Damascus Steel vs Stainless Steel: Which is Better?

Aug 07,2024

Aug 07,2024

Stainless steel used in knives has its own description. It changes with the types of knives. Some of them are simple and plain and some have patterns over its blades. It’s not only the design that changes but also the type of steel, manufacturing process and the use of knives, that are also different. In this article, you will see the two main knives steel comparison. That will be stainless steel and Damascus steel.

What is Damascus Steel?

It is a multi-layered steel. It is known for its unique wavy pattern etched in steel. Steel knives are made from round bars and billets nowadays. This knifemaking material is way more expensive than ordinary steel. This is due to blade material, blade durability, intricate pattern and high-performance steel.

How is Damascus Steel Made

The traditional, ancient real Damascus steel is made from metal. This is known as Wootz steel. The name of the alloy is on the City of Damascus in Syria. Modern Damascus steel is made of high carbon steel and softer stainless steel. high carbon provides blade durability and stainless steel provides corrosion resistance and durability. It is made into rods called Damascus rods and billet and then converted into knifemaking materials.

The Science Behind Damascus Steel Patterns

The Damascus steel pattern is due to the folding and hammering technique used to create knifemaking materials. The blade material has an intricate design made from high-performance steel that makes it hot-selling kitchen item. The striking patterns and the technique used in knives make it costly and expensive than the ordinary knives.

Damascus Steel Terminology Explained

There are many other names used for Damascus steel in different languages. In 13th century, it was called Persian-forges Damascus steel used to make swords. Wootz (Indian) steel, Pulad (persina), Bulat Russian, Bintie (China), Fuladh (Arabic) are the ancient names used for high carbon crucible steel. Damascus knives are known as folded steel, layered steel, and pattern-welded steel.

Composition

The composition of Damascus knifemaking material is:

|

Elements |

Percentage |

|

Carbon |

1.48% |

|

Manganese |

0.006% |

|

Silicon |

0.0082 |

|

Phosphorus |

0.192% |

|

Sulfur |

0.005% |

Common Steel Types

Common steel grades used as Damascus knifemaking materials are ASTM-203E, 1084, 1095, W-2, 15N20 (L-6), O1 and 52100.

Is Damascus Steel Good?

Damascus steel has moderate ductility, hardness and durability. The edges of knifemaking materials are longer than ordinary steel knives. The aesthetics of Damascus steel are also superior to steel knives.

Is Damascus Steel Strong

Yes, Damascus steel and strong and durable. It is also suitable for heavy duty applications. It has high resistance to fatigue, impact, shear, deformation and bending. The suitable areas for its application are heavy loadings and repetitive stress conditions.

Is Damascus Steel good for Knives?

Yes, Damascus steel is good knifemaking material. Damascus knives have a wavy pattern on its blade material which increases aesthetics. Damascus steel also has high corrosion resistance and durability due to high-performance steel

Decoding Stainless Steel

stainless steel, a high-performance steel, is one of the commonly used in almost every field and industry in the world. It is made of Fe, C, Cr, and a small number of alloying elements. These elements are Ni and Mo. Cr content is higher which increases the corrosion resistance. That is why it is a common alloy to make kitchen items like utensils, cutlery and all the above a good knifemaking material. However, the amount of Cr determines the blade durability in the material. For steel knives comparison, composition of steel is the important aspect.

Characteristics of Stainless Steel

Corrosion resistance

Stainless steel is known for its highest corrosion resistance among all steel. High chromium content creates a layer of oxide which protects it from rust. This makes the blade material long lasting and increases the blade durability. This high-performance steel not only uses in kitchen accessories but also in construction, automobile, aerospace, medial and pharmaceutical industries due to its corrosion resistance.

Durability

The blade durability of stainless-steel knives is expectational. These are perfect for cutting, chopping slicing the hardest or toughest material like meat. Carbon content also increases the sharpness in blade edges

Versatility

Stainless steel knives are perfect for any kind of task. Stainless steel itself is a versatile material that has high corrosion resistance, durability, high strength and toughness. Another important feature of stainless-steel knives is easy maintenance and easy to clean.

Damascus Steel vs Stainless Steel Which is Better?

