T651 Aluminum: 6061 and 7075 Properties, Uses, Difference

Aug 07,2024

Aug 07,2024

Aluminum is a shiny, lightweight metal used in many things we see daily. Two common types of aluminum are 6061-T651 and 7075-T651. They are both strong, but they have different properties and uses. Let's explore these two types of aluminum in detail. Of course, we will also introduce aluminum T6 VS T651 VS T6511, and carefully analyze the characteristics of the alloy materials.

What is 6061-T651 Aluminum?

6061-T651 aluminum is a type of aluminum that is strong and simple to work with. It doesn&rsquo t rust easily, which makes it a beneficial choice for many applications. 6061-T651 as tough but flexible plastic. You can bend and shape it into different forms.

6061 T651 Aluminum Equivalent

A special process creates 6061-T651 aluminum. It involves heating the metal, then cooling it quickly, and finally letting it age. People often compare it to another type of aluminum known as 6061-T6. Both are similar, but they go through slightly different treatments to become strong.

Common Forms of 6061-T651 Aluminum

You can form 6061-T651 aluminum into a variety of shapes. Each shape serves a distinct purpose.

- Plate:The plate is both flat and It is used to create robust parts such as machine bases and structural components.

- Sheet:The sheet is thin and Panels or covers use it.

- Bar:This is long and It is used for cutting and shaping rods or bars. [2]

What is 7075-T651 aluminum?

Another type of aluminum, 7075-T651, is even stronger than 6061-T651. However, it can rust a little more easily. This makes it perfect for very demanding uses. People frequently use it in airplane parts for strength.

7075 T651 Aluminum Equivalent

Similar to 6061-T651, a special process also produces 7075-T651 aluminum. This process enhances the material's strength. Sometimes, it is compared with 7075-T6 aluminum. They are similar but made with different treatments.

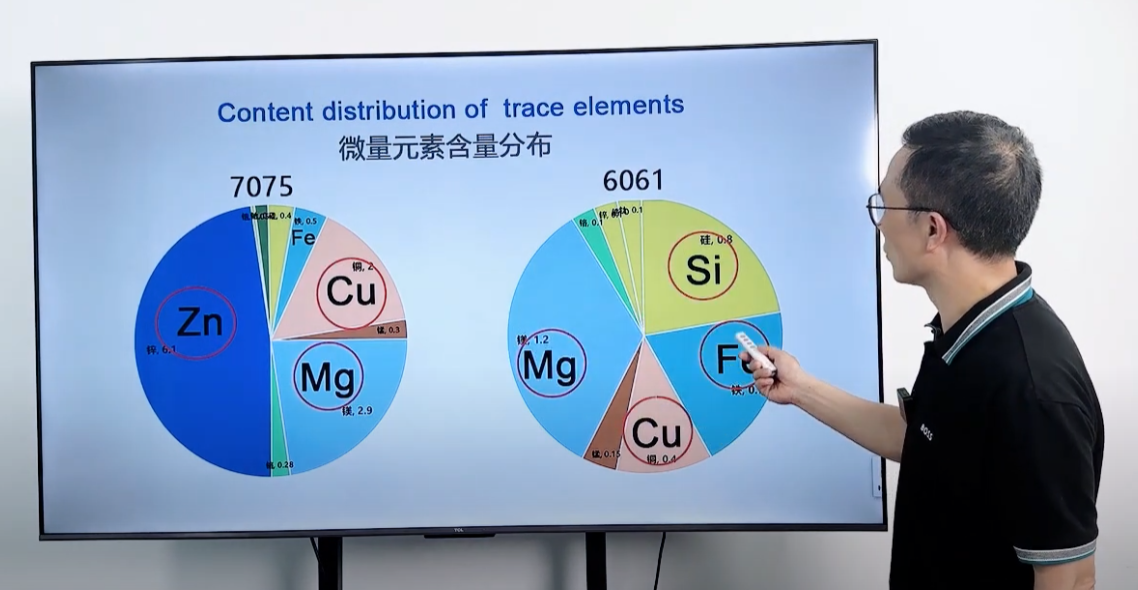

Composition of 6061-T651 and 7075-T651 Aluminum

Different ingredients make up 6061-T651 and 7075-T651. These include metals like magnesium, silicon, and zinc. The combination of these metals alters how aluminum behaves. For example, it affects its strength and how well it resists rust.

