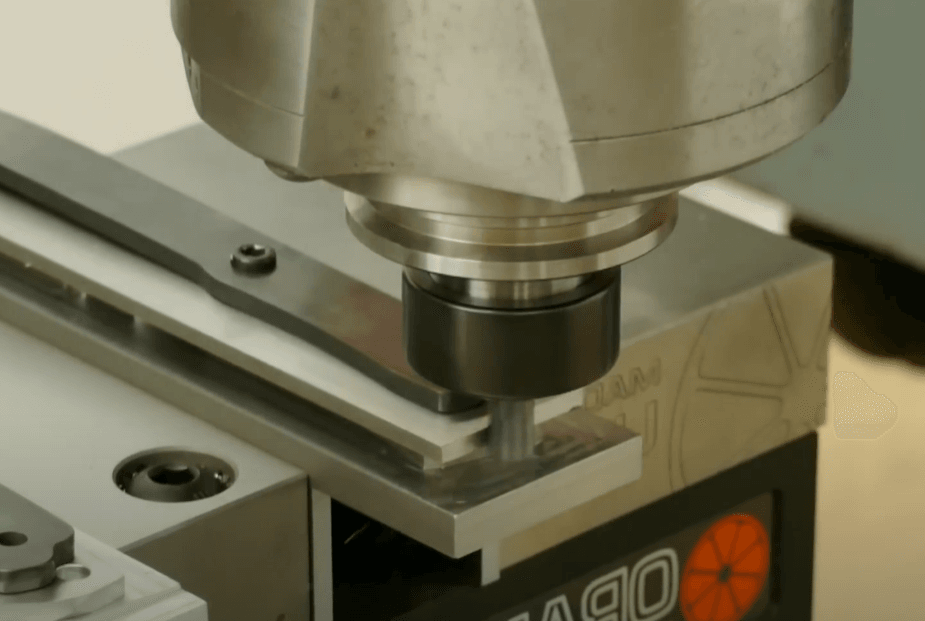

CNC Machining High Carbon Steel Knives

It is very difficult to machine high-carbon steel material because of its hardness and brittle nature. CNC machining stands with the best possible choice to machine knives because of its versatile features i.e. precise and tight tolerance cuts.

Patina Formation on High Carbon Steel Knives

Patina is a thin layer which forms on high-carbon steel products over some time. It forms when high carbon knife is exposed to air and moisture.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Black Oxide Stainless Steel: A Comprehensive Guide

Black Oxide Stainless Steel: A Comprehensive Guide