To know which steel knife is better in performance, the knife steel comparison is made to draw

Weight

The density of stainless-steel knives is 7.5-8g/cm3. while Damascus steel knives have density of 7.93-9 g/cm3. Damascus steel knives can be heavier in weight than stainless steel knives.

Corrosion Resistance

Corrosion resistance of Damascus steel is less than stainless steel. stainless steel has higher chromium and less carbon content. This makes it durable and highly corrosion resistance. Damascus steel can also have longer life and durability if taken care properly and maintained properly.

Sleekness

Sleekness is higher in Damascus steel knives. Damascus knives are aesthetically pleasant and has a unique look due to its wavy pattern. While stainless steel knives have ordinary look and might attract only those who are interested in high durability and high-performance steel knife.

Mechanical Properties

stainless steel has higher mechanical properties. they are easy to maintain and durable than Damascus knives. However, Damascus knives have better look and blade material which has long lasting edge sharpness.

Cost Considerations

Damascus knives are costly than stainless steel knives. Damascus knives are made from a different technique having wavy pattern. This increases its labor cost. Also. It has stainless steel and carbon steel in its composition. These all factors when combined increase the cost of Damascus steel knives.

Sharpness, Edge Retention, and Durability

Sharpness and edges retention are better in Damascus knives. stainless steel knives have higher corrosion resistant. But the durability of both knives is almost equal.

Damascus Knives vs Stainless Steel

The knife steel comparison based on their types, and properties is as follows:

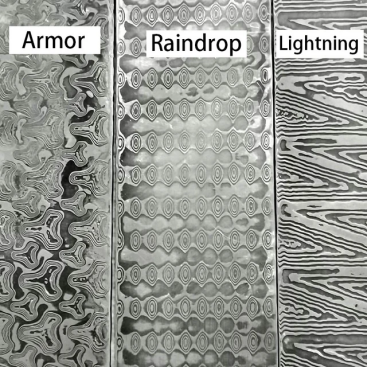

Knife types

Damascus steel knife is different based on its pattern. Common types are twist, ladder, raindrop. Wild, mosaic, herringbone. These patterns are depending on the integrity of steel structure, improving functional and aesthetic quality of blade material.

Stainless steel knives are Cronidur 30, X50CrMoV15, D2 / SKD11, MC66 / ZDP-189, SG2 / SGPS and VG10 (V-Gold 10). These are different based on the steel grade and properties of blade material.

Specific steel grades

The grade of knife steel comparison is depending on the chemical composition of steel.

Common steel grades used as Damascus knifemaking materials are ASTM-203E, AUS-8,1084, 1095, W-2, 15N20 (L-6), O1,440C, S30V, S35VN and 52100. Stainless steel knifemaking materials are Cronidur 30, X50CrMoV15, D2 / SKD11, MC66 / ZDP-189, SG2 / SGPS and VG10 (V-Gold 10).

Knife anatomy

Damascus knifemaking material is a multilayered material of steel. the blade material is folded and forged to make a unique pattern. Blade material is a high carbon steel with carbide and troostite layer. This increases the blade durability. While stainless steel contains chromium, nickel and molybdenum which increases the corrosion resistance of blade material. In the knife steel comparison, stainless steel has better corrosion resistance while Damascus knife has better aesthetics and finish.

Hardness scales

The knife steel comparison in terms of hardness, Damascus knives have slightly higher hardness. The Rockwell hardness of Damascus knives is 62-67HRC. While the stainless-steel knives have 58-62HRC hardness.

Blade finishes

Damascus knives are acid etched finished. The blade material is first heat treated and tempered. Then acid etching is done to bring out the pattern of Damascus knife. Mild acids like ferric chloride are used to etch the surface. while the stainless-steel blade materials are mirror polished, stonewashed, satin or brushed or blasted finished.

The knife steel comparison in terms of finishes, Damascus knife final look is more appealing than stainless steel knives.

Strengths and Weaknesses of Damascus Steel vs Stainless Steel

Strength and weakness of Damascus Steel

- Strength:

- The knifemaking material has remarkable edge retention

- aesthetically appealing pattern on blade material

- blade durability is higher if proper care is done

- weakness:

- Can undergo corrosion and rust

- Costly than ordinary knifemaking materials

- Requires proper maintenance to perform effectively.