|

Element |

6061-T651 |

7075-T651 |

|

Aluminum (Al) |

90.7% - 95.7% |

87.1% - 91.4% |

|

Silicon (Si) |

0.40% - 0.80% |

≤ 0.40% |

|

Iron (Fe) |

≤ 0.70% |

≤ 0.50% |

|

Copper (Cu) |

0.15% - 0.40% |

1.2% - 1.8% |

|

Manganese (Mn) |

0.15% - 0.40% |

≤ 0.30% |

|

Magnesium (Mg) |

0.80% - 1.20% |

2.1% - 2.9% |

|

Chromium (Cr) |

0.04% - 0.35% |

0.18% - 0.28% |

|

Zinc (Zn) |

≤ 0.25% |

5.1% - 6.1% |

|

Titanium (Ti) |

≤ 0.20% |

≤ 0.20% |

|

Other Elements |

Balance (Trace amounts) |

Balance (Trace amounts) |

Corrosion Resistance

6061-T651 aluminum is better at resisting rust than 7075-T651 aluminum. This implies that it can withstand exposure to water without experiencing damage as quickly. Boats and marine parts, exposed to water, use as an example.

Temper Designation: T651

Both 6061-T651 and 7075-T651 aluminum have a special treatment called T651. This treatment makes the aluminum strong and stable. It involves heating the metal, cooling it quickly, and then letting it age.

Here is a video showing 6061 vs 7075 aluminum difference and comparison which would help for understanding further information.

https://youtu.be/2jR_bJjI_OE?si=V11bcV2f1pSus-Pz

Physical Properties

Here&rsquo s how 6061-T651 and 7075-T651 aluminum compare in terms of physical properties. These properties include density, melting point, and conductivity.

|

Property |

6061-T651 |

7075-T651 |

|

Density (kg/m³ ) |

2,700 |

2,810 |

|

The melting point (° C) |

582-6652 |

477-6635 |

|

Electrical conductivity (S/m) |

2.5 × 10⁷ |

1.9 × 10⁷ |

|

Thermal Conductivity (W/(m· K)) |

167 |

130 |

|

Magnetism (T) |

Non-magnetic |

Non-magnetic |

|

Hardness |

Medium |

High |

This shows that 7075-T651 is slightly heavier and harder, making it more resistant to scratches and dents compared to 6061-T651, which has a higher melting point and better electrical and thermal conductivity. Both types of aluminum are non-magnetic.

Mechanical Properties

6061 and 7075 T651 have different mechanical properties. These properties include strength, durability, and elongation.

|

Property |

6061-T651 |

7075-T651 |

|

Strength |

Good |

Very Good |

|

Durability |

High |

Medium |

|

Tensile Strength |

310 MPa |

572 MPa |

|

Yield Strength |

276 MPa |

503 MPa |

|

Elongation |

12% |

11% |

- Strength:The 7075-T651 is stronger than the 6061-T651. This means it can handle more force without breaking.

- Durability:6061-T651 is more durable, meaning it can last longer under

- TensileStrength: This measures how much stretching force the aluminum can handle before 7075-T651 has higher tensile strength.

- YieldStrength: This measures how much force the aluminum can handle before it starts to 7075- T651 has a higher yield strength

- Elongation:This measures how much the aluminum can stretch before 6061- T651 stretches a bit more than 7075-T651 [7]

6061 T651 and 7075 T651 Aluminum Modulus of Elasticity

The modulus of elasticity shows how much the material can stretch. 6061-T651 is more flexible whereas, 7075-T651 is stiffer and doesn&rsquo t bend as much. This dimensionally stable aluminum characteristic is crucial for specific applications.

Hardness and fatigue resistance

The 7075-T651 is harder and can handle more wear and tear. It is better suited for items that receive frequent use. The 6061 T651 aluminum chemical composition provides a good balance of hardness and flexibility.

Stress, corrosion, and crack resistance

6061-T651 is better at resisting stress and rust cracks. This makes it a superior option for environments that may experience stress or exposure to water. Its dimensionally stable aluminum properties ensure it maintains its shape under various conditions.

Machinability and weldability of 6061 T651 vs 7075 T651

The ease of machining and shaping a material is known for its machinability. Weldability describes the ease of joining it to other pieces through welding. Here&rsquo s how they compare:

| Property | 6061 T651 | 7075 T651 |

|---|---|---|

| Machinability | Excellent. 6061 T651 is highly machinable with good surface finish and chip control. It's often used for complex shapes and high precision machining. | Good. 7075 T651 is also machinable but tends to produce longer chips and requires more rigid tooling and setups. |

| Weldability | Good. 6061 T651 is known for its good weldability. It can be welded using all common techniques. However, its mechanical properties can be reduced in the weld zone. | Poor. 7075 T651 has poor weldability due to its susceptibility to cracking and loss of strength in the weld zone. It's typically not recommended for welded structures. |

The 6061 T651 aluminum chemical composition allows for ease of machining and welding.

What is the Difference Between 6061 T651 and 7075 T651?

- Strength:7075-T651 is a lot stronger than 6061-T651.

- Corrosion Resistance: 6061-T651 is more resistant to rust than 7075-T651.

- Workability:The 6061-T651 is easier to use than the 7075-T651.

Try Tuofa Now!

Custom solutions for complex designs: send drawings to info@tuofa-cncmachining.com

Real human quotes are more accurate than software quotes

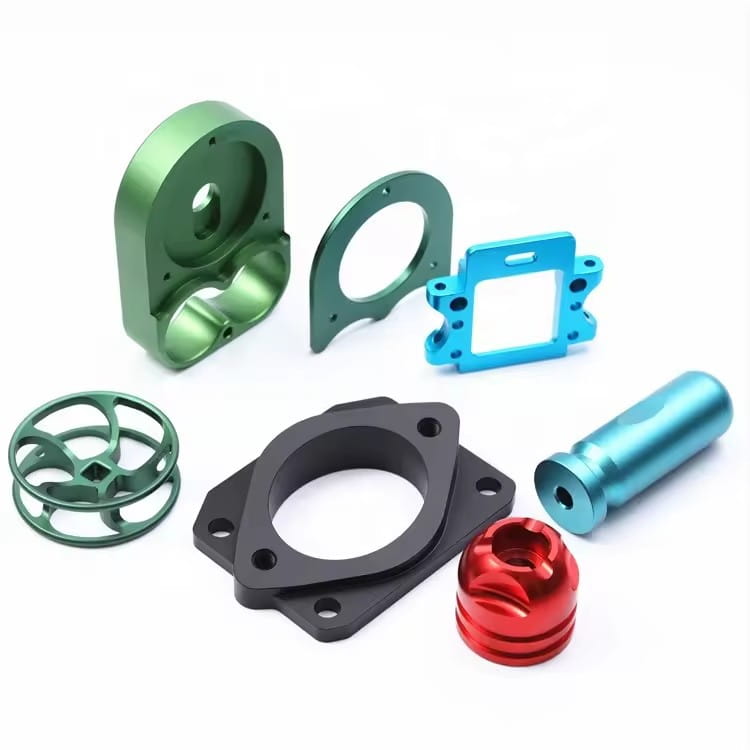

6061 T651 and 7075 T651 Uses

Here are some common applications for 6061-T651 and 7075-T651:

|

Application |

6061-T651 |

7075-T651 |

|

Airplane Parts |

No |

Yes |

|

Bicycle Frames |

Yes |

No |

|

Car Parts |

Yes |

Yes |

|

Construction |

Yes |

No |

|

Marine Applications |

Yes |

No |

- 7075-T651 are used for strength of aircraft parts.

- 6061-T651is commonly used for its low-distortion aluminum properties and it is favored for its ease of machining and weldability.

- CarParts: Depending on your needs, you can use either

- Construction:We prefer 6061-T651 due to its durability and resistance to

- MarineApplications: The 6061-T651 is used because of its superior water-handling [8]

Other Aluminum Alloy T651 Properties

There are other types of aluminum alloys with different uses:

- 2014T651: Known for its high strength and Parts requiring extreme strength utilize this material.

- 7050T651: Often used in airplanes and aerospace

- Weuse 6082 T651 for construction and

Is 6061-T651 better than 7075-T651?

It depends on what you need.

- 7075-T651:Ideal for things that require a lot of strength, such as airplane

- 6061-T651:Best for things that resist rust and are simple to work with, like bicycle frames and marine

6061-T651 aluminum and 7075-T651 aluminum have better properties that make them suitable for different applications. Understanding their chemical compositions, mechanical properties, and thermal stress relief treatments can help you choose the right type of aluminum for your needs. Whether you require low-distortion aluminum, dimensionally stable aluminum, or materials resistant to stress corrosion, both 6061-T651 and 7075-T651 offer valuable option.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Comparing the Quoting Processes of Xometry and Tuofa

Comparing the Quoting Processes of Xometry and Tuofa