Strength and weakness of Stainless Steel

- Strength:

- Balde material is highly corrosion resistant

- Easy to clean and maintain knifemaking materials

- Cost-effective and readily available

- weakness:

- edge retention is less than Damascus steel

- steel knife comparison in terms of finishes and aesthetics, it is less appealing than Damascus knifes

Damascus Steel vs Other Material

The steel knife comparison with other materials is as:

Damascus Steel vs Carbon Steel

Blade durability is higher in Damascus steel than carbon steel. The unique pattern and finishing of high-performance steel increase the blade rigidity.

Damascus Steel vs Japanese Steel

Damascus steel is famous for its unique patterns, strength and blade durability. Whereas Japanese steel is a conventional sword-making material. It has higher edge retention than Damascus steel. It is a high-performance steel and has better sharpness than Damascus steel.

Damascus Steel vs Tungsten

Tungsten and Damascus steels are different types of steels. Tungsten is scratch-resistant but has limited customization and flexibility. Damascus knifemaking material is more durable, rigid, flexible and has better customization.

Damascus Steel vs Titanium

Damascus steel has higher hardness and scratch resistance than titanium. It also has better finishing properties.

Damascus Steel vs German Steel

Damascus steel is known for its looks, blade durability, sharpness and edge retention. German steel also has comparable durability and chipping resistance. hardness is better in German steel

Applications: Finding the Perfect Match

- Damascus steel

Damascus steel is a well-known knifemaking material. It has a combination of ductility and hardness and is a high-performance steel. Damascus blade material is designed with a wavy feature. This meets at the edge of blade and determines the cutting performance of knife. This implies these blade materials are specifically designed for hunting, cooking, cutting, chopping or fishing.

it is also employed in making utensils and cookware because it has a unique aesthetics and durability.

Other than the kitchen items, Damascus steel has found another application, recently, this is in the manufacturing of firearms components. These are like barrels and triggers due to high strength and flexibility.

- Stainless steel

stainless steel is a commonly used in kitchen accessories such as cutlery, utensils. It has higher corrosion resistance, durability and easy to clean.

It is also employed in industries like food preparation and processing, catering equipment, and in distillation due to easy-to-clean nature.

stainless steel is a widely used material in construction for building faces, railing and all the architectural parts due to higher structural properties and being a high-performance steel.

Sharpening and Maintenance Techniques

- Damascus steel

Sharpening techniques: it is important to maintain the blade durability of Damascus knives. Japanese whetstone is mostly used to sharpen the blade material.

Cleaning techniques: proper rinsing the blade after use in a running water is a basic cleaning method. Use a soapy water, soak the knife and then rinse it with water

Maintenance technique: regular cleaning, correctly sharpening and avoid using hard water ot rinse the blade material to maintain the edge retention and blade durability.

- stainless steel

stainless steel is the most flexible material to handle, use, clean and maintain. It is easy to clean and does not require any special treatment. The sharpness of blade material can be sustained by rubbing it over Japanese whetstone. Keep the angle persistent and hold the blade at one angle on each stroke.

CNC Machining Damascus and Stainless Steel

Damascus steel

- CNC machining techniques: when machining Damascus steel, it is required to employ carbide tools. Maintain an appropriate speed and feeding rate to avoid issues.

- Non-hardened billets: when a non-hardened billet is sued in machining, the CNC machining project results better specifically for decorative purposes.

- Vacuum fusion: it is recommended to fuse the Damascus steel under vacuum before machining. This prevents peeling and ensures high-performance steel for any project.

Stainless steel

- CNC machining: stainless steel CNC machining involves precise cutting and shaping of material. This is carried out by computer-aided tools which provides higher accuracy.

- Challenges: common CNC machining challenges in stainless steel are tool wear because of high hardness of material. this requires special tools and techniques to CNC machine the part.

- Machining tips: use proper speed, feeding rate, lubrication to avoid issues and to ensure effective results and a high-performance steel

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

T651 Aluminum: 6061 and 7075 Properties, Uses, Difference

T651 Aluminum: 6061 and 7075 Properties, Uses, Difference